Selenized microbial exopolysaccharide, and preparation method and uses thereof

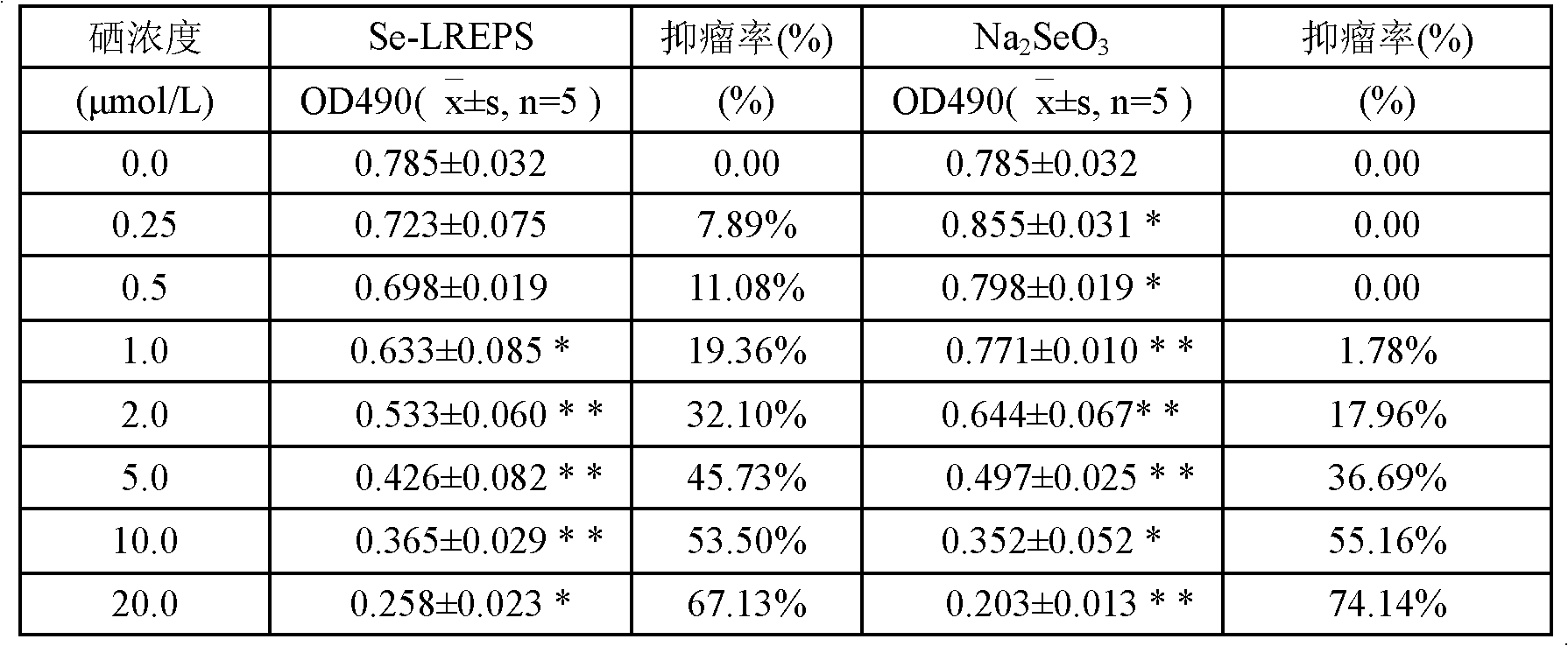

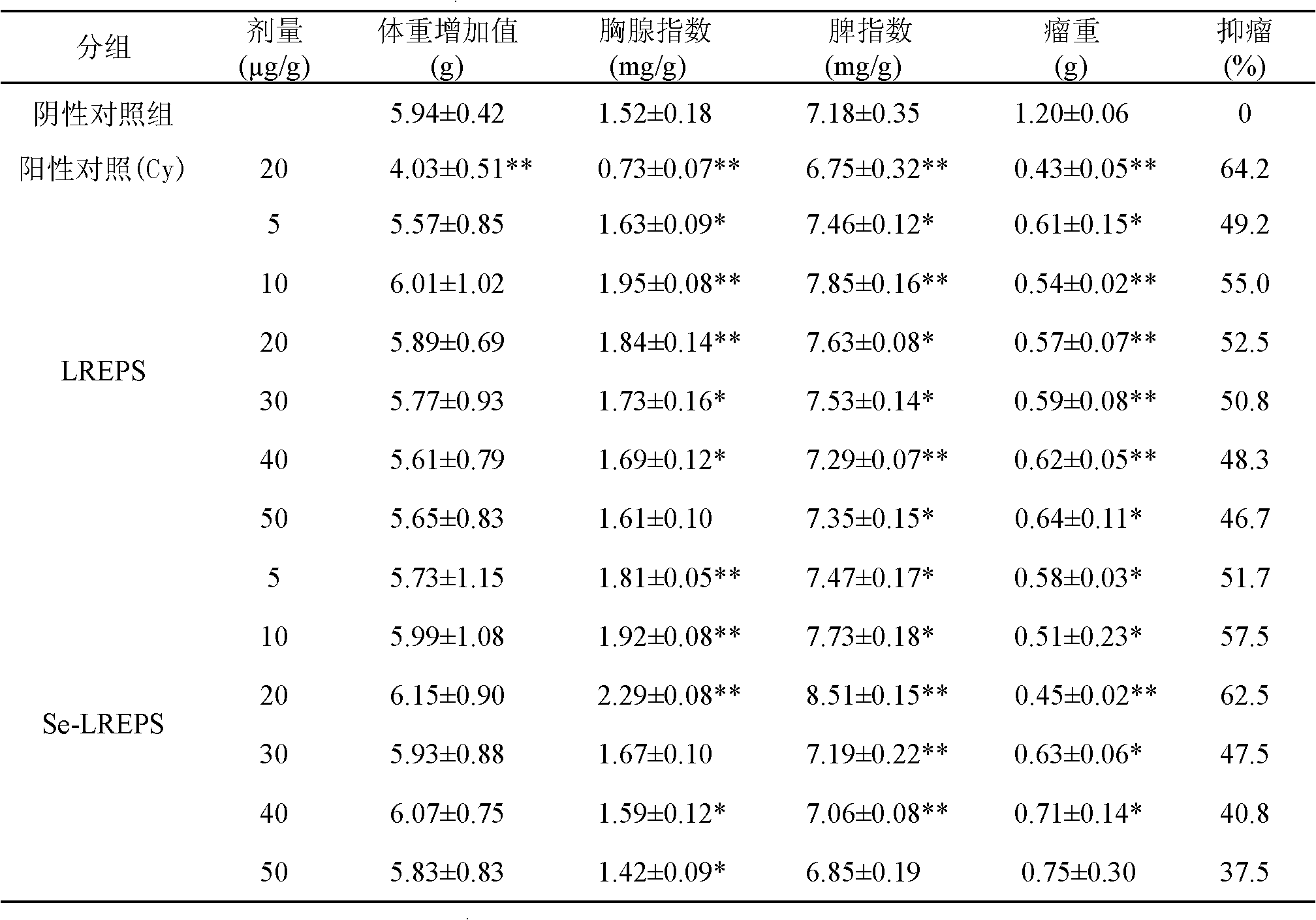

An extracellular polysaccharide and microorganism technology, which is applied in the field of selenized small-molecule microbial exopolysaccharide and its preparation, can solve the problems of long reaction time, complicated reaction process, complicated preparation process, etc., and achieves no toxic by-product formation and tumor inhibition. The effect of high rate and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Weigh 1.0 gram of small-molecule Caragana rhizobium exopolysaccharide (7.216kD) into the flask, then add 100 mL of nitric acid solution with a mass concentration of 1% to dissolve it, and stir at room temperature for 12 hours; then weigh 0.5 gram of Selenic acid and 0.6 g of barium chloride were added to the flask, stirred and heated at 60°C for 6 hours;

[0017] 2) Add 2.88 mL of 1 mol / L sulfuric acid dropwise to the above reaction solution, and centrifuge at 6000 rpm for 15 minutes to remove the precipitate;

[0018] 3) Use sodium hydroxide to adjust the pH value of the supernatant to 7, put it into a dialysis bag with a molecular weight cut-off of 3000Da, first dialyze with tap water for 60 hours, then dialyze with distilled water for 24 hours, until the dialysis is detected with 0.002 mg / mL ascorbic acid solution until the liquid outside the bag no longer turns red;

[0019] 4) Concentrate the dialysate under reduced pressure at 60°C and 0.08Mpa to 1 / 2 of the or...

Embodiment 2

[0021] 1) Weigh 1.0 gram of small-molecule Caragana rhizobium exopolysaccharide (10.352kD) into the flask, then add 100 mL of nitric acid solution with a mass concentration of 1% to dissolve it, and stir at room temperature for 8 hours; Selenic acid and 0.9 g of barium chloride were added into the flask, stirred and heated at 70°C for 7 hours;

[0022] 2) Add 4.32 mL of 1 mol / L sulfuric acid dropwise to the above reaction solution, and centrifuge at 6000 rpm for 20 minutes to remove the precipitate;

[0023] 3) Use sodium hydroxide to adjust the pH value of the supernatant to 7, put it into a dialysis bag with a molecular weight cut-off of 3000Da, first dialyze with tap water for 48 hours, then dialyze with distilled water for 24 hours, until the dialysis is detected with 0.002 mg / mL ascorbic acid solution until the liquid outside the bag no longer turns red;

[0024] 4) Concentrate the dialysate under reduced pressure at 60°C and 0.08Mpa to 1 / 2 of the original volume, add 20...

Embodiment 3

[0026] 1) Weigh 1.0 gram of small molecule Caragana rhizobium exopolysaccharide (30.641kD) and add it to the flask, then add 100 mL of nitric acid solution with a mass concentration of 2% to dissolve it, and stir at room temperature for 10 hours; Selenic acid and 1.2 grams of barium chloride were added to the flask, stirred and heated at 80°C for 6 hours;

[0027] 2) Add 5.76 mL of 1 mol / L sulfuric acid dropwise to the above reaction solution, and centrifuge at 5000 rpm for 15 minutes to remove the precipitate;

[0028] 3) Use sodium hydroxide to adjust the pH value of the supernatant to 7, put it into a dialysis bag with a molecular weight cut-off of 5000Da, first dialyze with tap water for 72 hours, then dialyze with distilled water for 36 hours, until the dialysis is detected with 0.001 mg / mL ascorbic acid solution until the liquid outside the bag no longer turns red;

[0029] 4) Concentrate the dialysate under reduced pressure at 60°C and 0.08Mpa to 1 / 2 of the original vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com