Lithium formate metal complex, production method thereof and organic electroluminescence device

The invention relates to a metal complex and a production method technology, which are applied in the field of organic electroluminescent devices, and can solve the problems of affecting the electron injection capability of an electron injection layer, improving the accuracy requirements of evaporation equipment, and reducing the comprehensive performance of light-emitting devices, so as to improve the electron injection capability. ability, improving the luminous quantum efficiency, and the effect of improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

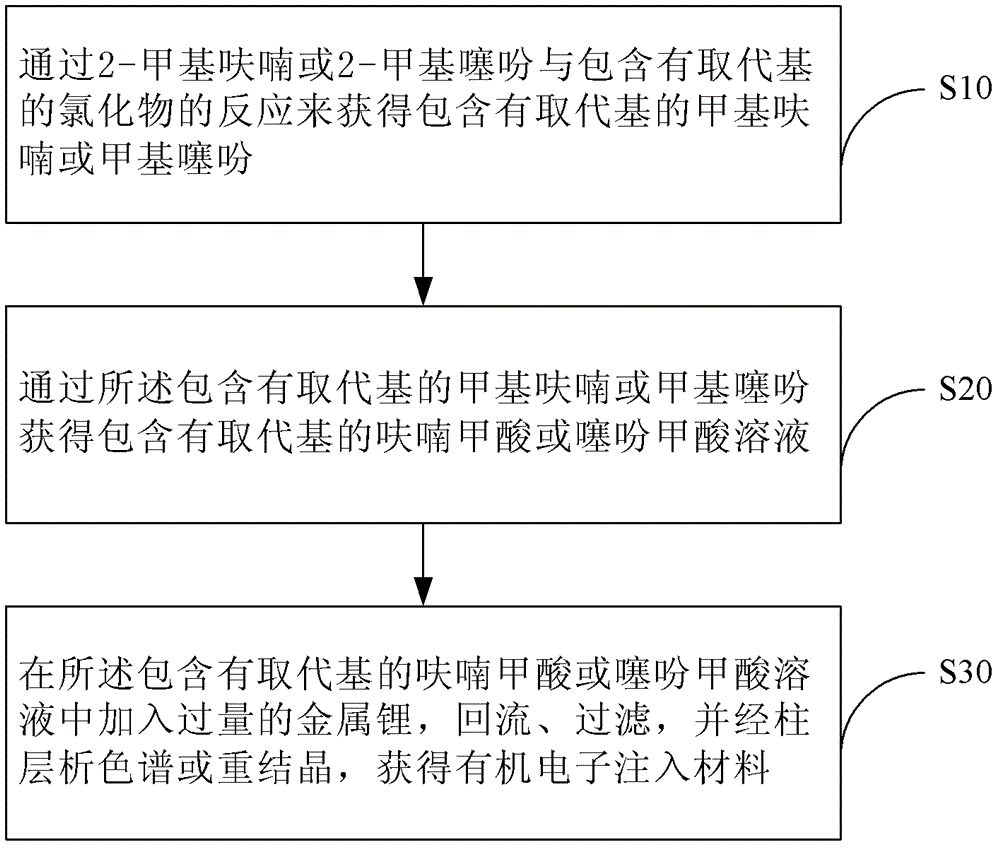

Method used

Image

Examples

Embodiment 1

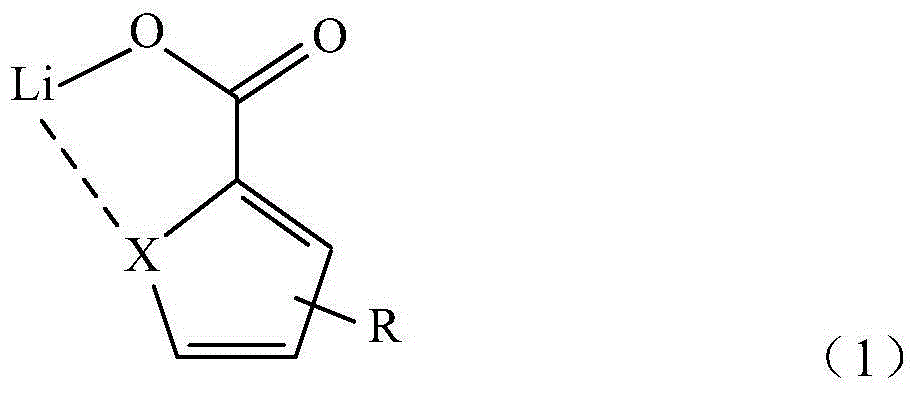

[0097] Lithium metal complex of 4-methylfuroate

[0098] a. Dissolve 1 mole of 2-methylfuran in nitrobenzene organic solvent, ice bath, slowly add 1 mole of anhydrous AlCl under stirring 3 and 1 mole of CH 3 Cl.

[0099] b. Heat the nitrobenzene organic solvent to 50°C to make 2-methylfuran and CH 3 Cl was reacted for 10 hours.

[0100] c. Add hydrochloric acid and ice-water mixture to the reacted nitrobenzene organic solvent to make AlCl 3 The intermediate product generated in the catalytic process is acidolytically reduced to AlCl 3 .

[0101] d. Distillation under reduced pressure to obtain 2,4-dimethylfuran.

[0102] e. Dissolve the 2,4-dimethylfuran obtained in step d in an aqueous solution of ethanol, and then add 0.01 moles of KMnO 4 , so that KMnO 4 Reaction with 2,4-dimethylfuran in ethanol for 1 hour gives 4-methylfurancarboxylic acid.

[0103] f. Add excess metal lithium in 4-methylfuranic acid solution, reflux for 3 hours under anhydrous and oxygen-free co...

Embodiment 2

[0106] Lithium metal complex of 3-cyanothiophenecarboxylate

[0107] a. Dissolve 1 mole of 2-methylthiophene in tetrahydrofuran organic solvent, ice bath, slowly add 1.1 moles of anhydrous AlCl under stirring 3 and 1.1 moles of CNCl.

[0108] b. Heat the tetrahydrofuran organic solvent to 60° C. to react 2-methylthiophene with CNCl for 11 hours.

[0109] c. Add hydrochloric acid and ice-water mixture to the tetrahydrofuran organic solvent that reacts, make AlCl 3 The intermediate product generated in the catalytic process is acidolytically reduced to AlCl 3 .

[0110] d. Distillation under reduced pressure to obtain 2-methyl-3-cyanothiophene.

[0111] e. Dissolve the 2-methyl-3-cyanothiophene obtained in step d in an aqueous solution of ethanol, and then add 0.011 moles of KMnO 4 , so that KMnO 4 React with 2-methyl-3-cyanothiophene in ethanol for 1.5 hours to obtain 3-cyanothiophenecarboxylic acid.

[0112] f. Add excess metal lithium in 3-cyanothiophenecarboxylic acid...

Embodiment 3

[0115] Lithium metal complex of 4-trifluoromethylfuroate

[0116] a. Dissolve 1 mole of 2-methylfuran in dichloromethane organic solvent, ice bath, slowly add 1.2 moles of anhydrous AlCl under stirring 3 and 1.2 molar CF 3 Cl.

[0117] b. Heat the dichloromethane organic solvent to 70°C to make 2-methylfuran and CF 3 Cl was reacted for 12 hours.

[0118] c. Add hydrochloric acid and ice-water mixture to the dichloromethane organic solvent that reacts, so that AlCl 3 The intermediate product generated in the catalytic process is acidolytically reduced to AlCl 3 .

[0119] d. Distillation under reduced pressure to obtain 2-methyl-4-trifluoromethylfuran.

[0120] e. Dissolve the 2-methyl-4-trifluoromethylfuran obtained in step d in an aqueous solution of ethanol, and then add 0.012 moles of KMnO 4 , so that KMnO 4 Reaction with 2-methyl-4-trifluoromethylfuran in ethanol for 3 hours gave 4-trifluoromethylfurancarboxylic acid.

[0121] f. Add excess metal lithium to the 4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com