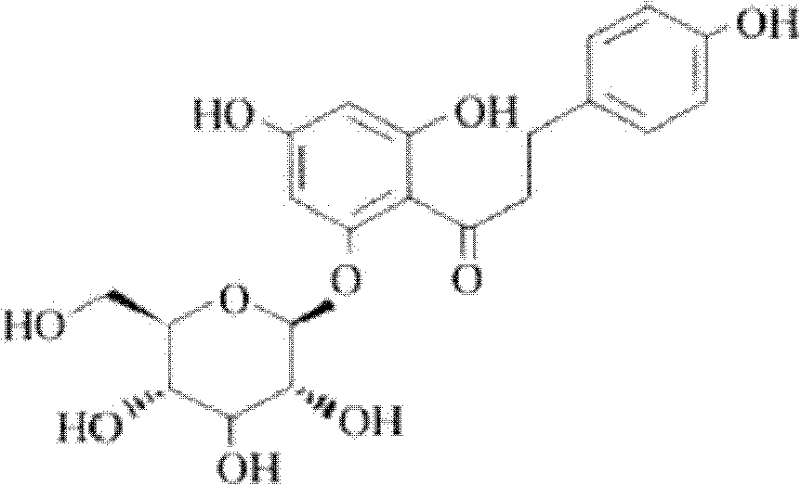

Method for purifying phlorizin from apple velamen

A technology of phlorizin and root bark is applied in the field of extraction and separation of dihydrochalcones, can solve problems such as being unsuitable for industrialized production, relatively expensive, etc., and achieves high product yield, short process cycle and less environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) extraction

[0049] The raw material of apple root bark is crushed to obtain a crushed product, and the crushed product is extracted three times with purified water of 4 times the mass of the raw material of apple root bark, and the extract is collected; wherein the purified water used is added with 0.5% of its mass Sodium hydroxide, the extraction temperature is 50°C, and the extraction time is 3 hours;

[0050] (2) concentrated

[0051] Concentrating the obtained extract to obtain an extract, the specific gravity of the extract is 0.95, and filtering to obtain a filtrate;

[0052] (3) Acid adjustment

[0053] The resulting filtrate was adjusted to pH=5 with acetic acid, left to stand, and centrifuged to obtain a precipitate and a supernatant, the precipitate being the crude phlorizin;

[0054] (4) Recrystallization

[0055] Dissolve the obtained crude phloridzin in 5 times the amount of pure water, add activated carbon with 5% weight of the crude phloridzin to...

Embodiment 2

[0058] (1) extraction

[0059]The raw material of apple root bark is crushed to obtain a pulverized product, and the pulverized product is extracted twice with purified water of 8 times the mass of the raw material of apple root bark, and the extract is collected; wherein the purified water used is added with 1% of its mass Sodium carbonate, the extraction temperature is 55°C, and the extraction time is 2 hours;

[0060] (2) concentrated

[0061] Concentrating the obtained extract to obtain an extract, the specific gravity of the extract is 1.03, and filtering to obtain a filtrate;

[0062] (3) Acid adjustment

[0063] The resulting filtrate was adjusted to pH=4 with hydrochloric acid, left to stand, and centrifuged to obtain a precipitate and a supernatant, the precipitate being the crude phlorizin;

[0064] (4) Recrystallization

[0065] Dissolve the obtained crude phlorizin in 6 times the amount of pure water, add a decolorizing agent (activated carbon: activated clay =...

Embodiment 3

[0068] The raw material of apple root bark is crushed to obtain a pulverized product, and the pulverized product is extracted twice with purified water of 9 times the mass of the raw material of apple root bark, and the extract is collected; wherein the purified water used is added with 1.8% of its mass Sodium bicarbonate, the extraction temperature is 65°C, and the extraction time is 2 hours;

[0069] (2) concentrated

[0070] Concentrating the obtained extract to obtain an extract, the specific gravity of the extract is 1.08, and filtering to obtain a filtrate;

[0071] (3) Acid adjustment

[0072] The resulting filtrate was adjusted to pH=2.5 with sulfuric acid, left to stand, and centrifuged to obtain a precipitate and a supernatant, the precipitate being the crude phlorizin;

[0073] (4) Recrystallization

[0074] Dissolve the obtained crude phloridizin in 9 times the amount of pure water, add diatomaceous earth with a weight of 16% of the crude product of phloridizin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com