In-ga-o oxide sintered body, target, oxide semiconductor thin film, and manufacturing methods therefor

A technology of oxide semiconductor and sintered body, which is applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve problems such as insufficient research, and achieve the effect of suppressing abnormal discharge and stable reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0131] Indium oxide powder with an average particle size of 0.98 μm and gallium oxide powder with an average particle size of 0.96 μm were weighed so that the atomic ratio Ga / (Ga+In) shown in Table 1 was obtained, finely pulverized and mixed uniformly, and added to the molding Granulation with a binder. Next, the raw material mixed powder was uniformly filled in a mold, and compression molding was performed at a press pressure of 140 MPa with a cold press. The molded body thus obtained was fired in a sintering furnace at the firing temperature and firing time shown in Table 1 to produce a sintered body.

[0132] The firing atmosphere was an oxygen atmosphere during the temperature rise, and otherwise in the air (atmosphere), and the firing was performed at a temperature rise rate of 1°C / min and a temperature fall rate of 15°C / min.

[0133] In addition, the average particle diameter of the raw material oxide powder used was measured with the laser diffraction particle size dis...

Embodiment 7

[0164] On a glass substrate and with a thermal oxide film (SiO 2 ) on silicon substrates, using the targets (Ga / (In+Ga)=0.114) obtained in Example 1, respectively, by DC magnetron sputtering, thin films with a film thickness of 50 nm were formed.

[0165] For the above sputtering, vacuum exhaust was performed until the back pressure reached 5 × 10 -4 Pa and then, while flowing 9 sccm of argon gas and 1 sccm of oxygen gas, the pressure was adjusted to 0.4 Pa, and the sputtering power was 100W at room temperature.

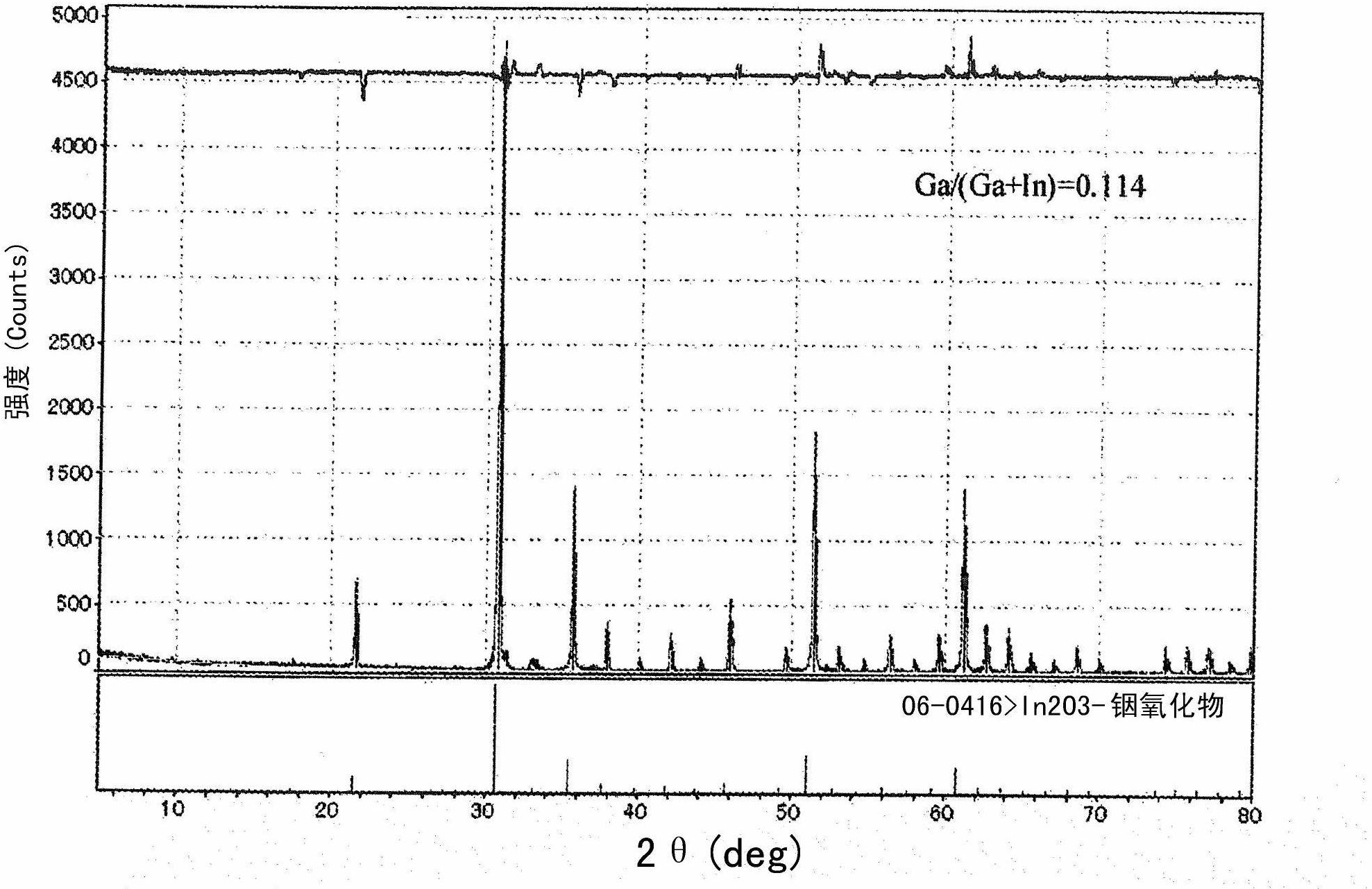

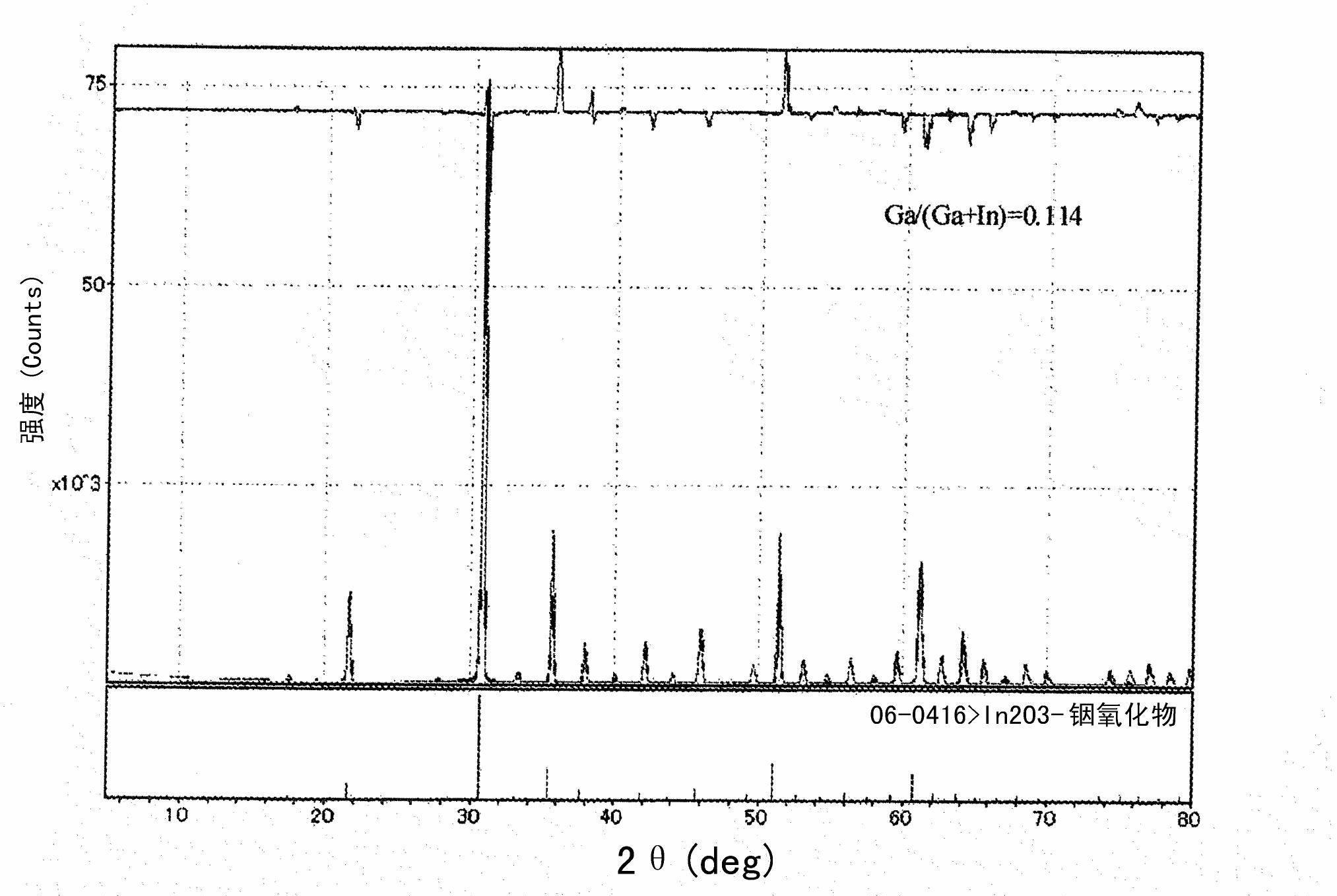

[0166] The crystal structure of the thin film formed on the glass substrate immediately after film formation was confirmed by XRD. As a result, no clear diffraction peak was observed, and it was confirmed that it was amorphous. The glass substrate on which the thin film was formed was put into a heating furnace heated to 300° C. in the air, and treated for 1 hour. As a result of XRD measurement of the thin film after the annealing treatment, only the peak of the b...

Embodiment 8

[0180] On a glass substrate and on a silicon substrate with a thermally oxidized film (SiO2) with a thickness of 100 nm, using the target (Ga / (In+Ga)=0.128) obtained in Example 3, respectively, by DC magnetron sputtering, respectively A thin film with a film thickness of 50 nm was formed.

[0181] For the above sputtering, vacuum exhaust was performed until the back pressure reached 5 × 10 -4 Pa and then, while flowing 8.5 sccm of argon gas and 1.5 sccm of oxygen gas, the pressure was adjusted to 0.4 Pa, and the sputtering power was 100W at room temperature.

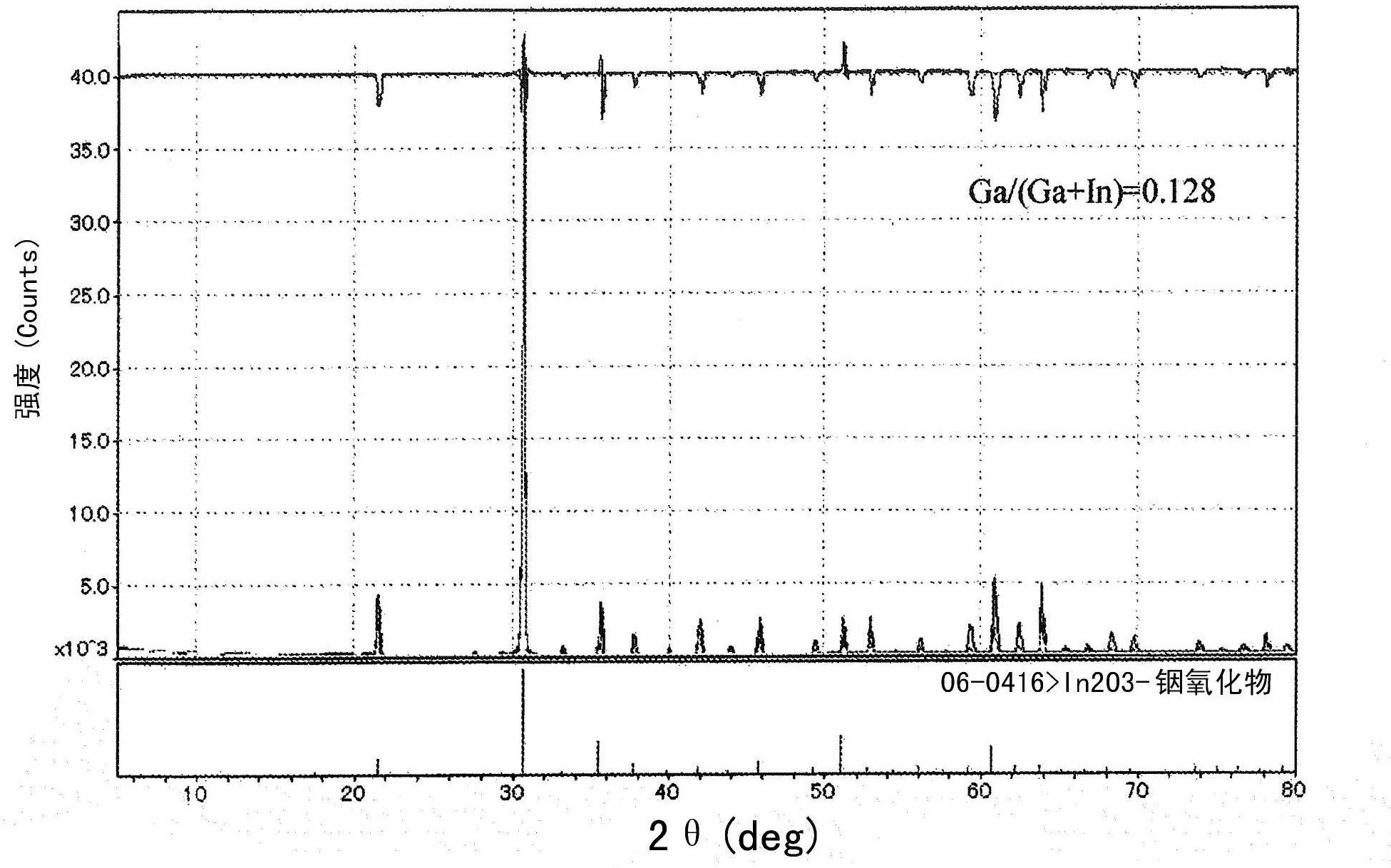

[0182] The crystal structure of the thin film formed on the glass substrate immediately after film formation was confirmed by XRD. As a result, no clear diffraction peak was observed, and it was confirmed that it was amorphous. The glass substrate on which the thin film was formed was put into a heating furnace heated to 300° C. in the air, and treated for 1 hour. As a result of XRD measurement of the thin film after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com