Preparation method and application of water-soluble fluorine-containing acrylic resin

An acrylic resin, water-soluble fluorine-containing technology, applied in coatings and other directions, can solve the problem of high price, and achieve the effect of high utilization rate of raw materials, good chemical resistance and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

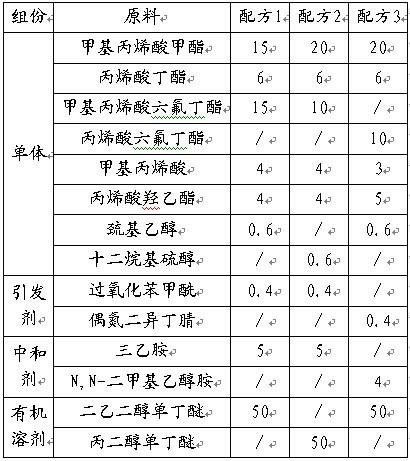

[0032] For the specific formula, see formula 1 in Table 1, and the operation steps are as follows.

[0033] According to formula 1, first add 30 parts of diethylene glycol monobutyl ether, 1.2 parts of methyl methacrylate, 0.48 parts of butyl acrylate, 1.2 parts of hexafluorobutyl methacrylate, 0.32 parts of methacrylic acid into the reactor, 0.32 parts of hydroxyethyl acrylate, 0.048 parts of mercaptoethanol, and 0.12 parts of benzoyl peroxide; the temperature was raised to 85° C. for 20 minutes, and the above-mentioned parts were by weight.

[0034] Then, add 20 parts of diethylene glycol monobutyl ether, 13.8 parts of methyl methacrylate, 5.82 parts of butyl acrylate, 13.8 parts of hexafluorobutyl methacrylate, 3.68 parts of methacrylic acid, hydroxyethyl acrylate 3.68 parts of esters, 0.552 parts of mercaptoethanol, and 0.28 parts of benzoyl peroxide; stir evenly, and drop them into the reactor within 3 to 4 hours. After continuing to keep warm at 80-85°C for 1 hour, lowe...

Embodiment 2

[0037] For the specific formula, see formula 2 in Table 1, and the operation steps are as follows.

[0038] According to formula 2, first add 30 parts of propylene glycol monobutyl ether, 1.6 parts of methyl methacrylate, 0.48 parts of butyl acrylate, 0.8 parts of hexafluorobutyl methacrylate, 0.32 parts of methacrylic acid, and 0.32 parts of methacrylic acid into the reactor. 0.32 parts of esters, 0.048 parts of dodecyl mercaptan, and 0.12 parts of benzoyl peroxide; the temperature was raised to 85° C. for 20 minutes, and the above-mentioned parts were by weight.

[0039] Then add 20 parts of propylene glycol monobutyl ether, 18.4 parts of methyl methacrylate, 5.82 parts of butyl acrylate, 9.2 parts of hexafluorobutyl methacrylate, 3.68 parts of methacrylic acid, and 3.68 parts of hydroxyethyl acrylate into the dripping cylinder. parts, 0.552 parts of dodecyl mercaptan, and 0.28 parts of benzoyl peroxide; stir evenly, and drop them into the reactor within 3 to 4 hours. After...

Embodiment 3

[0042] For the specific formula, refer to formula 3 in Table 1, and the operation steps are as follows.

[0043] First, add 30 parts of diethylene glycol monobutyl ether, 1.6 parts of methyl methacrylate, 0.48 parts of butyl acrylate, 0.8 parts of hexafluorobutyl acrylate, 0.24 parts of methacrylic acid, and 0.4 parts of hydroxyethyl acrylate into the reactor , 0.048 parts of mercaptoethanol, and 0.12 parts of azobisisobutyronitrile; the temperature was raised to 85° C. for 20 minutes, and the above-mentioned parts were by weight.

[0044] Then into the dropper, add 20 parts of diethylene glycol monobutyl ether, 18.4 parts of methyl methacrylate, 5.82 parts of butyl acrylate, 9.2 parts of hexafluorobutyl acrylate, 2.76 parts of methacrylic acid, 4.6 parts of hydroxyethyl acrylate parts, 0.552 parts of mercaptoethanol, and 0.28 parts of azobisisobutyronitrile; stir evenly, and drop them into the reactor within 3 to 4 hours. After continuing to keep warm at 80-85°C for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com