Gas chromatography valve path system for analyzing multiple high-purity fluorine-containing electronic gases and using method of system

An electronic gas and gas chromatography technology, applied in the field of multi-dimensional gas chromatography valve circuit system, can solve the problems of single gas circuit, cumbersome operation, low analysis efficiency, etc., to reduce corrosion and influence, avoid pollution and damage, and reduce residual time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

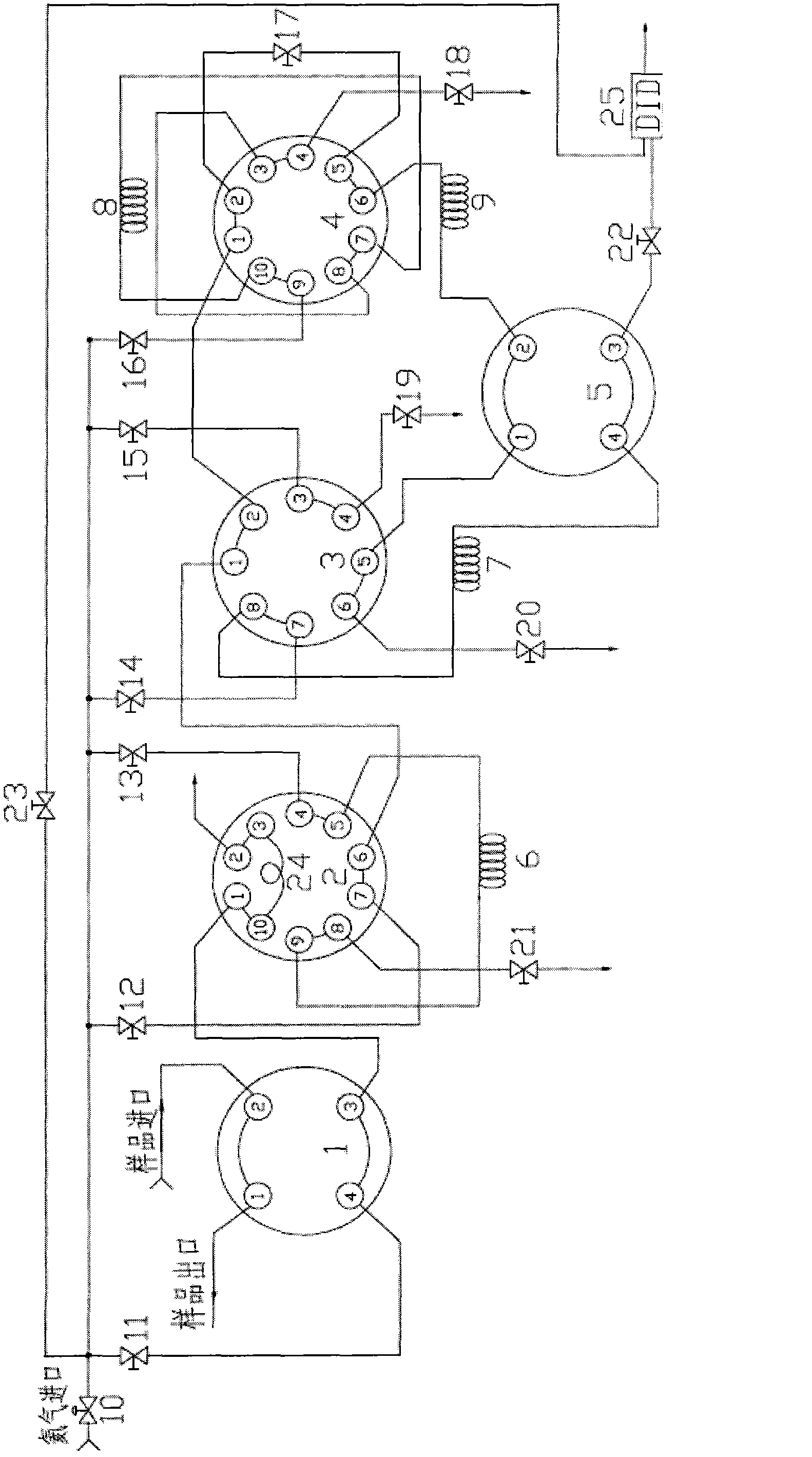

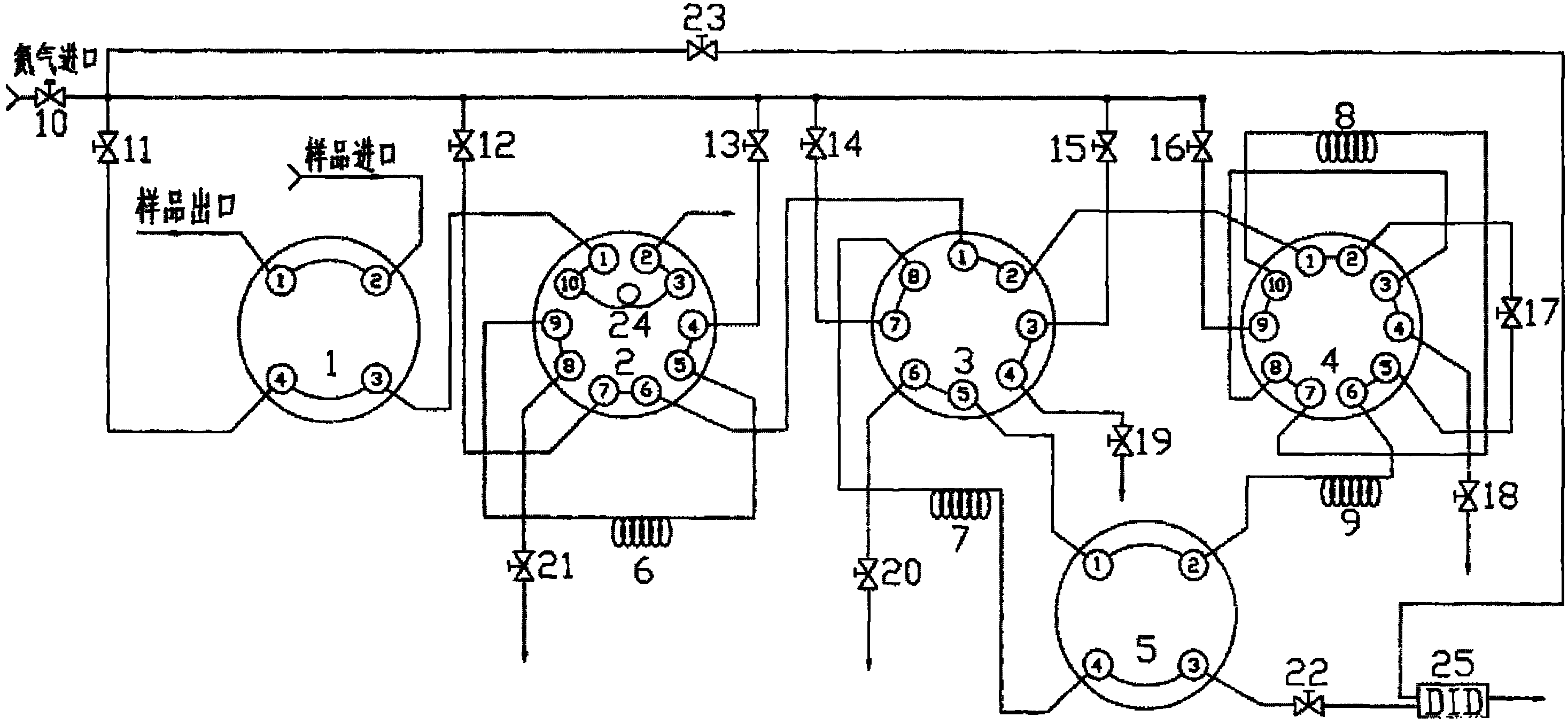

[0051] Example 1: Separation and detection of gas-phase impurities in high-purity sulfur hexafluoride

[0052] Gas-phase impurities in sulfur hexafluoride with a purity of more than 99.999% mainly include: nitrogen (N 2 ), oxygen (O 2 ), carbon monoxide (CO), carbon dioxide (CO 2 ), methane (CH 4 ), carbon tetrafluoride (CF 4 ).

[0053] The pre-separation chromatographic column 6 is a silica gel chromatographic column with a length of 2 meters.

[0054] The first analytical chromatographic column 7 is a 5A molecular sieve chromatographic column with a length of 2 meters.

[0055] The second analytical chromatographic column 8 is a Hayesep Q chromatographic column with a length of 3 meters.

[0056] The third analytical chromatographic column 9 is a Hayesep Q chromatographic column with a length of 6 meters.

[0057] 1. Attached figure 1 In this state, the quantitative loop 24 is purged with the carrier gas, and the sulfur hexafluoride sample passes through the first f...

Embodiment 2

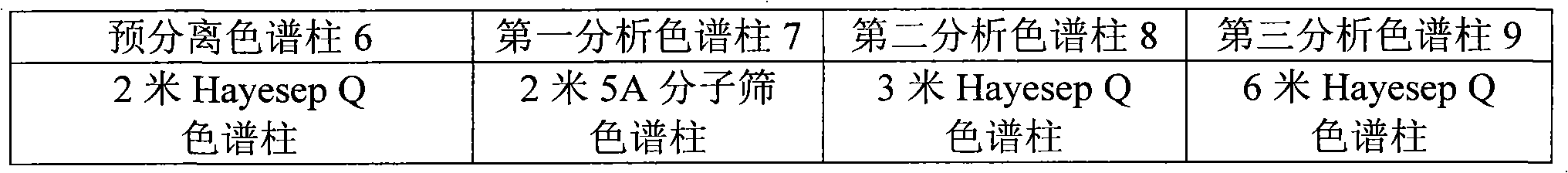

[0065] Example 2: Separation and detection of gas phase impurities in high-purity nitrogen trifluoride

[0066] Gas-phase impurities in nitrogen trifluoride with a purity of more than 99.99% mainly include: nitrogen (N 2 ), oxygen (O 2 ), carbon monoxide (CO), carbon dioxide (CO 2 ), carbon tetrafluoride (CF 4 ), nitrous oxide (N 2 O), sulfur hexafluoride (SF 6 ).

[0067] The pre-separation chromatographic column 6 is a Hayesep Q chromatographic column with a length of 2 meters.

[0068] The first analytical chromatographic column 7 is a 5A molecular sieve chromatographic column with a length of 2 meters.

[0069] The second analytical chromatographic column 8 is a Hayesep Q chromatographic column with a length of 3 meters.

[0070] The third analytical chromatographic column 9 is a Hayesep Q chromatographic column with a length of 6 meters.

[0071] 1. Attached figure 1 In this state, the quantitative loop 24 is purged with carrier gas, and the nitrogen trifluoride ...

Embodiment 3

[0079] Example 3: Separation and detection of gas phase impurities in high-purity tungsten hexafluoride

[0080] Gas-phase impurities in tungsten hexafluoride with a purity of more than 99.999% mainly include: nitrogen (N 2 ), oxygen (O 2 ), carbon monoxide (CO), carbon dioxide (CO 2 ), carbon tetrafluoride (CF 4 ), sulfur hexafluoride (SF 6 ).

[0081] The pre-separation chromatographic column 6 is a fluorine oil chromatographic column with a length of 4 meters.

[0082] The first analytical chromatographic column 7 is a 5A molecular sieve chromatographic column with a length of 2 meters.

[0083] The second analytical chromatographic column 8 is a Hayesep Q chromatographic column with a length of 3 meters.

[0084] The third analytical chromatographic column 9 is a Hayesep Q chromatographic column with a length of 6 meters.

[0085] 1. Attached figure 1 In this state, the quantitative loop 24 is purged with carrier gas, and the tungsten hexafluoride sample is collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com