Method for preparing Nafion nanometer filter film

A nanofiber membrane and solution technology, which is applied in fiber processing, spinning solution preparation, textile and papermaking, etc., can solve the problems of complicated and time-consuming removal of templates, and achieves a simple method, good thermal stability, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: the preparation method of a kind of Nafion nanofiber film of the present invention, the steps are as follows:

[0016] Step 1: Preparation of electrospinning solution: directly dissolve polyethylene oxide with a molecular weight of 90,000 into 5wt% Nafion solution to prepare a solution with a polyethylene oxide concentration of 0.3wt%, and stir at room temperature for 20 hours until the solution is transparent and uniformly dispersed , to obtain a uniform electrospinning solution;

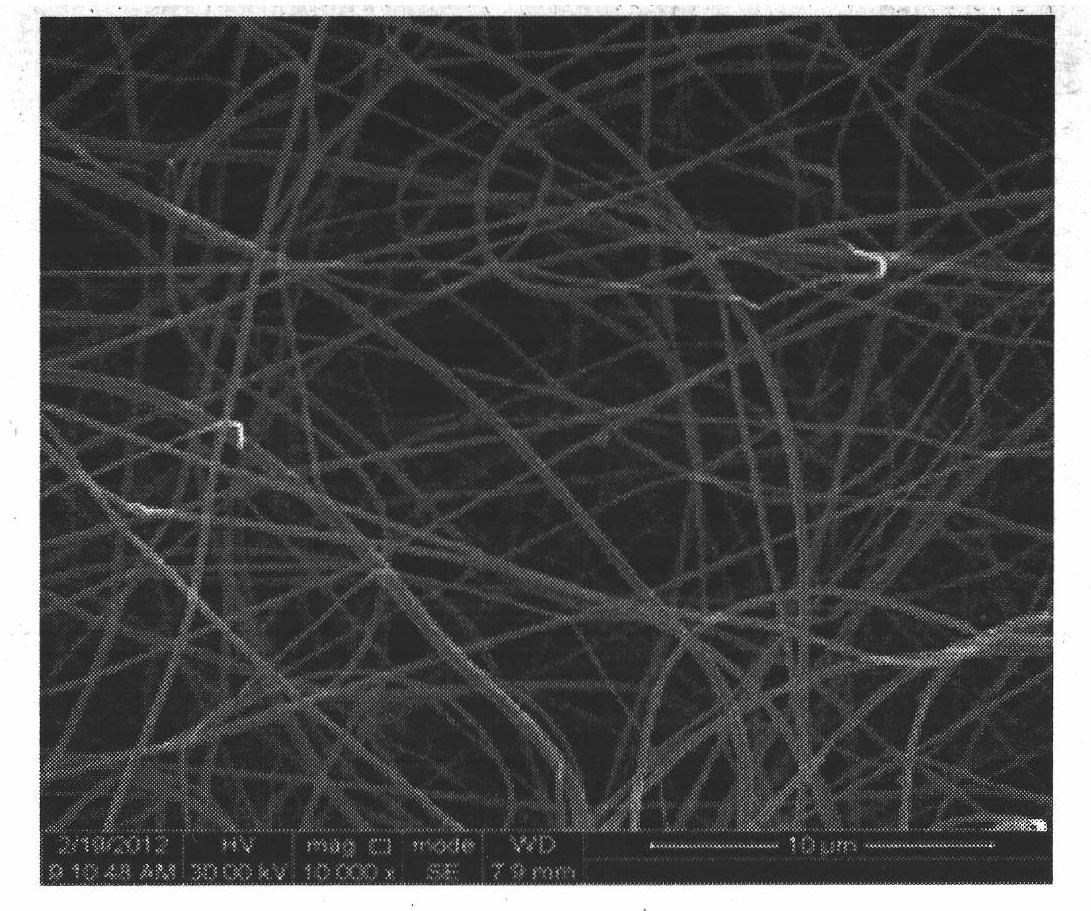

[0017] Step 2: Place the electrospinning solution in the groove of the electrode rod, adjust the rotation speed of the electrode rod to 0.9rpm; the spinning voltage is 30kV, the distance between the spinning electrode rod and the receiving plate is 16cm, and the prepared fiber membrane is placed at room temperature Drying for more than 24 hours, the morphology of nanofibers was observed by scanning electron microscope.

Embodiment 2

[0018] Embodiment 2: the preparation method of a kind of Nafion nanofiber film of the present invention, the steps are as follows:

[0019] Step 1: Preparation of electrospinning solution: Dissolve polyethylene oxide with a molecular weight of 90,000 directly into 5wt% Nafion solution to prepare a solution with a polyethylene oxide concentration of 0.5wt%, and stir at room temperature for 20 hours until the solution is transparent and uniformly dispersed , to obtain a uniform electrospinning solution;

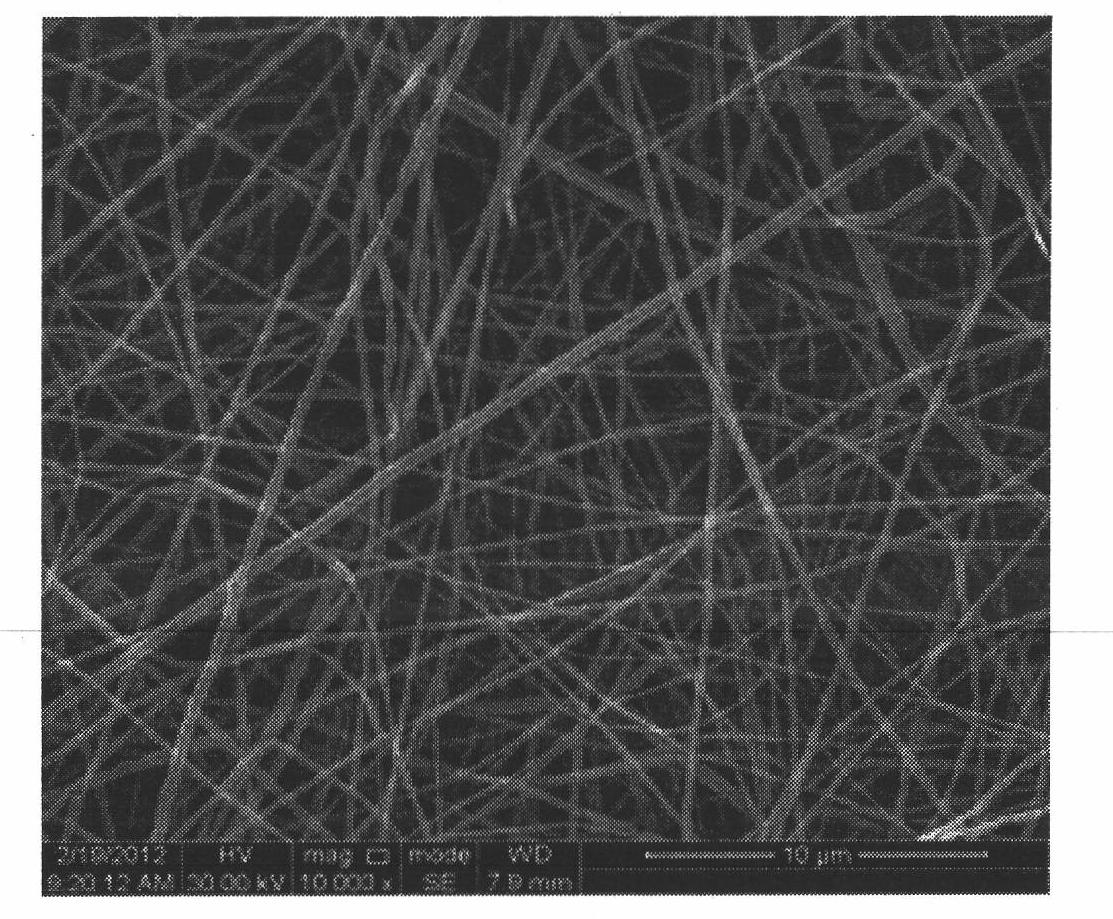

[0020] Step 2: Place the electrospinning solution in the groove of the electrode rod, adjust the rotation speed of the electrode rod to 0.9rpm; the spinning voltage is 30kV, the distance between the spinning electrode rod and the receiving plate is 16cm, and the prepared fiber membrane is placed at room temperature Drying for more than 24 hours, the morphology of nanofibers was observed by scanning electron microscope.

Embodiment 3

[0021] Embodiment 3: the preparation method of a kind of Nafion nanofiber film of the present invention, the steps are as follows:

[0022] Step 1: Preparation of electrospinning solution: directly dissolve polyethylene oxide with a molecular weight of 90,000 into 5wt% Nafion solution to prepare a solution with a polyethylene oxide concentration of 0.7wt%, and stir at room temperature for 20 hours until the solution is transparent and uniformly dispersed , to obtain a uniform electrospinning solution;

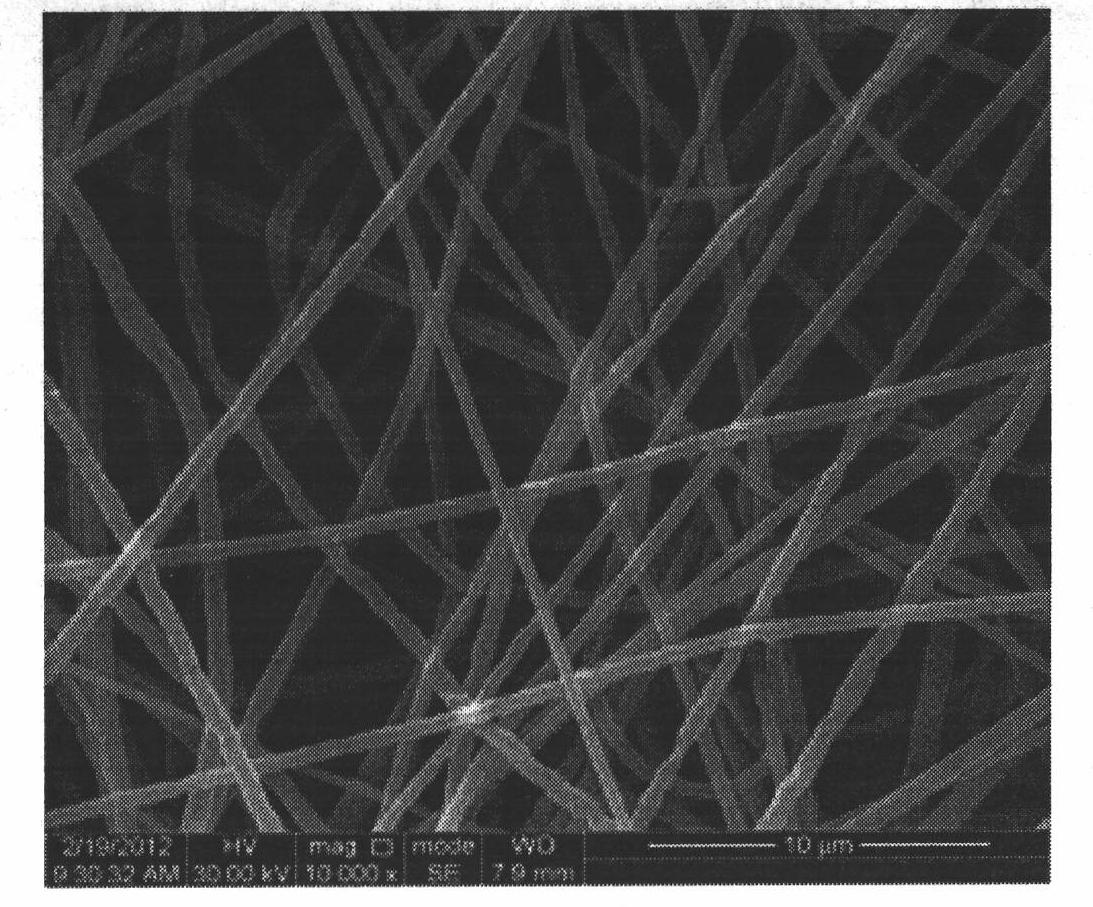

[0023] Step 2: Place the electrospinning solution in the groove of the electrode rod, adjust the rotation speed of the electrode rod to 0.9rpm; the spinning voltage is 30kV, the distance between the spinning electrode rod and the receiving plate is 16cm, and the prepared fiber membrane is placed at room temperature Drying for more than 24 hours, the morphology of nanofibers was observed by scanning electron microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com