Preparation method of hydrated sodium antibacterial agent

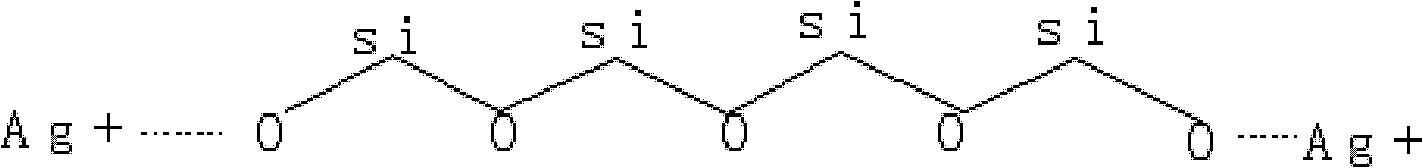

An antibacterial agent and hydration technology, which is applied in the field of preparation of hydrated silicon antibacterial agent, can solve the problems of only 96% antibacterial rate, discoloration preparation process, strict production process, etc., achieve excellent sterilization and antibacterial properties, wide source of raw materials, and good processability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

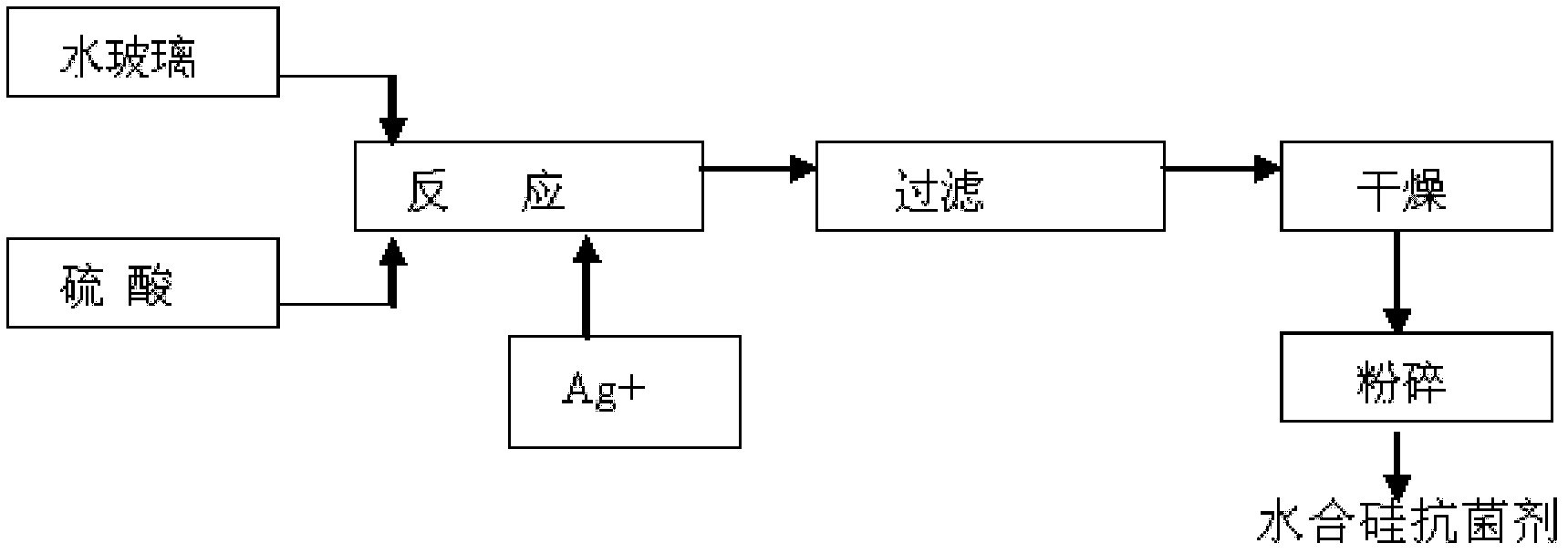

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, a kind of preparation method of hydrated silicon antibacterial agent, comprises the following steps:

[0057] 1), carrier preparation, carry out the following steps successively:

[0058] ①, raw material preparation:

[0059] Water glass and sulfuric acid were prepared with soft water into dilute water glass with a concentration of 2M and dilute sulfuric acid with a concentration of 0.8M respectively for use.

[0060] ②, synthetic preparation:

[0061] Add 210ml of the above-mentioned dilute water glass to the 1-liter reaction kettle, raise the temperature to 30°C, start stirring (stirring is subject to full mixing of the materials, and the stirring speed is 300r / min), constant stirring is controlled, according to the total amount of dilute sulfuric acid. The volume ratio of the amount and the dilute water glass is 1: 1.8, so that the added amount of dilute sulfuric acid is calculated to be 116.7ml; start the dilute sulfuric acid that the above-mentioned...

Embodiment 2

[0075] Embodiment 2, a kind of preparation method of hydrated silicon antibacterial agent,

[0076] In step ① of step 1): change the concentration of dilute water glass to 1.35M, and change the concentration of dilute sulfuric acid to 0.6M; in step ②: change the volume ratio of acid and alkali to 1:1.2; add acid three times speed remains unchanged. Therefore, the first acid addition time is about 35 minutes, the second acid addition time is about 15 minutes, and the third acid addition time is about 63 minutes, for a total of 113 minutes.

[0077] In step 2): change the molar ratio of silver nitrate to silica (hydrated silicon) in the slurry to: 1:28.5;

[0078] The rest are the same as in Example 1.

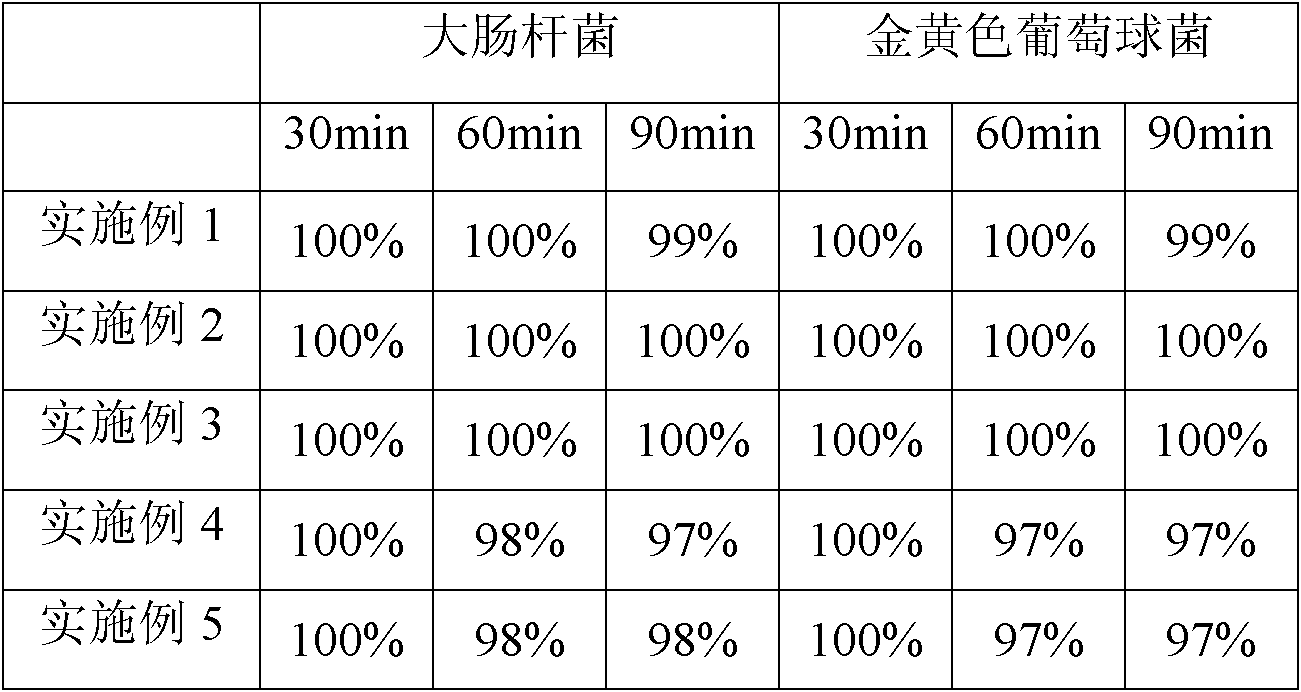

[0079] The hydrated silicon antibacterial agent has been tested and the performance data are as follows:

[0080] Appearance whiteness: 90, SiO 2 : 95.5%, silver ion content is 3.6%, specific surface area is 180m 2 / g, the oil absorption rate DBP is 338ml / 100g, the dispersi...

Embodiment 3

[0081] Embodiment 3: a kind of preparation method of hydrated silicon antibacterial agent,

[0082] In step ① of step 1): change the concentration of dilute water glass to 1.35M, and change the concentration of dilute sulfuric acid to 0.6M; in step ②: change the volume ratio of acid and alkali to 1:1.6; add acid three times speed remains unchanged. Therefore, the first acid addition time is about 26 minutes, the second acid addition time is about 11 minutes, and the third acid addition time is about 47 minutes, for a total of 84 minutes.

[0083] In step 3., be warming up to 98 ℃ constant, add the dilute sulfuric acid that concentration is 0.6M to carry out post-acidification treatment, stop adding above-mentioned dilute sulfuric acid until the pH of solution is 2.5; Then at 98 ℃ of stirring and aging 20min;

[0084] In step 2):

[0085] Change the molar ratio of silver nitrate to silicon dioxide (hydrated silicon) in the slurry: 1:38;

[0086] The rest are the same as in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com