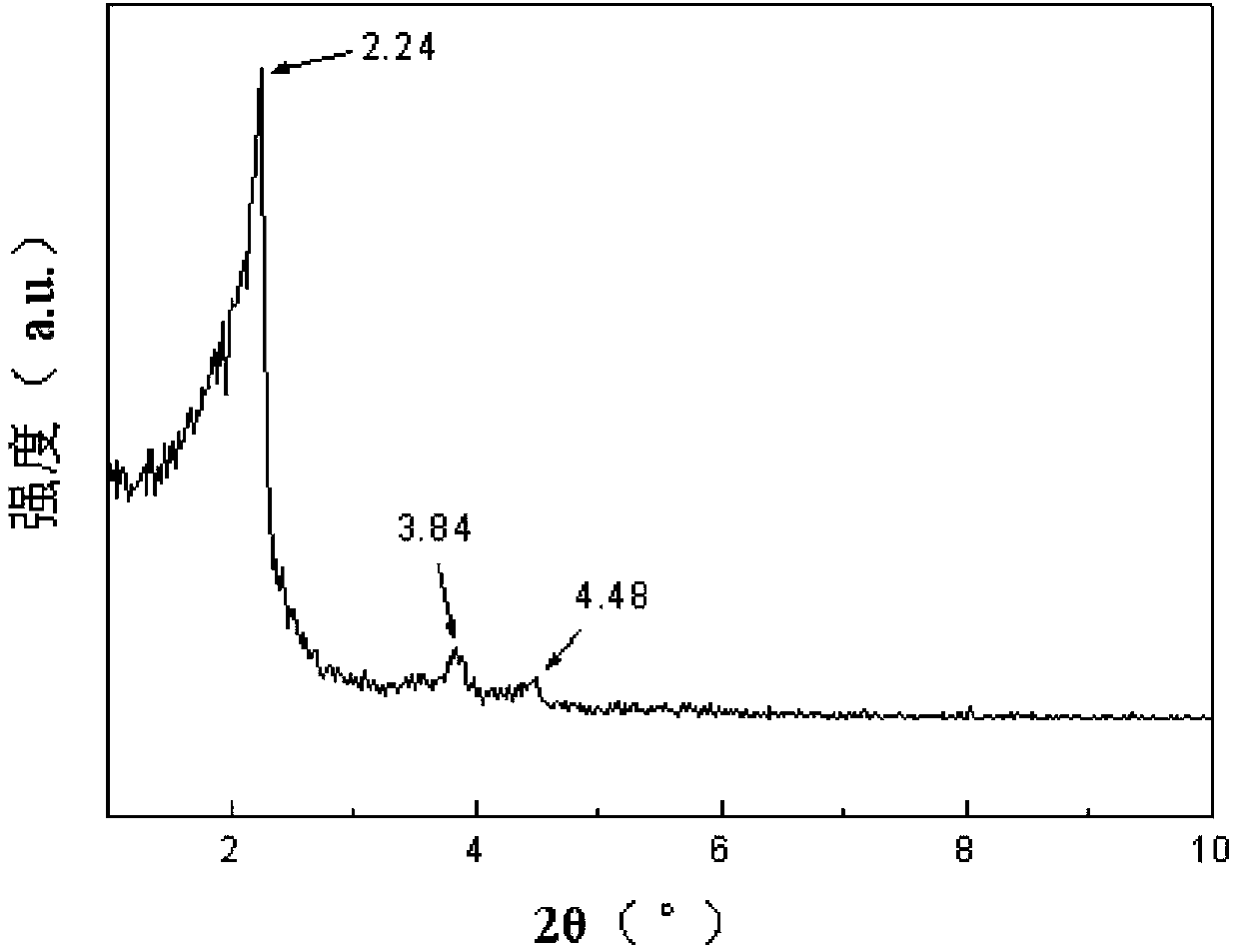

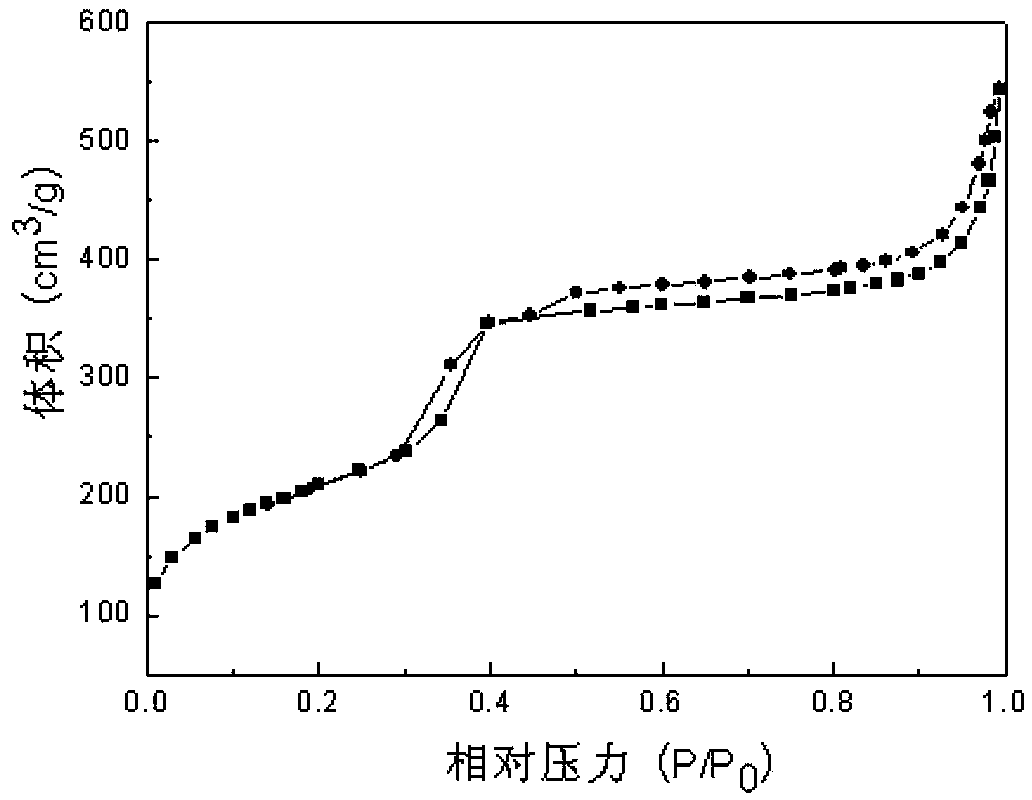

Method for preparing mesoporous titanium silicon molecular sieve nanoparticles

A titanium-silicon molecular sieve, nanoparticle technology, applied in molecular sieve catalysts, nanotechnology, chemical instruments and methods, etc., can solve the problems of limited application, catalytic performance can not be well exerted, and the contact frequency of reactants and reactive centers Low and other problems, to achieve the effect of reducing residence time, environmental pollution-free preparation cycle, and increasing effective collision frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Embodiment 1: A method for preparing mesoporous titanium-silicon molecular sieve nanoparticles according to the present embodiment is carried out according to the following steps:

[0025] 1. Weigh tetraethyl orthosilicate, cetyltrimethylammonium bromide, deionized water, ammonia water and tetrabutyl titanate, hydrogen peroxide and polyquaternium-6 with a mass concentration of 25%, Among them, the molar ratio of ethyl orthosilicate to cetyltrimethylammonium bromide is 1:0.1~0.2, the molar ratio of ethyl orthosilicate to deionized water is 1:50~70, ethyl orthosilicate The mass ratio of ester to ammonia water with a mass concentration of 25% is 1:0.5~3, the molar ratio of ethyl orthosilicate to tetrabutyl titanate is 1:0.01~0.03, and the ratio of ethyl orthosilicate to hydrogen peroxide The molar ratio is 1:0~8, the mass ratio of polyquaternium-6 and cetyltrimethylammonium bromide is 1:0.04~5;

[0026] 2. Add cetyltrimethylammonium bromide, polyquaternium-6, and ammonia ...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the molar ratio of ethyl orthosilicate and cetyltrimethylammonium bromide in step one is 1: 0.11~0.18, and ethyl orthosilicate and The molar ratio of deionized water is 1:55~65, the mass ratio of ethyl orthosilicate to ammonia water with a mass concentration of 25% is 1:1~2, and the molar ratio of ethyl orthosilicate to tetrabutyl titanate 1:0.015~0.25, the molar ratio of tetraethyl orthosilicate to hydrogen peroxide is 1:2~6, the mass ratio of polyquaternium-6 to cetyltrimethylammonium bromide is 1:0.05 ~4.5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the molar ratio of tetraethyl orthosilicate to hexadecyltrimethylammonium bromide in step one is 1:0.15, and tetraethyl orthosilicate and deionized The molar ratio of water is 1:60, the mass ratio of ethyl orthosilicate to ammonia water with a mass concentration of 25% is 1:1.2, the molar ratio of ethyl orthosilicate to tetrabutyl titanate is 1:0.1, and The molar ratio of ethyl silicate to hydrogen peroxide is 1:4, and the mass ratio of polyquaternium-6 to cetyltrimethylammonium bromide is 1:2. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com