Mycelium drought-resistant seed coating and preparation method thereof

A technology of mycelium and coating agent, applied in the directions of botanical equipment and methods, fungicides, biocides, etc., can solve the problems of seedling preservation and seedling cultivation, single function, etc. Yield, the effect of improving seedling vigor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

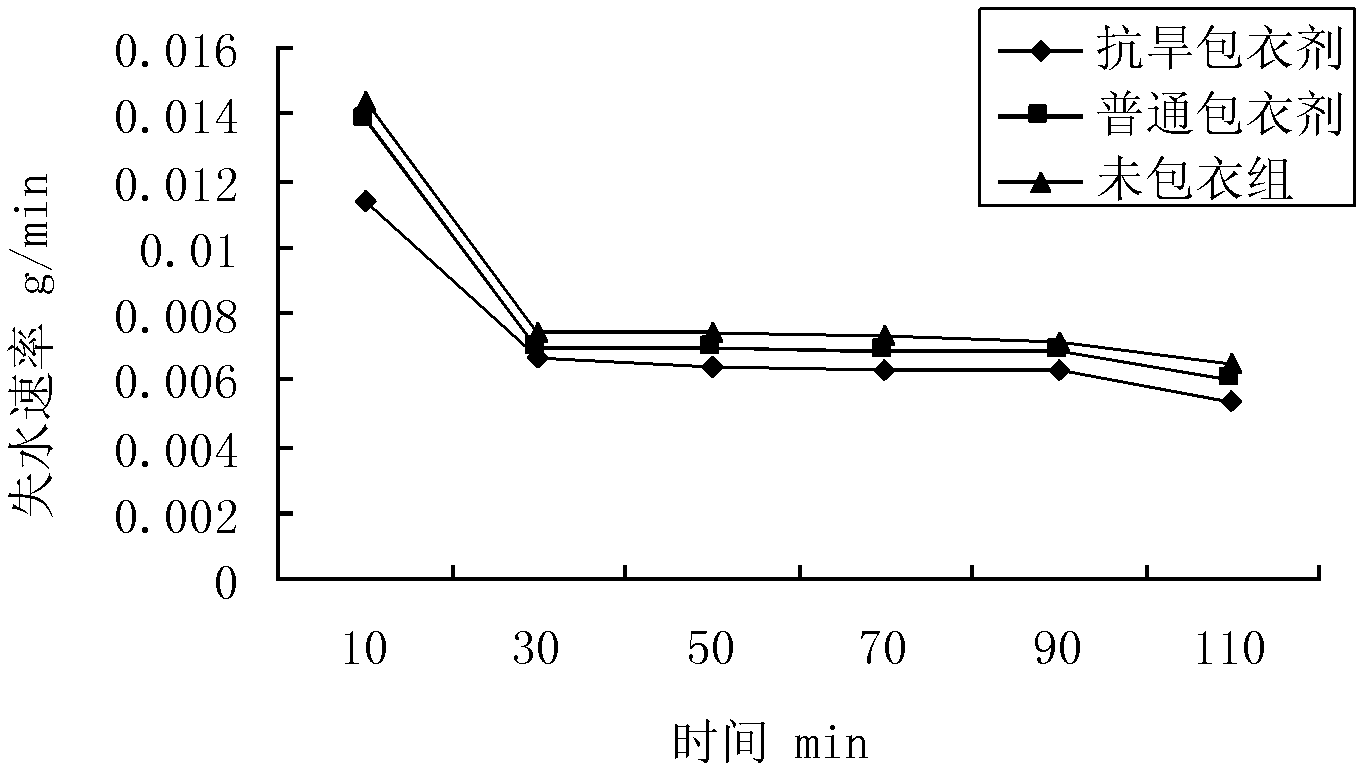

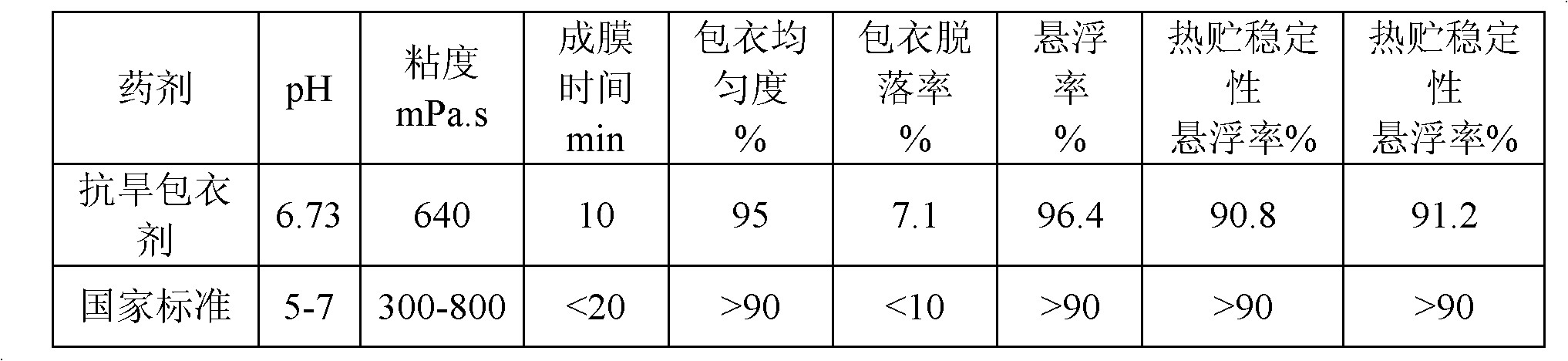

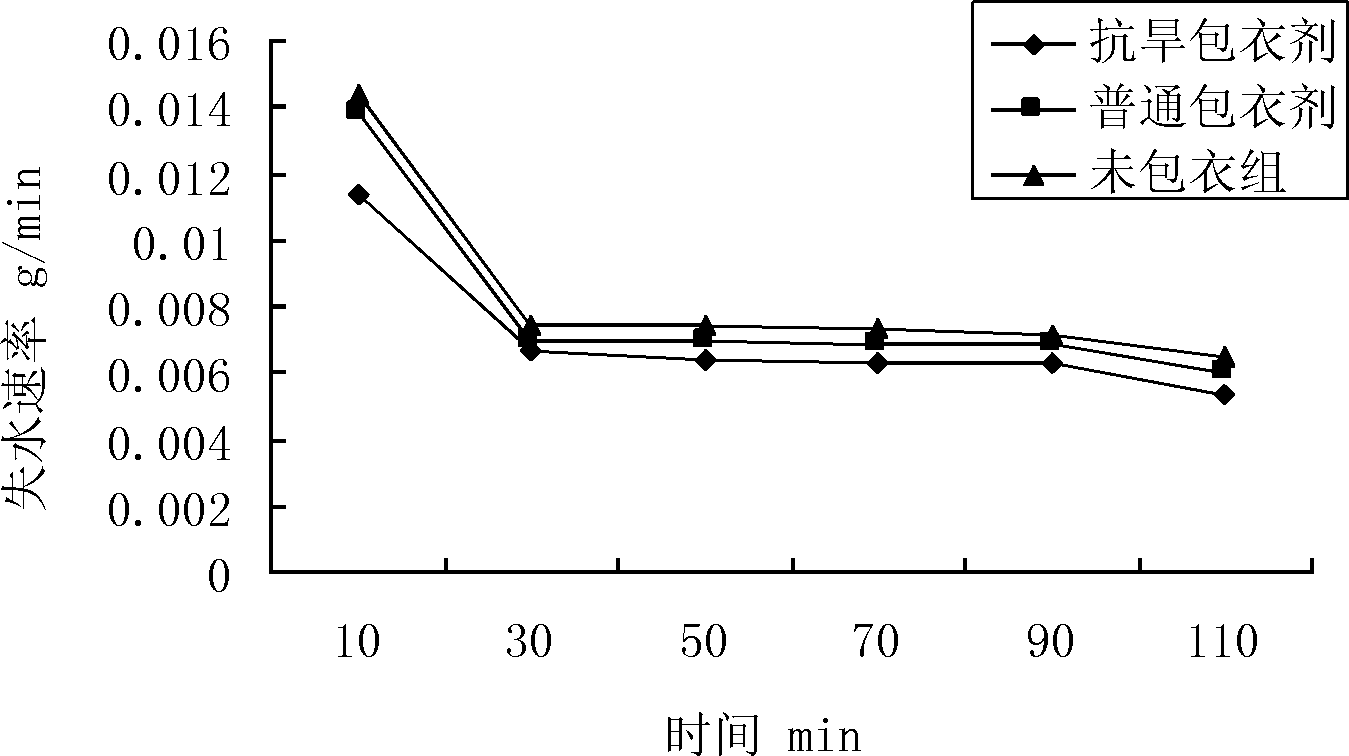

Image

Examples

Embodiment 1

[0033] Weigh 100g of distilled water, 8g of ethylene glycol, 2g of sodium carboxymethylcellulose, 2g of Nongru No. 500, 2g of sodium dodecylbenzenesulfonate and 6g of mycelium, and add them to the reaction kettle in turn, stir, and high-speed shear After 10 minutes, dissolve completely into a uniform solution (heat if necessary); then add 6g of xanthan gum, 8g of fipronil, and 2g of tebuconazole to the kettle in sequence, make up to 200g with distilled water, and then ball mill for 150min at 1000r / min and normal temperature , to obtain the finished seed coating agent.

Embodiment 2

[0035] Weigh 100g of distilled water, 8g of ethylene glycol, 2g of sodium carboxymethyl cellulose, 2g of NNO, 2g of Tween 80 and 6g of mycelia, and add them into the reaction kettle in turn, stir, and shear at high speed for 10min to dissolve completely and form a uniform solution (heating if necessary); then add 4g of magnesium aluminum silicate, 8g of fipronil, and 2g of tebuconazole to the kettle successively, make up to 200g with distilled water, and then ball mill for 150min at 1000r / min and normal temperature to obtain the seed coat finished product.

Embodiment 3

[0037] Weigh 100g of distilled water, 8g of ethylene glycol, 2g of sodium carboxymethyl cellulose, 2g of Nongru No. 500, 2g of dispersant NNO and 6g of mycelium, and add them into the reaction kettle in sequence, stir, and shear at high speed for 10 minutes until the solution is completely dissolved. Homogeneous solution (heating if necessary); then add 6g gelatin, 10g fipronil, and 2g tebuconazole to the kettle successively, make up to 200g with distilled water, and ball mill for 150min at 1000r / min and normal temperature to obtain the finished seed coating agent .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com