System for separating ammonia and carbon dioxide mixed gas

A carbon dioxide and separation system technology, applied in the preparation/separation of ammonia, carbon compounds, separation methods, etc., can solve the problems of high energy consumption, large steam consumption, and increased energy consumption of the separation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

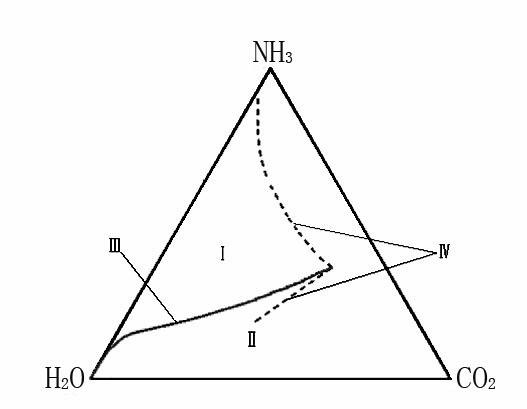

Method used

Image

Examples

Embodiment 1

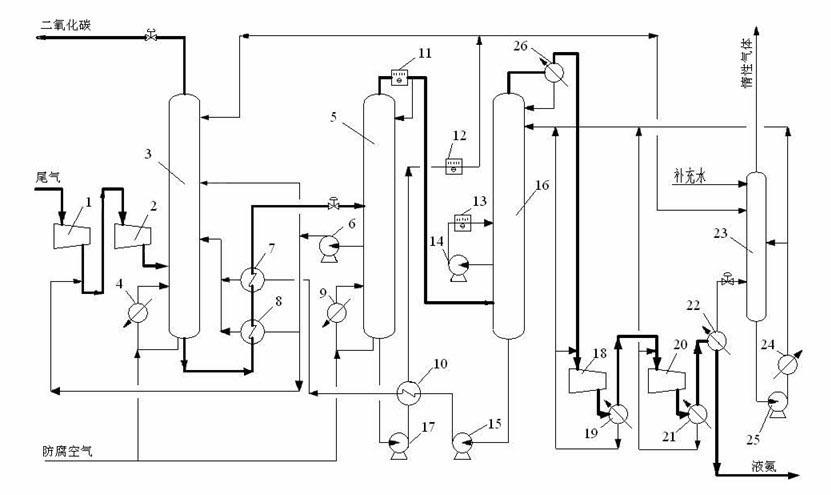

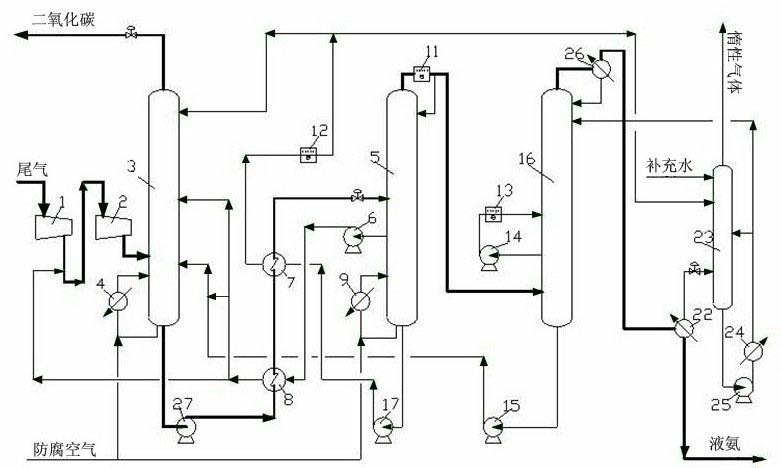

[0043] The separation system used for the mixed gas of ammonia and carbon dioxide described in this embodiment is as follows: figure 2 shown, including:

[0044] A carbon dioxide separation tower 3, a reboiler 4 is attached to the bottom of the carbon dioxide separation tower 3, and a heat exchanger 8 and a heat exchanger 7 are connected to the outlet of the ammonia-carbon aqueous solution at the bottom of the carbon dioxide separation tower 3;

[0045] Be connected with described carbon dioxide separation tower 3 and be provided with water separation tower 5, reboiler 9 is attached at the bottom of water separation tower 5, top is provided with reflux condenser 11, and described reflux condenser 11 is air cooler, and described water separation tower The middle part of 5 is provided with side line extraction pump 6, and described side line extraction pump 6 is extracted dilute ammonia-carbon aqueous solution from the side line of described water separation tower 5; Pump 17, ...

Embodiment 2

[0054] The separation system for the mixed gas of ammonia and carbon dioxide described in this embodiment is the same as that in Embodiment 1, and the separation method based on the separation system described in this embodiment is:

[0055] a. The melamine tail gas with a pressure of 4 bar is sent to the tail gas compressor section 1 for compression, the outlet pressure of the first section is 8.5 bar, the temperature rises to 234 ° C, and the temperature drops after spraying the dilute ammonia-carbon aqueous solution extracted from the side line of the water separation tower 5 to 140°C. Then it is sent to the second section 2 of the compressor for further compression, and the gas is compressed to 15bar and 223°C.

[0056] b. The compressed gas is sent to the bottom of the carbon dioxide separation tower 3, and the upper, middle and lower parts of the carbon dioxide separation tower 3 are fed into the water from the bottom of the water separation tower 5 and the dilute ammoni...

Embodiment 3

[0060] The separation system for the mixed gas of ammonia and carbon dioxide described in this embodiment is the same as that in Embodiment 1, and the separation method based on the separation system described in this embodiment is:

[0061] a. The melamine tail gas with a pressure of 4 bar is sent to the tail gas compressor section 1 for compression, the outlet pressure of the first section is 10.1 bar, the temperature rises to 257 ° C, and the temperature drops after spraying the dilute ammonia-carbon aqueous solution extracted from the side line of the water separation tower 5 to 140°C. Then it is sent to the second stage of the compressor to continue compression, and the gas is compressed to 25bar and 258°C.

[0062] b. The compressed gas is sent to the bottom of the carbon dioxide separation tower 3, and the upper, middle and lower parts of the carbon dioxide separation tower 3 are fed into the water from the bottom of the water separation tower 5 and the dilute ammonia c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com