Peroxyacetic acid solution without additives and method for preparing same

A technology of peracetic acid and ultra-pure peracetic acid, which is applied in the field of highly stable peracetic acid solution and its preparation, can solve the problems of increasing the impurity content of peracetic acid, reducing the service life of equipment, environmental pollution, etc., and improving the reaction yield , reduce by-products, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

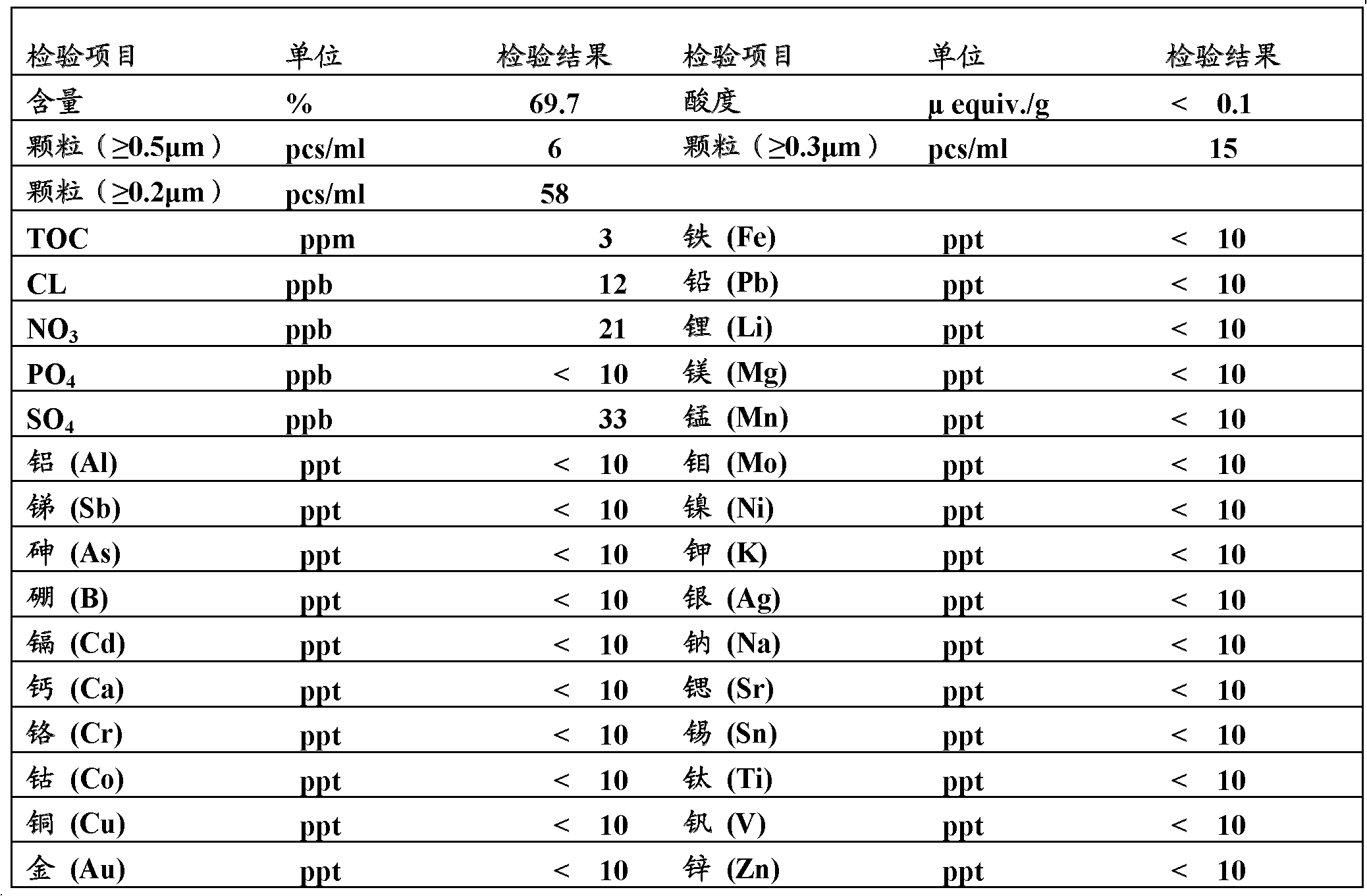

Embodiment 1

[0037] This embodiment provides a method for preparing high-purity hydrogen peroxide with a mass concentration of 70%, which includes the following steps:

[0038] (1), preparation of 70% high-purity EL grade hydrogen peroxide

[0039] 1. Take commercially available ordinary hydrogen peroxide (70wt%), control the temperature at 0-15°C, then pass the hydrogen peroxide through a macroporous adsorption resin adsorption column (AB series macroporous adsorption resin from Bengbu Tianxing Resin Company in Anhui Province), control the flow rate to 500L / H, and the resin Treatment life (<2000 times resin volume), reduce the content of organic impurities in hydrogen peroxide to below 20ppm.

[0040] 2. Pass the hydrogen peroxide through step 1 through a cation exchange column (styrene-based cation exchange resin, trade mark China 732), and control the flow rate to 500 L / H. Reduce the impurity content of metal ions in hydrogen peroxide to below 100ppb.

[0041] ③. Pass the hydrogen per...

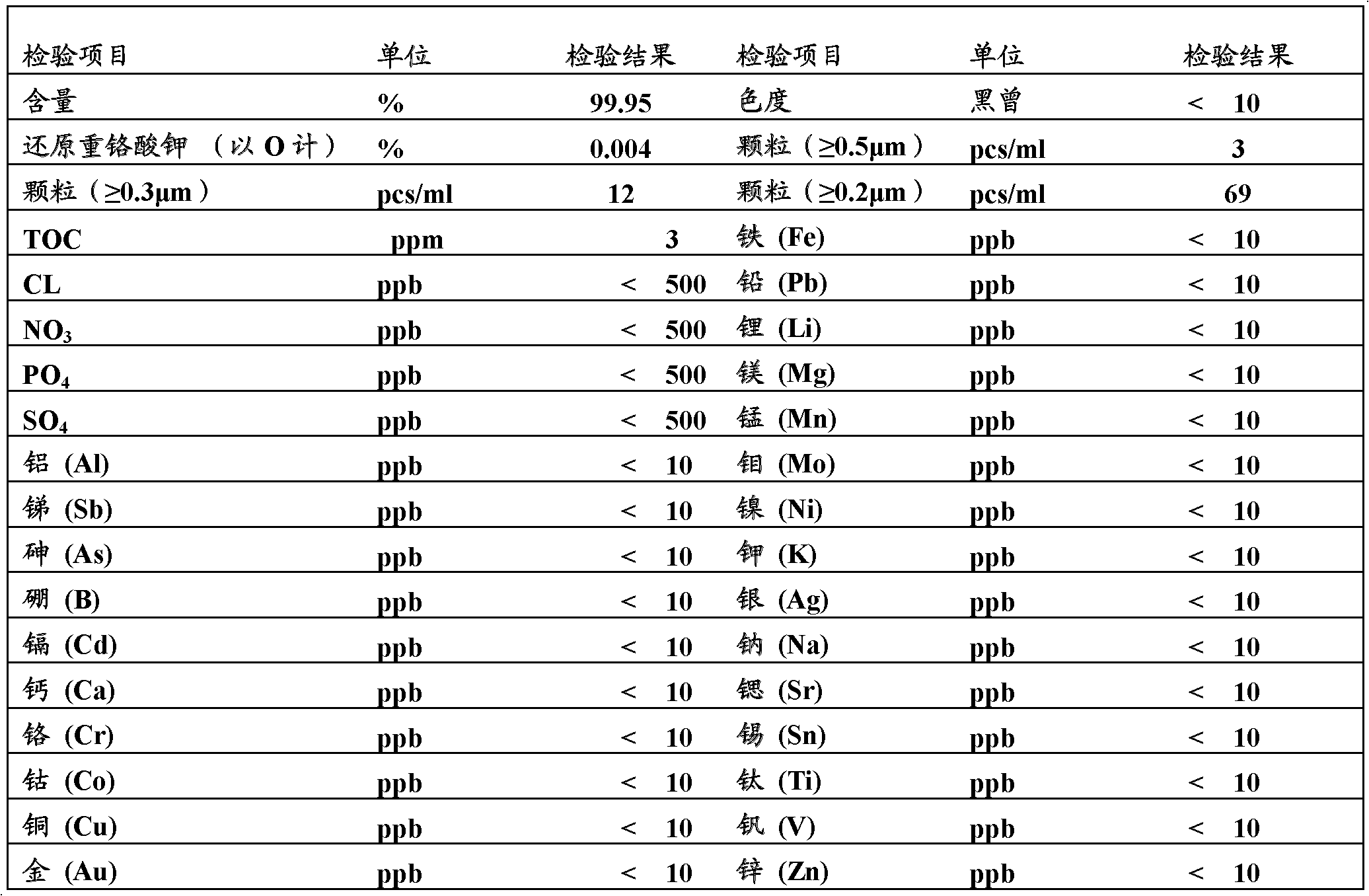

Embodiment 2

[0056] This embodiment provides a kind of preparation method of the high-purity glacial acetic acid of mass concentration>99.9%, specifically as follows:

[0057] (1) glacial acetic acid is passed through molecular sieves (3A-EPG, 3A-PPG, particle diameter 3~5mm), the moisture content in glacial acetic acid is reduced to below 0.01wt%;

[0058] (2) According to the inspection situation of incoming materials, potassium permanganate is added in a ratio of 0.1% to 0.01% by mass to prepare distillation raw materials, reduce the amount of reducing substances such as formic acid and acetaldehyde in the raw materials, and reduce the reducing substance quality from 0.3% to 0.03% or less.

[0059] (3) Pass glacial acetic acid into the rectification tower for rectification, the cooling water flow rate is 5±1L / H, the steam pressure is 0.10±0.05Mpa, the feed flow rate is 200±50L / H, the tower top temperature is 117.1±0.1°C, and the anion The concentration is reduced to below 200ppb, and t...

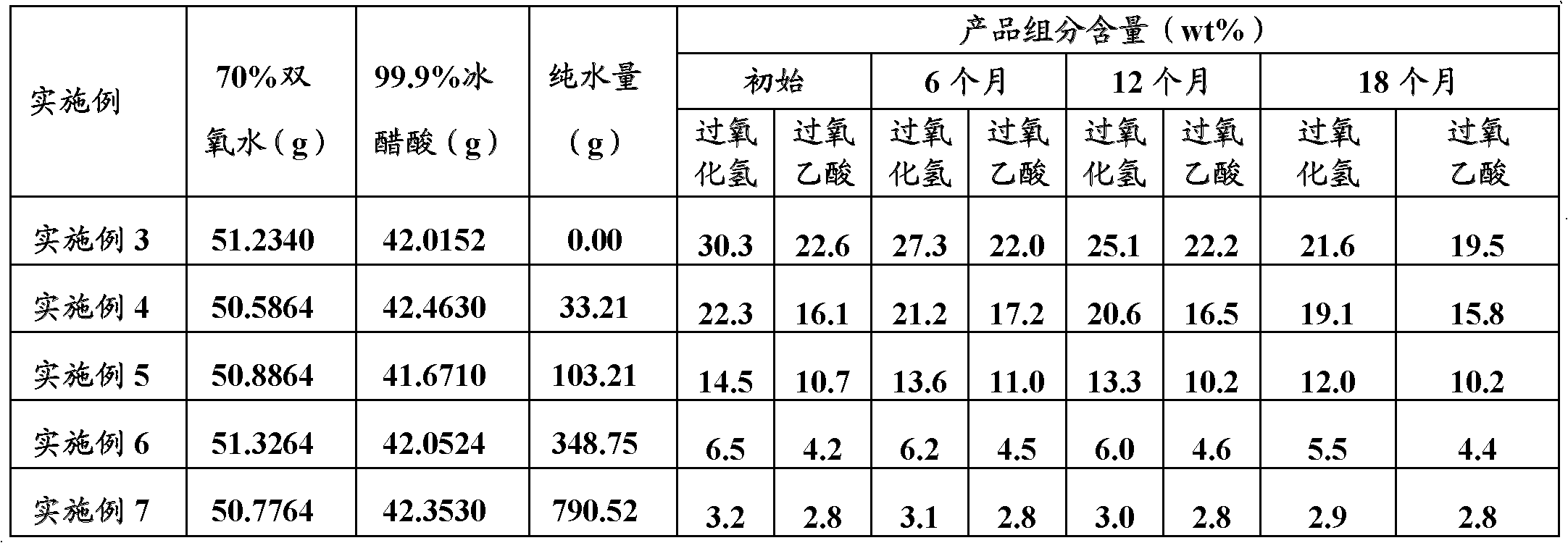

Embodiment 3~7

[0065] Present embodiment provides the method for preparing peracetic acid solution and ultrapure peracetic acid solution without additive simultaneously, and it comprises the steps:

[0066] (1) Clean the reaction kettle, packaging barrel, rectification tower and pipeline used in production. Taking the packaging barrel as an example, the cleaning process is as follows: In the clean room, soak the packaging barrel with distilled water with a conductivity greater than 18.2M for 12 hours , Then rinse with 0.4Mpa pressure distilled water, and drain; then fill the packaging barrel with 35% high-purity peracetic acid solution, and store it at 25°C for 24 hours, drain the peracetic acid, and use distilled water with a conductivity greater than 18.2M Clean, purify compressed air and blow dry for later use, test the distilled water for cleaning, and the content of various pollutants in it is less than 5ppb. Store in a cleaned packaging drum with 35% peracetic acid solution, store at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com