Method improving manufacturing process of crystalline silicon solar cell through arsenic ion implantation

A solar cell, ion implantation technology, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems such as reducing minority carrier lifetime and battery efficiency, increasing surface recombination rate, increasing surface density of states, etc., to achieve large-scale The effect of mass production, improvement of minority carrier lifetime, and reduction of surface density of states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

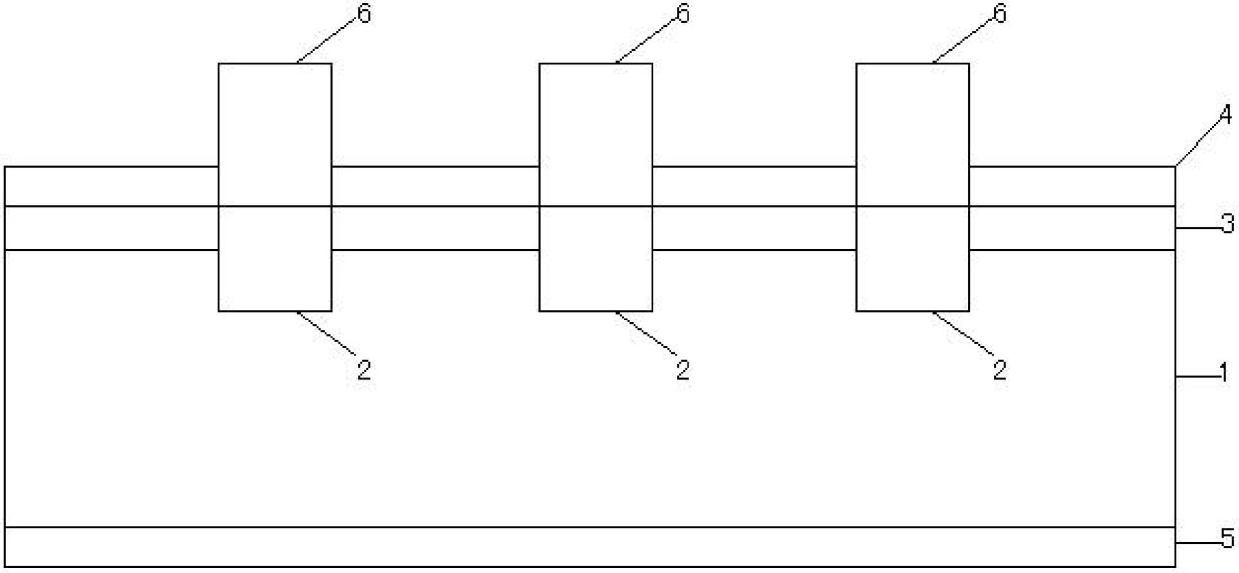

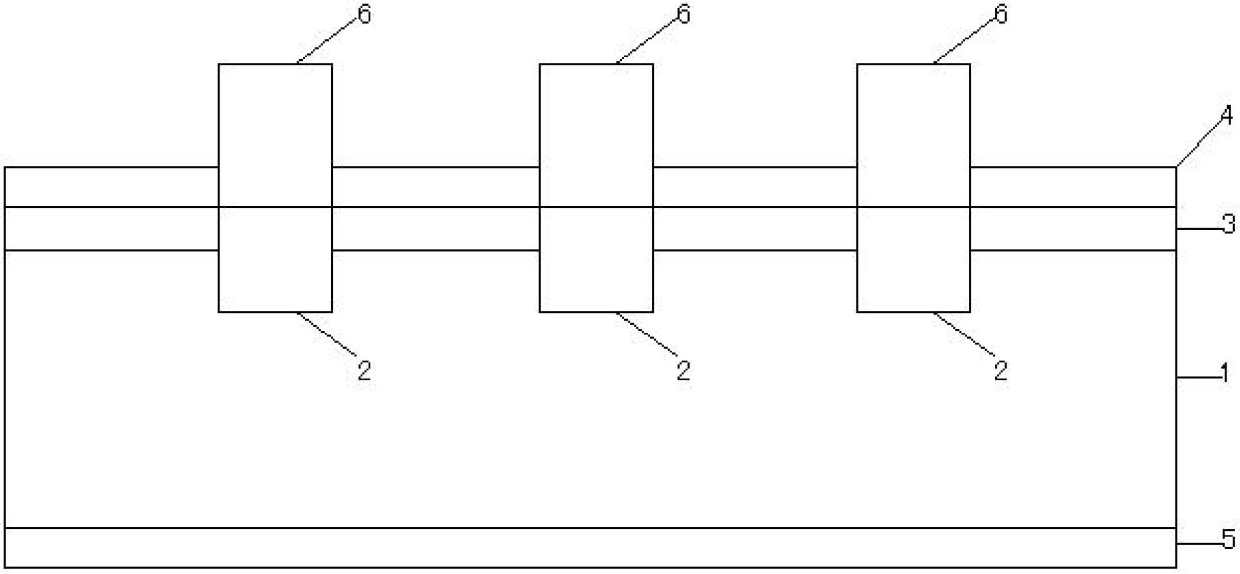

[0031] This embodiment describes a crystalline silicon solar cell formed by ion-implanting arsenic, which includes, from the front to the back (the front refers to the light-receiving surface, and the back refers to the non-light-receiving surface) sequentially: a silver metal positive electrode 6 on the front, nitrogen Silicone anti-reflection film 4, n+ region 3 formed by ion implantation of arsenic on the front (hereinafter referred to as n+ region 3), n+ diffusion layer 2 formed by diffusion of phosphorus in the designated region on the front, silicon substrate 1 and aluminum back electric field 5 on the back.

[0032] The specific manufacturing process steps are as follows:

[0033] Performing damage removal and surface texturing on the P-type crystalline silicon substrate 1;

[0034] A patterned diffusion junction is performed on a designated area on the front side of the silicon substrate 1 . Deposit silicon oxide or silicon nitride on the front side of the silicon sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com