Use of copper alginate

A technology of copper alginate and sodium alginate, applied in the preparation of organic compounds, organic chemistry, bulk chemical production, etc., to achieve the effects of high conversion rate, low price, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

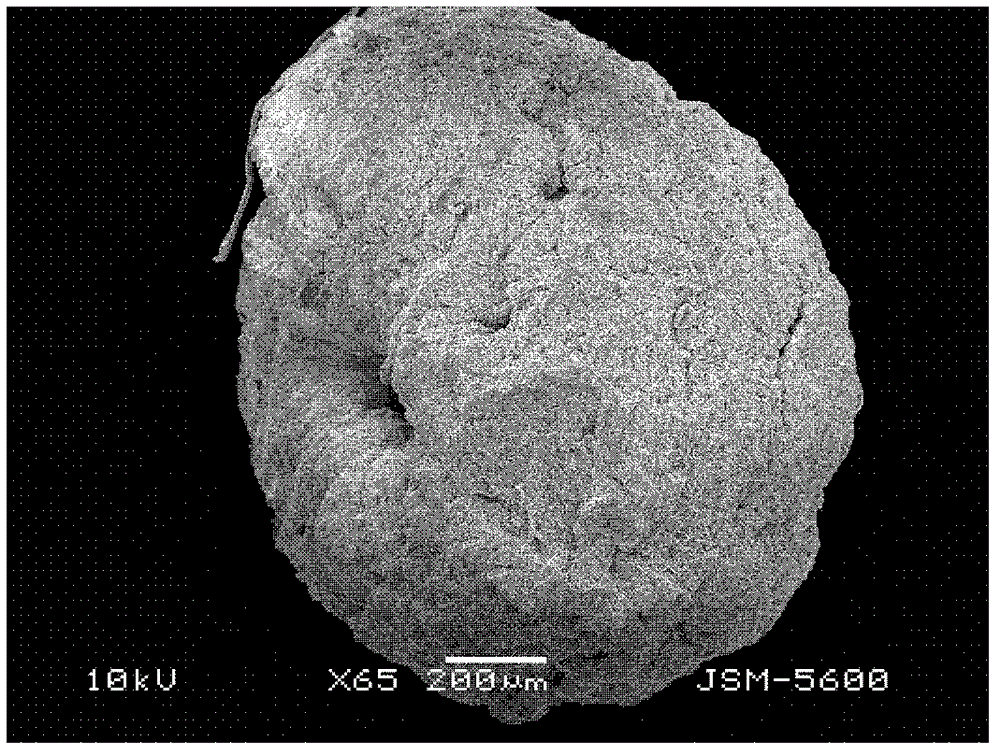

[0017] Example 1 Preparation of copper alginate: Weigh 4.00g sodium alginate and dissolve it in 100mL distilled water, weigh 6.82g CuCl 2 2H 2 O was dissolved in 100mL of distilled water, and sodium alginate was dropped into the copper chloride solution at 50°C and the rotation speed was 20rpm. Wash with water until the filtrate is colorless, and dry in a drying oven at 40°C for 24 hours to obtain copper alginate. The SEM image of dry beaded copper alginate is shown in figure 1 .

[0018] Embodiment 2-8 is the usage embodiment of copper alginate catalyst.

Embodiment 2

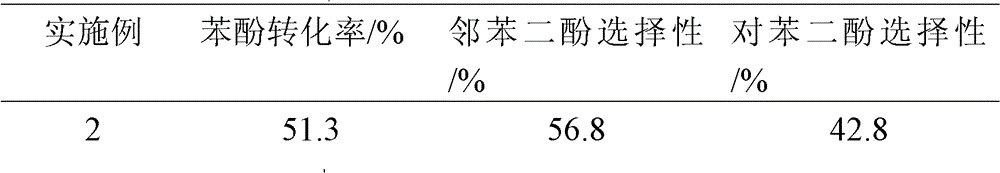

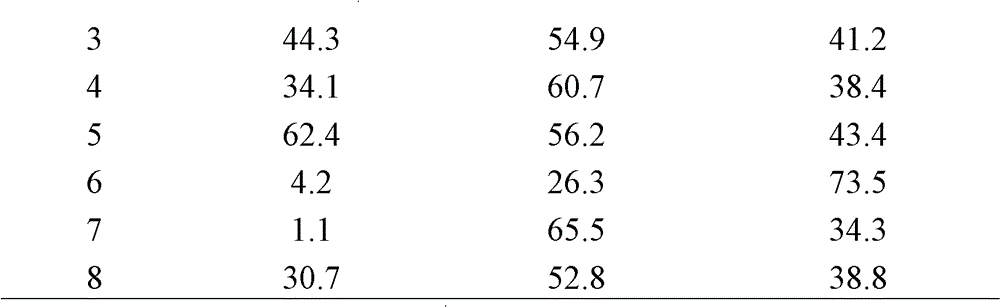

[0019] Embodiment 2: be 20: 1 to take by weighing phenol 1.0g (10mmol), catalyst 50mg by the mass ratio of phenol and catalyzer, be 1: 30 by the proportioning of the mass g of phenol and the volume mL of reaction medium, take by weighing 30mL water ;Put the weighed phenol, catalyst and water in a three-necked flask, place the three-necked flask in a constant temperature water bath, and under magnetic stirring, when the temperature reaches 70°C, weigh the phenol and hydrogen peroxide in a molar ratio of 1:2 Hydrogen peroxide 2mL (20mmol) was added dropwise into the there-necked flask at a rate of 0.1mL / min. After the addition, the timing reaction was started, and the reaction time was 1 hour to obtain the target product. The reaction solution after the reaction in the example was suction-filtered, the catalyst and the reaction solution were separated, the recovered catalyst was washed with ethanol until the washing solution was colorless, and the catalyst was placed in a drying ...

Embodiment 3

[0020] Embodiment 3: be 50: 1 by weighing phenol 1.0g (10mmol), catalyst 20mg by the mass ratio of phenol and catalyst, be 1: 30g / mL by the proportioning of the mass of phenol and the volume of reaction medium, take by weighing 30mL water ;Put the weighed phenol, catalyst and water in a three-necked flask, place the three-necked flask in a constant temperature water bath, and under magnetic stirring, when the temperature reaches 70°C, weigh the phenol and hydrogen peroxide in a molar ratio of 1:3 3mL (30mmol) of hydrogen peroxide was added dropwise in the there-necked flask at a rate of 0.1mL / min. After the addition, the timing reaction was started, and the reaction time was 4 hours to obtain the target product. The reaction solution after the reaction in the example was suction-filtered, the catalyst and the reaction solution were separated, the recovered catalyst was washed with ethanol until the washing solution was colorless, and the catalyst was placed in a drying oven at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com