Method for preparing silicon carbide nanometer particle and composite material thereof by evaporating solid raw materials

A nanoparticle and composite material technology, applied in the field of nanomaterial preparation, can solve the problems of complex process, high cost, easy introduction of external impurities, etc., and achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take micron-sized carbon powder and silicon powder with a molar ratio of 1:0.9, mix them evenly and grind them, press them into a block under a pressure of 25MPa, put them into a graphite crucible as an anode, and a graphite rod as a cathode, adjust the distance between the two electrodes to 30mm . Vacuum the reaction chamber to about 10 -2 Pa, filled with argon and hydrogen at a ratio of 2:1 to reach 5×10 4 Pa and 2.5×10 4 Pa. Turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the two electrodes and stabilize the arc, evaporate the bulk target, form atomic clusters and gather them into nanoparticles and deposit them on the wall of the reaction chamber, and collect the powder through passivation process.

Embodiment 1

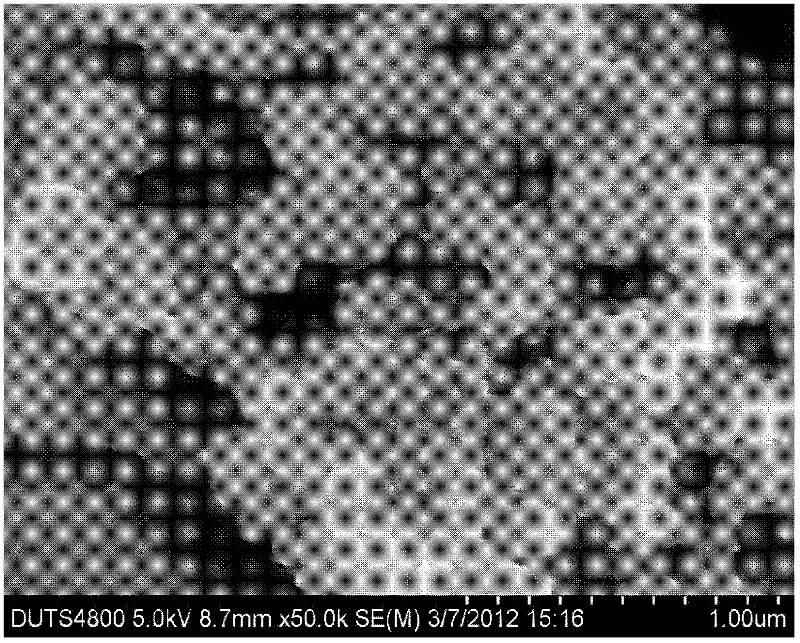

[0027] The SEM image of silicon carbide nanoparticles obtained in embodiment one is as follows figure 1 Shown as spherical particles.

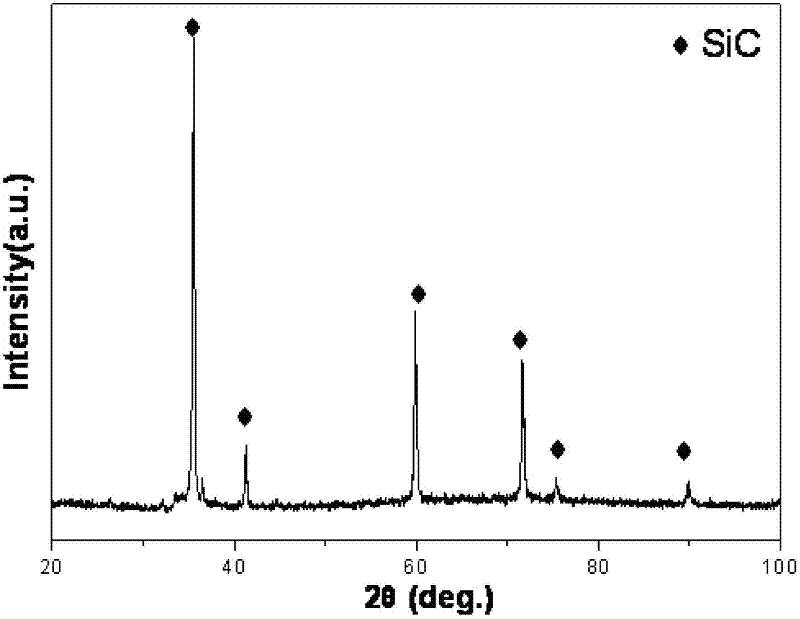

[0028] The obtained silicon carbide nanoparticles XRD pattern of embodiment one is as follows figure 2 As shown, it is shown as single-phase silicon carbide.

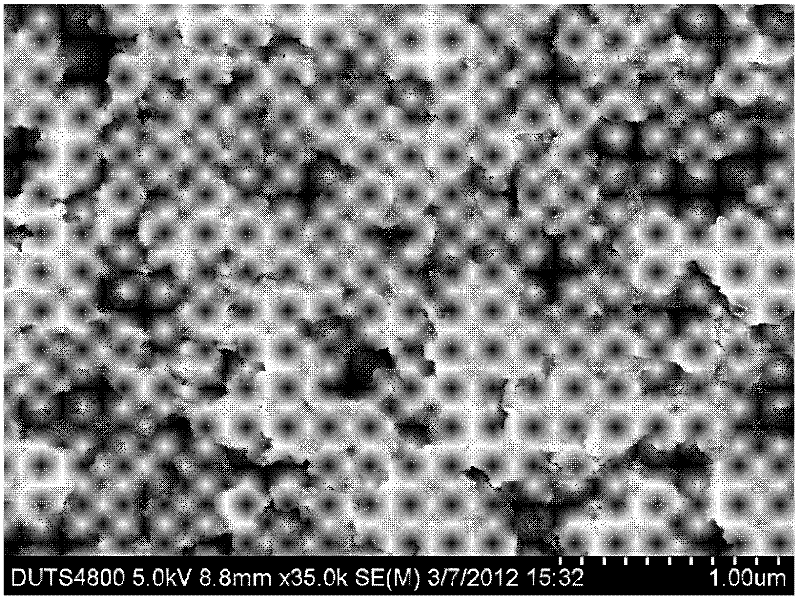

Embodiment 2

[0030] Take micron-sized carbon powder and silicon powder with a molar ratio of 4.3:1, mix them evenly and grind them, press them into a block under a pressure of 25MPa, put them into a graphite crucible as an anode, and a graphite rod as a cathode, adjust the distance between the two electrodes to 30mm . Vacuum the reaction chamber to about 10 -2 Pa, filled with argon and hydrogen at a ratio of 11:1 to reach 5.5×10 4 Pa and 5×10 3 Pa. Turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the two electrodes and stabilize the arc, evaporate the bulk target, form atomic clusters and gather them into nanoparticles and deposit them on the wall of the reaction chamber, and collect the powder through passivation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com