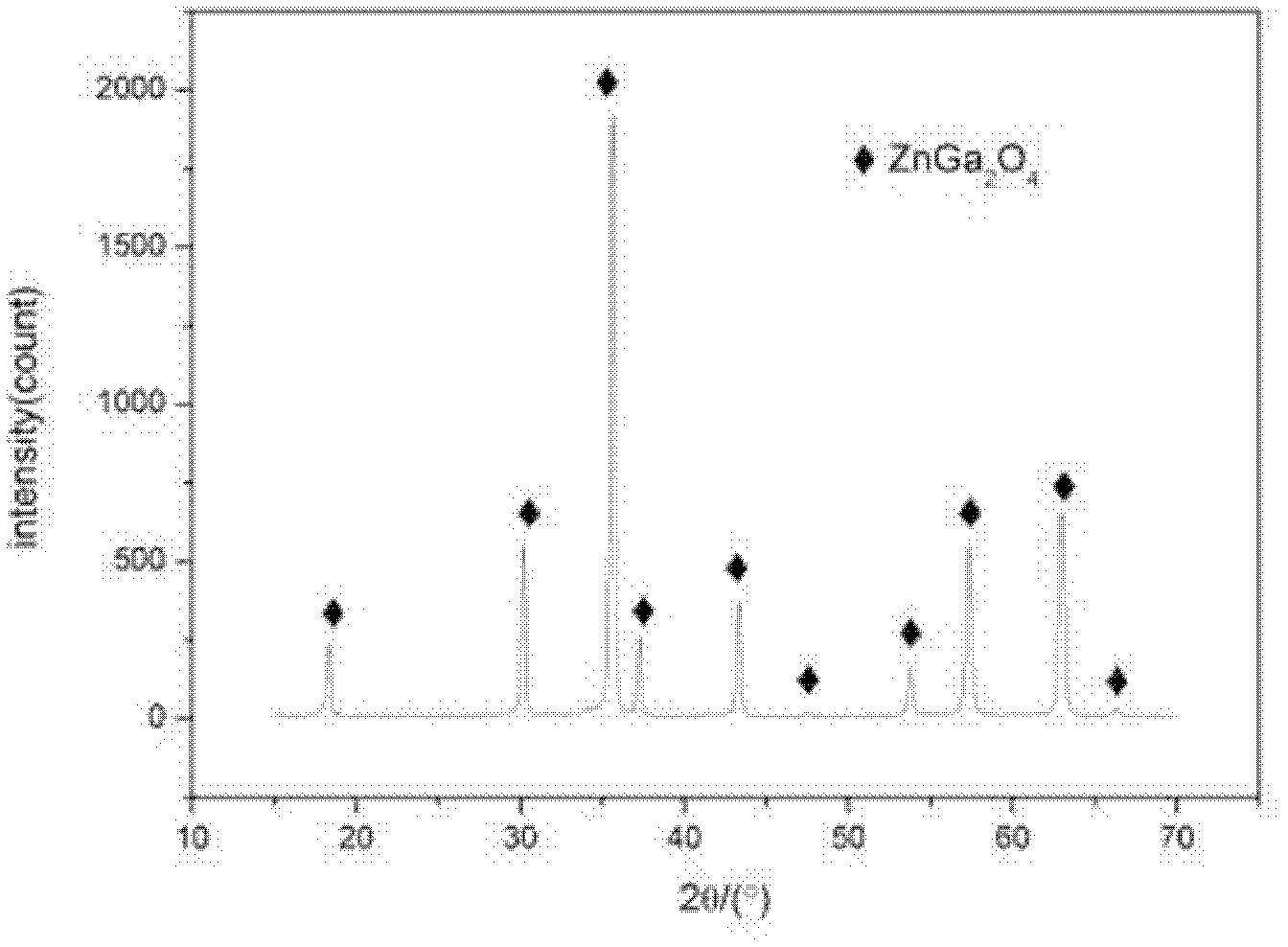

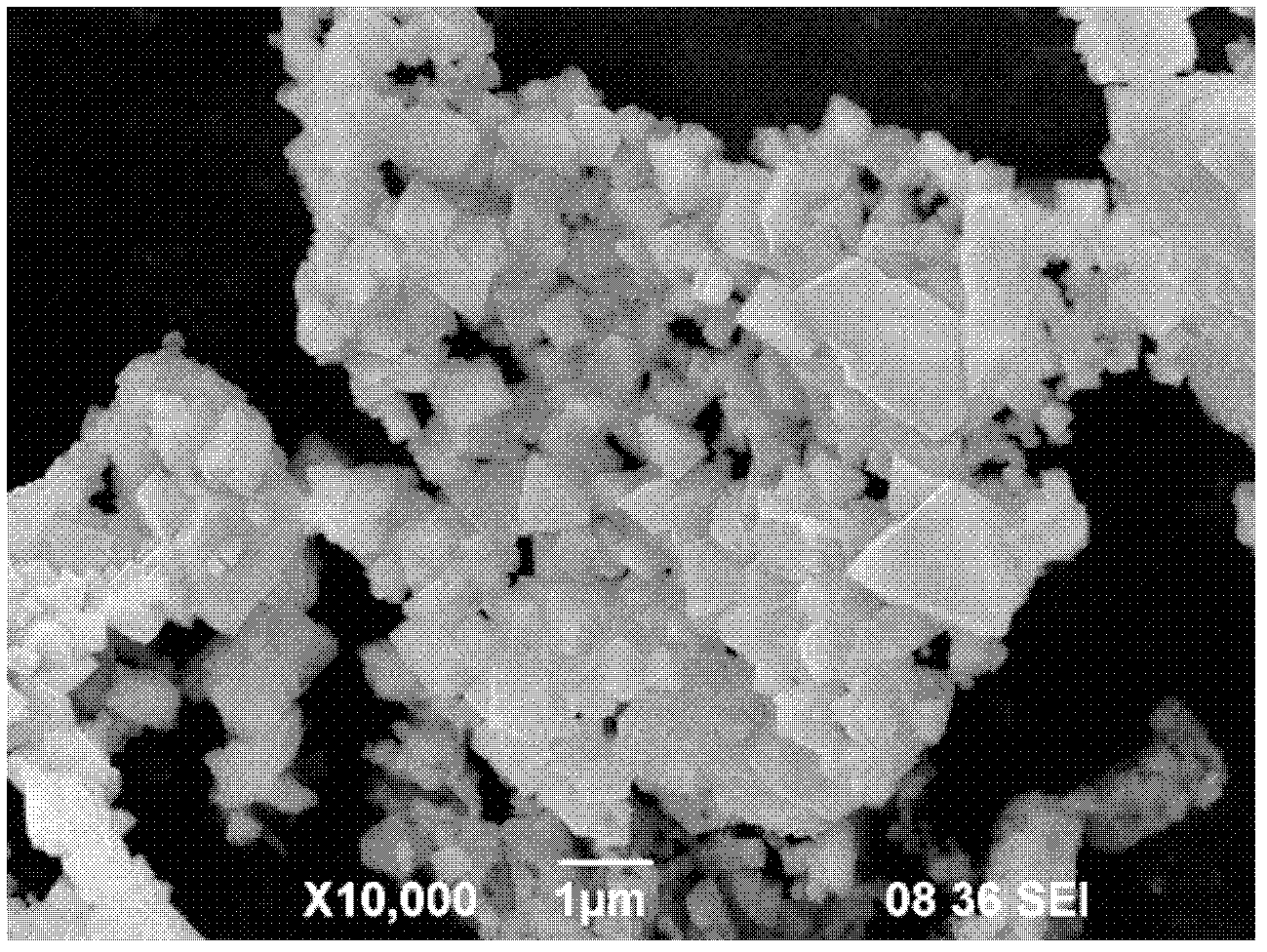

Preparation method for ZnGa2O4 mono-crystal with octahedral structure

An octahedral and single crystal technology is applied in the field of preparation of octahedral ZnGa2O4 single crystals, which can solve the problems of expensive equipment, complicated operation, and inability to prepare, and achieve the effects of low equipment cost, good repeatability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: step one: will analyze pure gallium oxide (Ga 2 o 3 ) was dissolved in the hydrochloric acid of 0.5mol / L, and constantly stirring to make Ga ion concentration is the suspension A of 0.1mol / L;

[0018] Step 2: Zinc acetate (Zn(CH 3 COO) 2 ) was added in distilled water and continuously stirred to prepare a transparent solution B with a Zn ion concentration of 0.1mol / L;

[0019] Step 3: Mix the suspension A and the transparent solution B at a molar ratio of Zn:Ga=1:1.4 and stir evenly, then add Zn+Ga:analytical pure ethylenediaminetetraacetic acid (EDTA)=1 to the mixed solution : Add analytically pure ethylenediaminetetraacetic acid (EDTA) at a molar ratio of 1, adjust the pH=2.5 of the solution with analytically pure sodium hydroxide, and fully stir for 30min to obtain solution C;

[0020] Step 4: Put the solution C under a UV lamp with a wavelength of 365nm to react for 20 minutes, and then react in a microwave reactor for 3 hours until the water evapo...

Embodiment 2

[0023] Embodiment 2: step one: will analyze pure gallium oxide (Ga 2 o 3 ) is dissolved in the hydrochloric acid of 0.7mol / L, and constantly stirring to make Ga ion concentration is the suspension A of 0.3mol / L;

[0024] Step 2: Zinc acetate (Zn(CH 3 COO) 2 ) was added in distilled water and continuously stirred to prepare a transparent solution B with a Zn ion concentration of 0.1mol / L;

[0025] Step 3: Mix the suspension A and the transparent solution B at a molar ratio of Zn:Ga=1:1.6 and stir evenly, then add Zn+Ga:analytical pure ethylenediaminetetraacetic acid (EDTA)=1 to the mixed solution : Add analytically pure ethylenediaminetetraacetic acid (EDTA) at a molar ratio of 1, adjust the pH=3 of the solution with analytically pure sodium hydroxide, fully stir for 40min to obtain solution C;

[0026] Step 4: Put the solution C under a UV lamp with a wavelength of 365nm to react for 10 minutes, and then react in a microwave reactor for 3 hours until the water evaporates t...

Embodiment 3

[0028] Embodiment 3: step one: will analyze pure gallium oxide (Ga 2 o 3 ) was dissolved in the hydrochloric acid of 0.3mol / L, and constantly stirring to make Ga ion concentration is the suspension A of 0.5mol / L;

[0029] Step 2: Zinc acetate (Zn(CH 3 COO) 2 ) was added in distilled water and continuously stirred to prepare a transparent solution B with a Zn ion concentration of 0.1mol / L;

[0030] Step 3: Mix the suspension A and the transparent solution B at a molar ratio of Zn:Ga=1:1.8 and stir evenly, then add Zn+Ga:analytical pure ethylenediaminetetraacetic acid (EDTA)=1 to the mixed solution : Add analytically pure ethylenediaminetetraacetic acid (EDTA) at a molar ratio of 1, adjust the pH=2 of the solution with analytically pure sodium hydroxide, and fully stir for 60min to obtain solution C;

[0031] Step 4: Put the solution C under a UV lamp with a wavelength of 365nm to react for 40 minutes, and then react in a microwave reactor for 2 hours until the water evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com