Non-oxidative magnetic multi-wall carbon nanotube and preparation method as well as application thereof

A multi-walled carbon nanotube, non-oxidizing technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of limited application, difficult separation of carbon nanotubes, etc., reaching equilibrium time Short, magnetically stable, method-simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

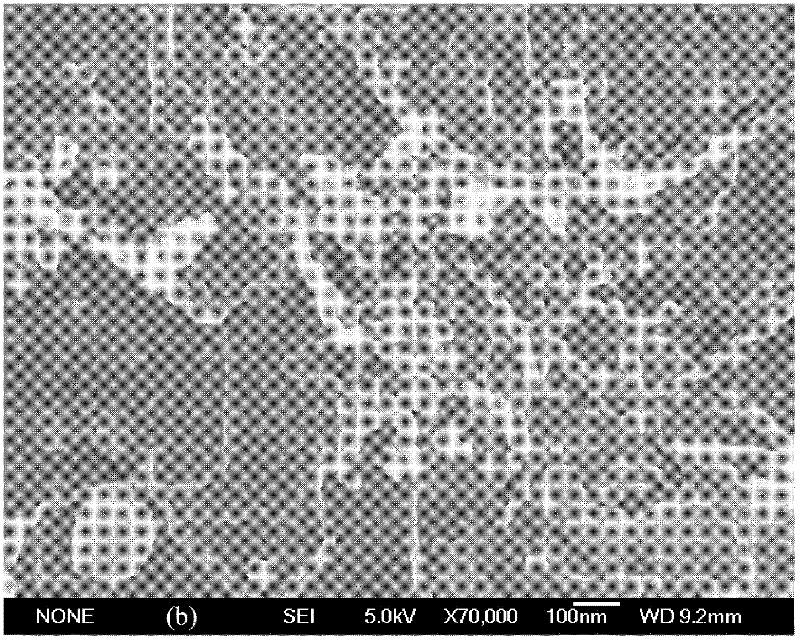

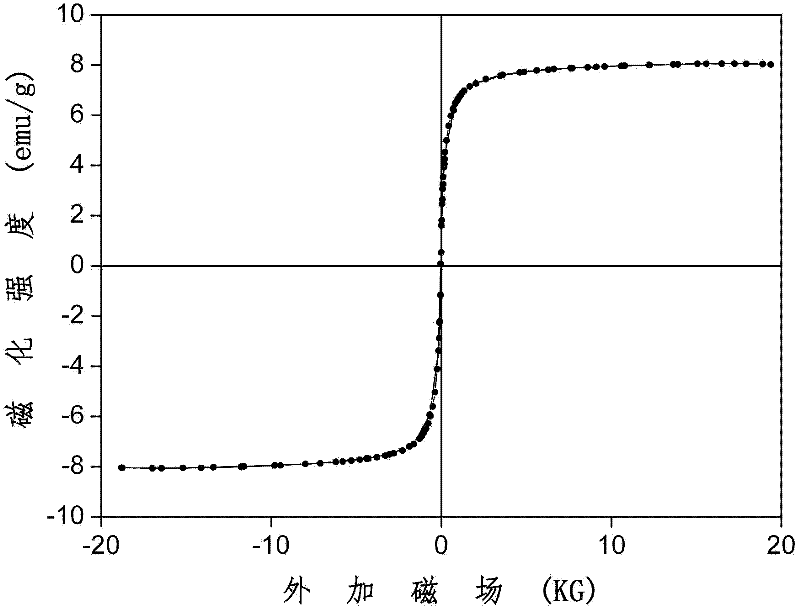

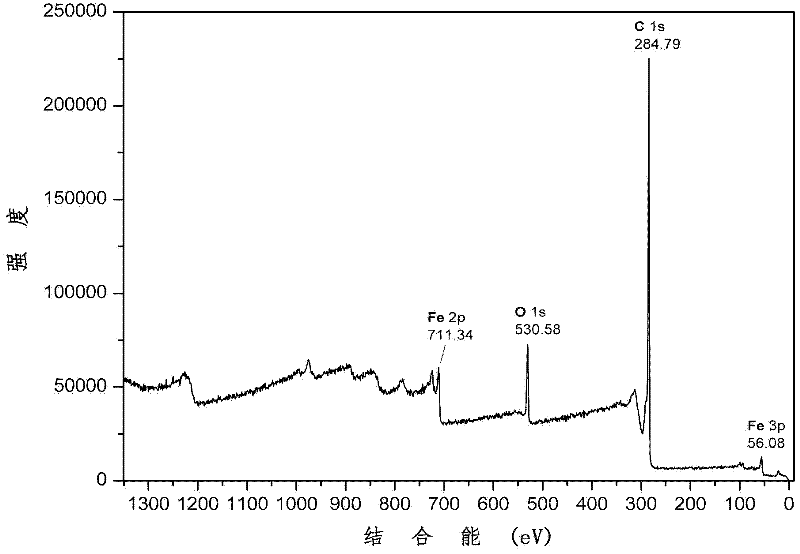

[0034] a kind of like figure 1 The shown non-oxidized magnetic multi-walled carbon nanotubes, the non-oxidized magnetic multi-walled carbon nanotubes are based on cross-linked non-oxidized multi-walled carbon nanotubes, and the substrate is loaded with magnetic iron oxide particles. In this embodiment The specific surface area of non-oxidized magnetic multi-walled carbon nanotubes is 138.66m 2 / g, its saturation magnetization is 8.06emu / g.

[0035] The preparation method of the non-oxidized magnetic multi-walled carbon nanotubes of the present embodiment comprises the following steps:

[0036] (1) Under the protection of nitrogen, the non-oxidized multi-walled carbon nanotubes are added to the mixed solution of ferric ammonium sulfate and ferrous ammonium sulfate to obtain a suspension of non-oxidized multi-walled carbon nanotubes with a concentration of 5g / L, ferric ammonium sulfate The mixed solution with ferrous ammonium sulfate is mainly composed of (NH 4 ) 2 Fe(SO 4...

Embodiment 2

[0041] A method for removing pollutants with the non-oxidized magnetic multi-walled carbon nanotubes obtained in Example 1, comprising the following steps:

[0042] 10mg of non-oxidized magnetic multi-walled carbon nanotubes prepared in Example 1 were added to 2 groups of 50mL atrazine solutions or Cu 2+ In the solution, the initial concentration of atrazine in the atrazine solution is 5mg / L, Cu 2+ Cu in solution 2+ The initial concentration was 30 mg / L, and the pH value of each group of mixed solutions was adjusted to 6.0. Among the two groups of solutions for each pollutant, one group was not treated with ultrasonic treatment, and the other group was treated with ultrasonic treatment for 1 min. Place in a constant temperature oscillator in a water bath and vibrate for 24 hours at a temperature of 25°C and a rotational speed of 150 rpm to carry out an adsorption reaction for 24 hours, then use a magnet to separate the adsorbent from the solution, and use high performance liq...

Embodiment 3

[0047] Example 3: Using non-oxidized magnetic multi-walled carbon nanotubes to remove atrazine from water.

[0048] A method for removing atrazine in water bodies with different pH values by utilizing the non-oxidized magnetic multi-walled carbon nanotubes obtained in Example 1, comprising the following steps:

[0049] 10 mg of non-oxidized magnetic multi-walled carbon nanotubes prepared in Example 1 were added to 7 groups of 50 mL atrazine solutions, the initial concentration of atrazine was 5 mg / L, and the pH value of each group of mixed solutions was adjusted respectively 3.0, 4.0, 5.0, 6.0, 7.0, 8.0 and 9.0, after ultrasonic treatment for 1min, place in a water bath constant temperature oscillator at a constant temperature of 25°C, shake at a speed of 150rpm for adsorption reaction for 24h, and then use a magnet to separate the adsorbent from the solution Come out, and measure the residual atrazine concentration in the solution with high performance liquid chromatography...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com