Boron-doped glass carbon material and preparation method thereof

A technology of glassy carbon and boron doping, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of complex production process, long production cycle, single specification, etc., and achieve dense and uniform structure, excellent Antioxidant performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

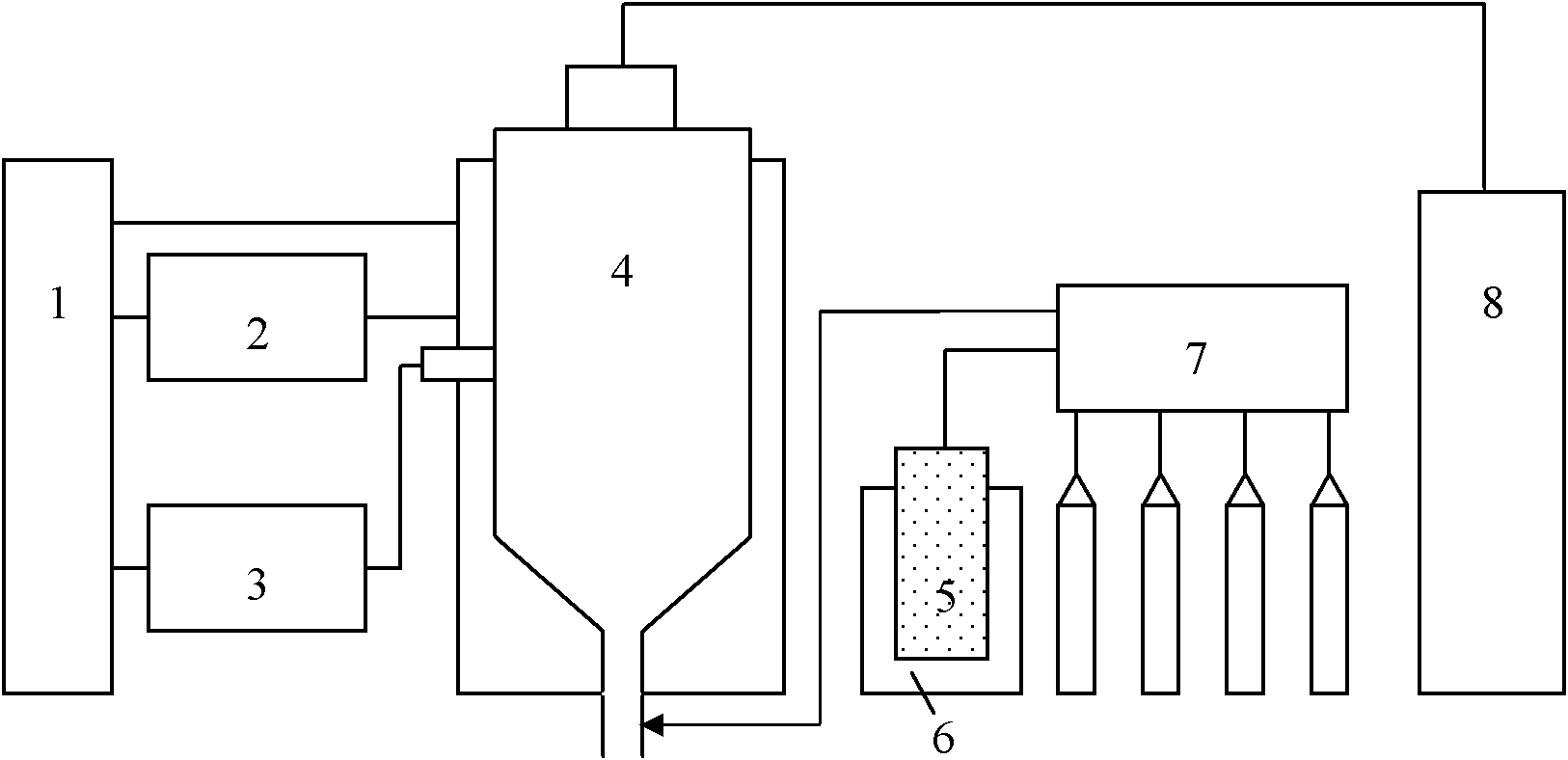

Method used

Image

Examples

Embodiment 1

[0029] The deposition temperature is 1200° C., the flow rate of propane gas is 100 mL / min, the flow rate of boron trichloride gas is 150 mL / min, and the flow rate of hydrogen gas is 500 mL / min. The deposition substrate is a graphite tube with an inner diameter of 30 mm and a polished inner surface. In this embodiment, the reaction time is 1 hour, and a boron-doped glassy carbon inner coating material is obtained, the coating thickness is about 1 mm, and the boron doping amount is 5.1 at.%.

[0030] like figure 2 As shown, observed under a metallographic microscope, the prepared glassy carbon has a dense structure, very few pores, no growth characteristics, non-optical activity, and is an isotropic material.

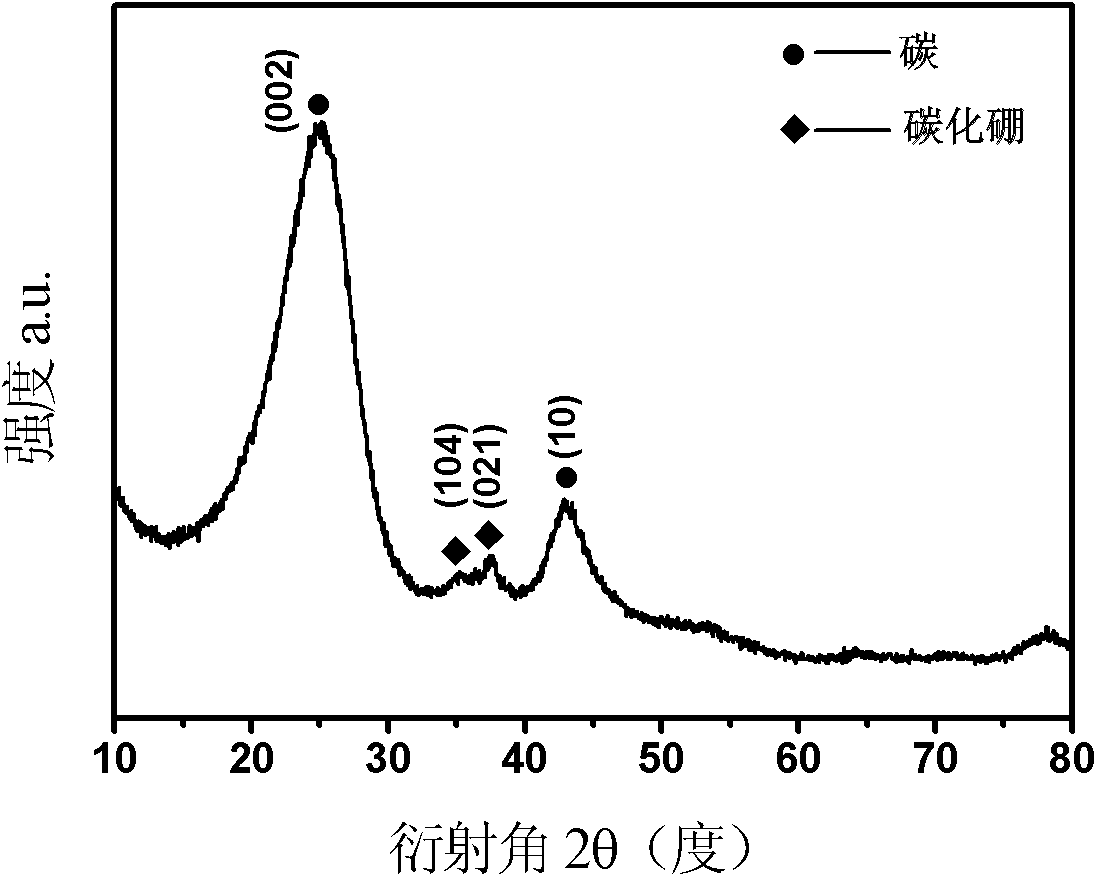

[0031] like image 3 As shown, the X-ray diffraction spectrum of the material indicates that the material is a two-phase mixture of carbon and boron carbide. Among them, glassy carbon has the characteristics of amorphous or turbostratic carbon, while the diffraction p...

Embodiment 2

[0035] The deposition temperature is 1150° C., the flow rate of propane gas is 100 mL / min, the flow rate of boron trichloride gas is 100 mL / min, and the flow rate of hydrogen gas is 500 mL / min. The deposition substrate is a graphite cylinder with a diameter of 15 mm and a length of 40 mm, with a polished surface. In this embodiment, the reaction time is 1 hour, and the inner and outer coating materials of circular boron-doped glassy carbon are obtained, the coating thickness is about 0.5 mm, the boron doping amount is 2.8 at.%, and the boron element is mainly in the form of boron carbide , uniformly distributed in the glassy carbon matrix.

Embodiment 3

[0037]The deposition temperature is 1250° C., the flow rate of propane gas is 100 mL / min, the flow rate of boron trichloride gas is 80 mL / min, and the flow rate of hydrogen gas is 700 mL / min. The deposition substrate is a graphite plate with a length of 60 mm, a width of 30 mm, and a thickness of 4 mm, and the surface is polished. In this embodiment, the reaction time is 2 hours, and a boron-doped flat glassy carbon coating material is obtained. The coating thickness is about 1.5 mm, and the boron doping amount is 3.1 at.%, and the boron element is mainly in the form of boron carbide. uniformly distributed in the glassy carbon matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com