Method for improving doping uniformity among silicon carbide multilayer structure epitaxial material batches

A technology of epitaxial materials and multi-layer structures, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as strong background memory effect, reduced production capacity, and lattice loss, so as to reduce background memory effect and improve repetition performance, improve precise and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

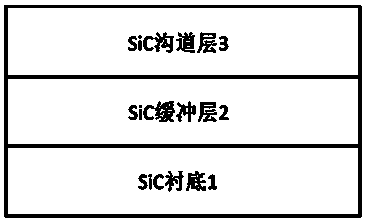

[0026] The provided method for epitaxially growing a 600V Schottky diode structure epitaxial material on a (0001) silicon surface silicon carbide substrate with an 8° bias to the direction includes the following steps:

[0027] 1) Select the (0001) silicon surface 4H-SiC conductive substrate for epitaxial growth with an angle of 8° to the direction, and place the substrate on a graphite base coated with tantalum carbide;

[0028] 2) The system is heated up to 1400°C, and the pressure is set to 100mbar, and the substrate surface is treated online under the atmosphere of hydrogen (flow 80L / min), argon (flow 3L / min) and propane (flow 10ml / min) to remove the surface damage and contamination, the treatment time is the time required for the temperature to rise from 1400°C to the actual growth temperature of 1570°C;

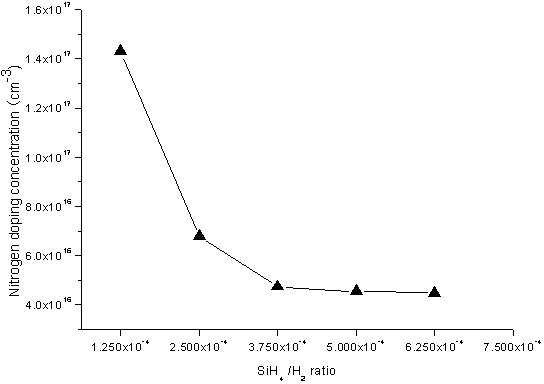

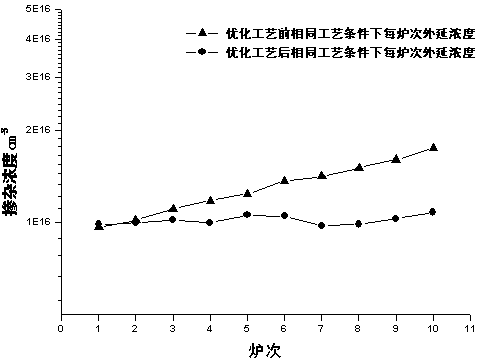

[0029] 3) The temperature is stabilized at 1570°C, the set pressure is 100mbar, the flow rates of silane and propane are 10ml / min and 3.5ml / min respectively, the carb...

Embodiment 2

[0037] The provided method for epitaxially growing 1200V JFET epitaxial materials on a (0001) silicon surface silicon carbide substrate with an 8° bias to the direction includes the following steps:

[0038] 1) Select the (0001) silicon surface 4H-SiC conductive substrate for epitaxial growth with an angle of 8° to the direction, and place the substrate on a graphite base coated with tantalum carbide;

[0039] 2) The system is heated up to 1400°C, and the pressure is set to 100mbar, and the substrate surface is treated online under the atmosphere of hydrogen (flow 80L / min), argon (flow 3L / min) and propane (flow 10ml / min) to remove the surface damage and contamination, the treatment time is the time required for the temperature to rise from 1400°C to the actual growth temperature of 1570°C;

[0040] 3) The temperature is stabilized at 1570°C, the set pressure is 100mbar, the flow rates of silane and propane are 20ml / min and 10ml / min respectively, the carbon-silicon ratio at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com