Liquid concrete anti-freezing agent

A concrete and antifreeze technology, applied in the field of liquid concrete antifreeze, winter construction engineering, can solve the problems of steel corrosion, methanol volatilization, alkali return, etc., to achieve durable service life, short setting time, slump maintained Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

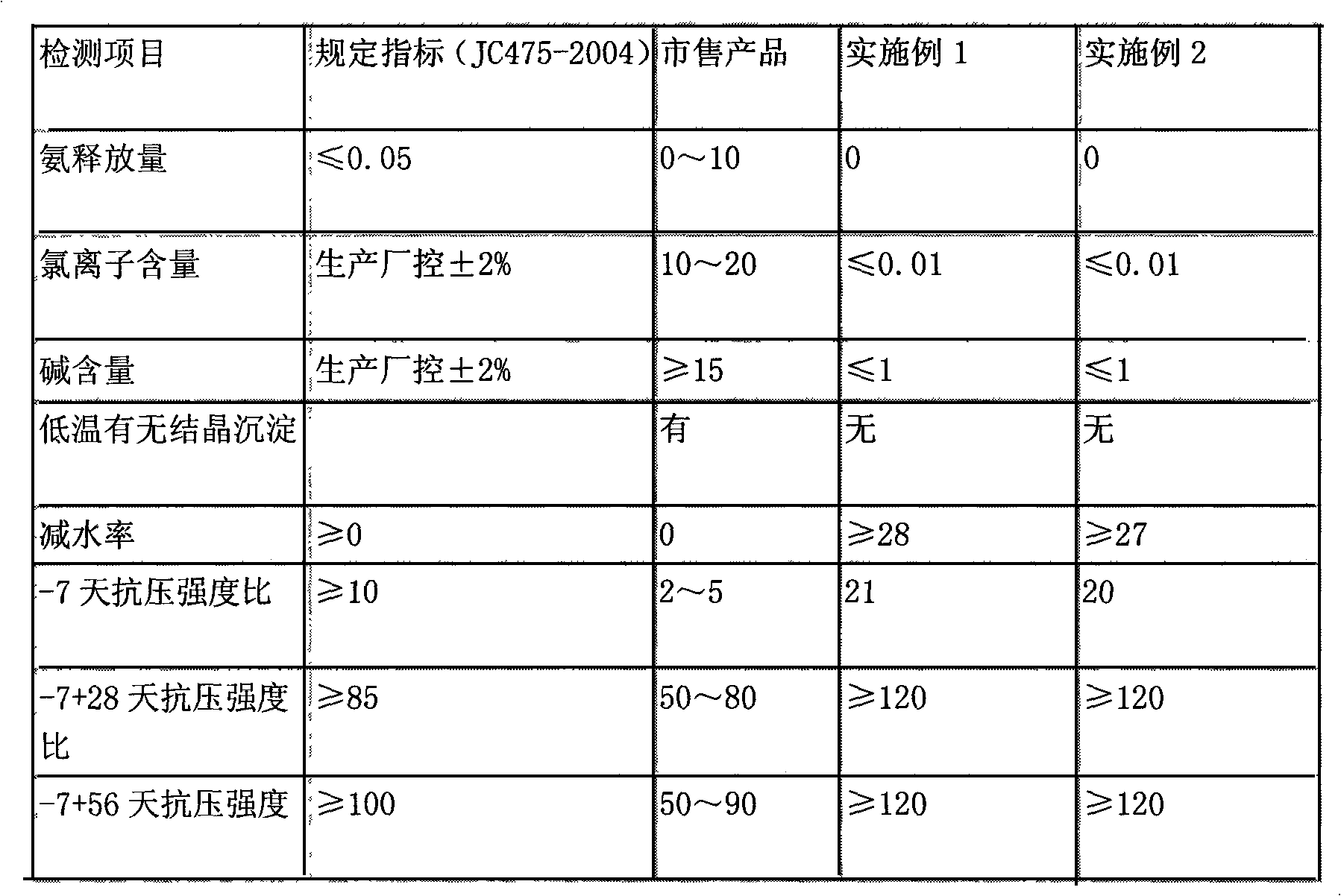

Examples

Embodiment 1

[0010] First, prepare polycarboxylate water reducer: put deionized water for production, polyisoprenyl methoxy macromonomer ether and maleic anhydride (the weight ratio of the three is 0.8:1:0.3) into the reactor , warming up to 75°C, adding hydrogen peroxide with a mass concentration of 35%, stirring, the weight ratio of the hydrogen peroxide to polyisoprenyl methoxy macromonomer ether is 0.001:1; warming up to 90°C, adding persulfuric acid dropwise Sodium and initiator solution, the weight ratio of sodium persulfate, initiator, and polyisoprenyl methoxy macromonomer ether is 0.001:0:002:1, and the initiator thioglycolic acid is added dropwise in 2-3 After hours of dripping, keep warm for 1-2 hours, after cooling down to 50°C, add a sodium hydroxide solution with a mass concentration of 30%, until the solution weight concentration in the reactor is about 40%, to obtain a polycarboxylate superplasticizer. Weigh 15 parts by weight of polycarboxylate high-performance water reduc...

Embodiment 2

[0012] The preparation method of the polycarboxylate high-performance water reducer is the same as in Example 1. Weigh 30 parts by weight of polycarboxylate high-performance water reducer, 0.1 part by weight of nonylphenol polyoxyethylene ether, 2 parts by weight of lithium sulfate and 5 parts by weight of triisopropanolamine, mix well, stir for 0.5h, add 50 Parts by weight of water can be stirred for 20 minutes.

[0013] The antifreeze of this embodiment was tested for performance, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com