Supermolecular hydrogel and preparation method and application thereof

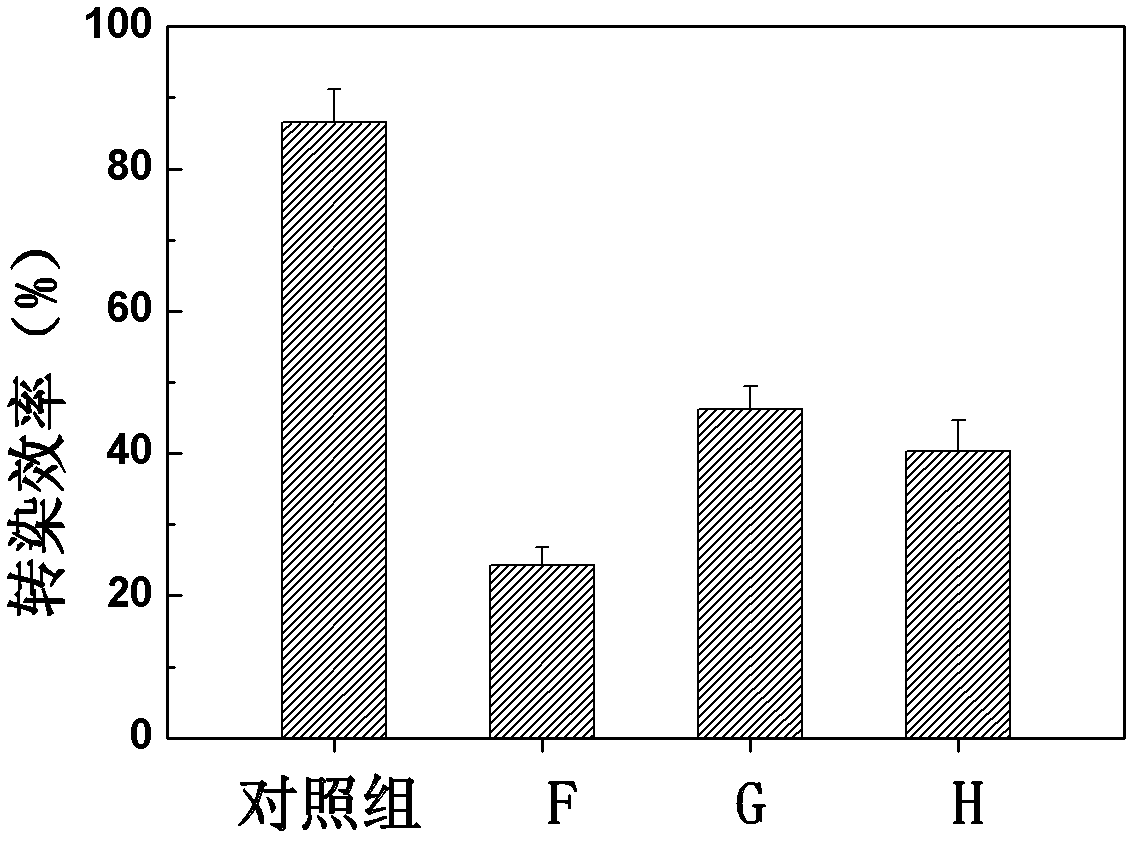

A technology of supramolecular hydrogel and weight-average molecular weight, which is applied in medical preparations of non-active ingredients, non-effective ingredients of polymer compounds, pharmaceutical formulations, etc., can solve the problems of little practical application value, low gene transfection efficiency, The material design is cumbersome and other problems, and the preparation method is convenient and fast, avoiding the influence of nucleic acid activity, and the concentration and temperature requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

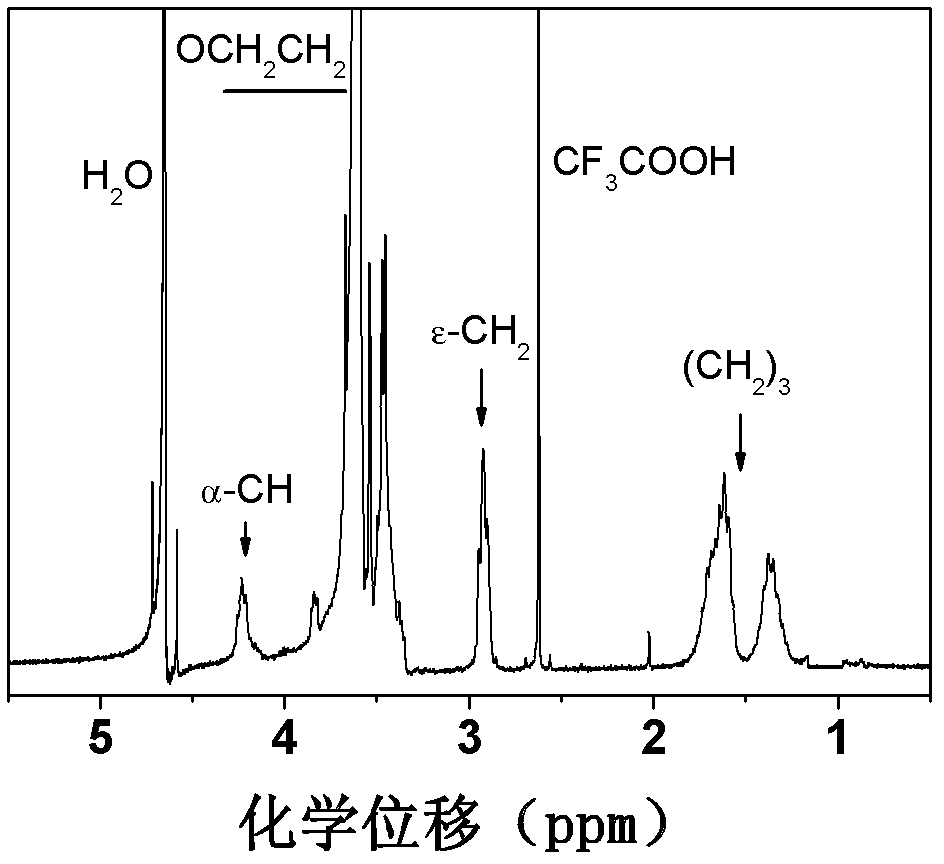

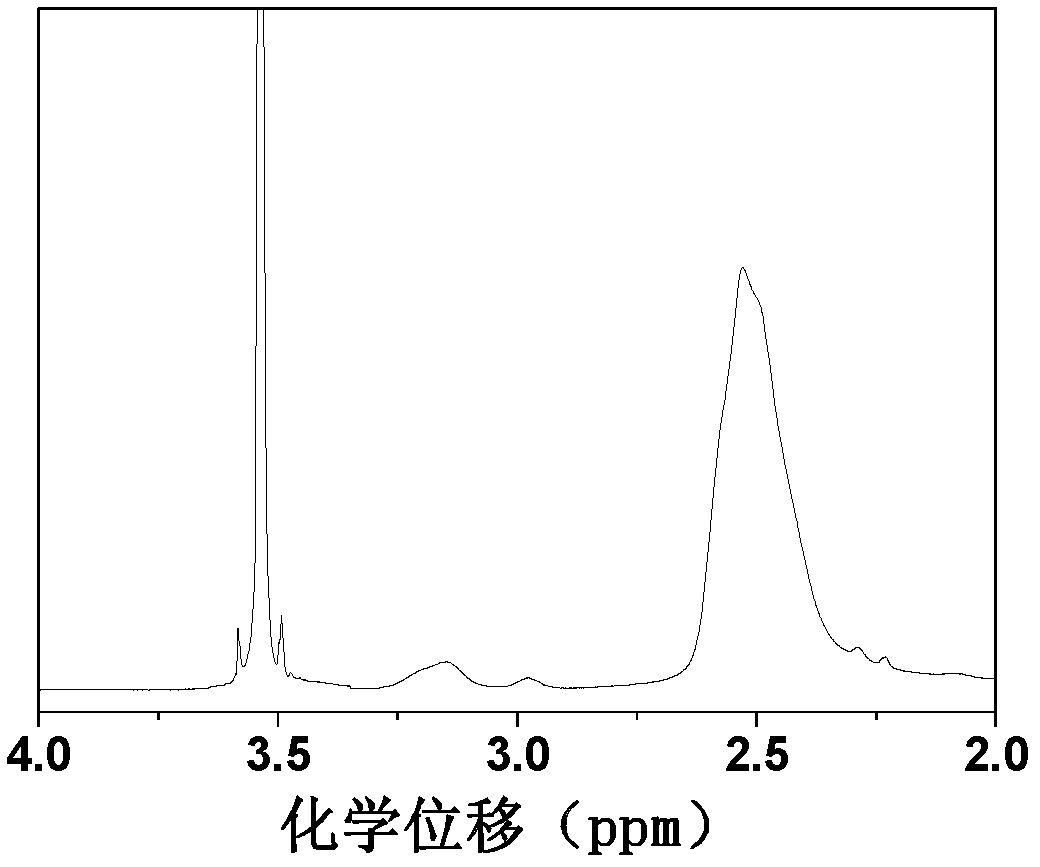

Embodiment 1

[0045] 1. Drying of polyethylene glycol: The polyethylene glycol is vacuum dried at 80°C for 24 hours.

[0046] 2. Drying of dichloromethane and pyridine: add calcium hydride powder to dichloromethane or pyridine solution (add 1-2 grams of calcium hydride per 500ml solution), stir at room temperature for 24 hours and then distill.

[0047] 3. Synthesis of polyethylene glycol-p-toluate:

[0048] Dissolve 15 grams of dry polyethylene glycol (weight average molecular weight 5000) in 100 ml of a mixed solution of dichloromethane and pyridine. The volume ratio of dichloromethane to pyridine is 2:1; then add the mole number of polyethylene glycol. P-toluene sulfonyl chloride twice the alcohol, reacted for 48 hours at 30 degrees Celsius in the dark; after the reaction, the reaction solution was extracted with an equal volume of 3mol / L hydrogen chloride solution, and the organic layer was neutralized with 3 grams of sodium bicarbonate , Filter; then at 60 degrees Celsius to remove the methy...

Embodiment 2

[0056] 1. Drying of polyethylene glycol: The polyethylene glycol is vacuum dried at 80°C for 24 hours.

[0057] 2. Drying of dichloromethane and pyridine: add calcium hydride powder to dichloromethane or pyridine solution (add 1-2 grams of calcium hydride per 500ml solution), stir at room temperature for 24 hours and then distill.

[0058] 3. Synthesis of polyethylene glycol-p-toluenesulfonate:

[0059] Dissolve 15g of dry polyethylene glycol (weight average molecular weight 2000) in 100ml of a mixed solution of dichloromethane and pyridine. The volume ratio of dichloromethane to pyridine is 2:1; then add the moles of polyethylene glycol 2 Toluene sulfonyl chloride was reacted for 36 hours at 25°C in the dark; after the reaction, the reaction solution was extracted with an equal volume of 3mol / L hydrogen chloride solution, and the organic layer was neutralized and filtered with 4 grams of sodium bicarbonate ; Then at 50 ℃ conditions of rotary evaporation to remove the dichloromethan...

Embodiment 3

[0067] 1. Drying of polyethylene glycol: The polyethylene glycol is vacuum dried at 80°C for 24 hours.

[0068] 2. Drying of dichloromethane and pyridine: add calcium hydride powder to dichloromethane or pyridine solution (add 1-2 grams of calcium hydride per 500ml solution), stir at room temperature for 24 hours and then distill.

[0069] 3. Synthesis of polyethylene glycol-p-toluate:

[0070] Dissolve 15g of dry polyethylene glycol (weight average molecular weight 10000) in 100ml of a mixed solution of dichloromethane and pyridine, the volume ratio of dichloromethane to pyridine is 2:1; then add the mole number of polyethylene glycol 2 Toluene sulfonyl chloride was reacted for 48 hours at 25°C in the dark; after the reaction, the reaction solution was extracted with an equal volume of 3mol / L hydrogen chloride solution, and the organic layer was neutralized and filtered with 3g sodium bicarbonate; Then, the dichloromethane is removed by rotary evaporation at 60° C. to obtain polyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com