Method for preparing gallium nitride/zinc sulfide nano heterojunction by two-step method

A technology of zinc sulfide and heterojunction, applied in the direction of zinc sulfide, nanotechnology, nanotechnology, etc., can solve the problems of complex process, high cost and unsuitable for large-scale application in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

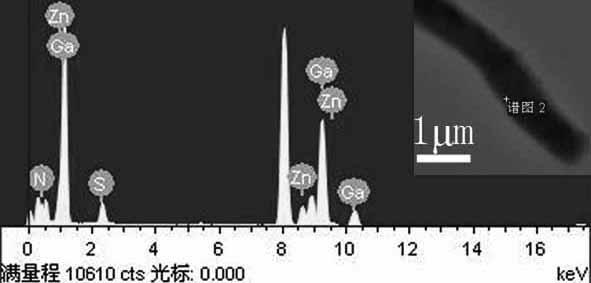

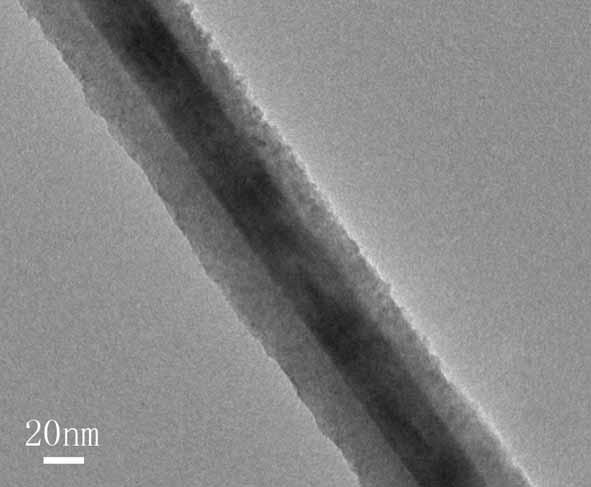

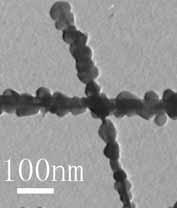

Embodiment 1

[0020] Place a ceramic boat containing a certain amount of gallium oxide (purity: 99.999% by mass) powder in the middle of the horizontal tube furnace, and place a gold-plated Si (100) sheet at a distance of 20 cm from the ceramic boat as a collection substrate for the product , sealed horizontal tube furnace and then evacuated to 2×10 -2 Pa, tube furnace heated to 1080 in Ar atmosphere o C, stop feeding Ar, feed 200sccm NH 3 gas reaction for 2 hours, and finally cooled to room temperature naturally under Ar atmosphere, and a pale yellow product was obtained on the collection substrate. Then carry out the second step, place the Si sheet deposited with the light yellow product on the sample holder of the vacuum thermal evaporation instrument, the deposition side is facing down, and the molybdenum boat with zinc sulfide (purity being 99.995% by mass) is directly facing below . The Si substrate and ZnS were separated by 1.5 cm. After installing the instrument, evacuate to 10 ...

Embodiment 2

[0023] Place a ceramic boat containing a certain amount of gallium oxide (purity: 99.999% by mass) powder in the middle of the horizontal tube furnace, and place a gold-plated Si (100) sheet at a distance of 20 cm from the ceramic boat as a collection substrate for the product , sealed horizontal tube furnace and then evacuated to 2×10 -3 Pa, tube furnace heated to 1080 in Ar atmosphere o C, stop feeding Ar, feed 200sccm NH 3 gas reaction for 2 hours, and finally cooled to room temperature naturally under Ar atmosphere, and a pale yellow product was obtained on the collection substrate. Then carry out the second step, place the Si sheet deposited with the light yellow product on the sample holder of the vacuum thermal evaporation instrument, the deposition side is facing down, and the molybdenum boat with zinc sulfide (purity being 99.995% by mass) is directly facing below . The Si substrate and ZnS were separated by 1.5 cm. After installing the instrument, evacuate to 10 ...

Embodiment 3

[0026] Place a ceramic boat containing a certain amount of gallium oxide (purity: 99.999% by mass) powder in the middle of the horizontal tube furnace, and place a gold-plated Si (100) sheet at a distance of 25 cm from the ceramic boat as a collection substrate for the product , sealed horizontal tube furnace and then evacuated to 2×10 -2 Pa, tube furnace heated to 1080 in Ar atmosphere o C, stop feeding Ar, feed 200sccm NH 3 gas reaction for 2 hours, and finally cooled to room temperature naturally under Ar atmosphere, and a pale yellow product was obtained on the collection substrate. Then carry out the second step, place the Si sheet deposited with the light yellow product on the sample holder of the vacuum thermal evaporation instrument, the deposition side is facing down, and the molybdenum boat with zinc sulfide (purity being 99.995% by mass) is directly facing below . The Si substrate and ZnS were separated by 1.5 cm. After installing the instrument, evacuate to 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com