Fluorine-containing surfactant modified graphene preparation method for electrode of electric double-layer capacitor

An electric double layer capacitor and surfactant technology, which is applied in the field of preparation of graphene for fluorine-containing surfactant modified electric double layer capacitor electrodes, can solve the problem of hindering the migration rate of electrolyte ions, failing to effectively improve energy density, stearin Acid electrochemical stability is low and other problems, to achieve the effect of reducing equivalent series internal resistance, good interface compatibility, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of fluorosurfactant-modified graphene:

[0038] 1. Preparation of graphene oxide dispersion and fluorine-containing surfactant solution

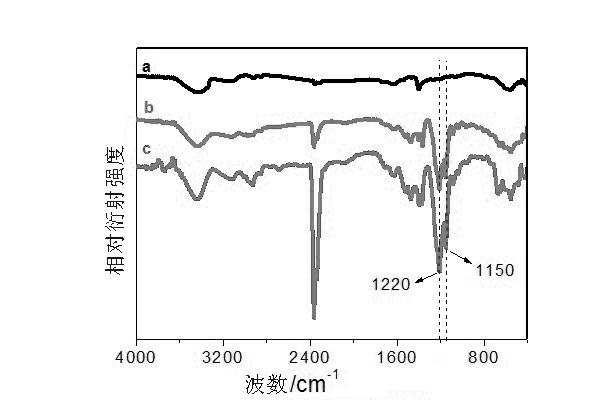

[0039] Add 50mg of graphene oxide powder into 100mL of deionized water, and disperse ultrasonically at a frequency of 20kHz for 48h to obtain a graphene oxide dispersion; add 5mg of sodium perfluorooctanesulfonate (infrared spectrum as figure 1 As shown in c) was added to 10mL of deionized water, and ultrasonically dispersed at a frequency of 20kHz for 6h to obtain a sodium perfluorooctane sulfonate solution;

[0040] 2. Surface modification of graphene oxide

[0041]Add the sodium perfluorooctane sulfonate solution prepared in step 1 into the graphene oxide dispersion, stir at 20°C and 500 rpm for 12 hours, filter with suction, keep the filter cake, and dry it in vacuum at 180°C for 24 hours to obtain perfluorooctane Sodium sulfonate modified graphene oxide powder;

[0042] 3. Reduction of surface-modified graphene ox...

Embodiment 2

[0047] Preparation of fluorosurfactant-modified graphene:

[0048] 1. Preparation of graphene oxide dispersion and fluorine-containing surfactant solution

[0049] Add 50mg of graphene oxide powder into 50mL of deionized water, and disperse ultrasonically at a frequency of 100kHz for 6h to obtain a graphene oxide dispersion; add 10mg of perfluoroalkyl ethoxy ether alcohol to 10mL of deionized water, and Ultrasonic dispersion for 12 hours to obtain perfluoroalkyl ethoxy ether alcohol solution;

[0050] 2. Surface modification of graphene oxide

[0051] Add the perfluoroalkyl ethoxy ether alcohol solution prepared in step 1 into the graphene oxide dispersion, stir at 50°C and 1000rpm for 12h, filter with suction, keep the filter cake, and dry it in vacuum at 160°C for 6h to obtain the complete Fluoroalkyl ethoxy ether alcohol modified graphene oxide powder;

[0052] 3. Reduction of surface-modified graphene oxide

[0053] Wrap the perfluoroalkyl ethoxy ether alcohol-modified...

Embodiment 3

[0056] Preparation of fluorosurfactant-modified graphene:

[0057] 1. Preparation of graphene oxide dispersion and fluorine-containing surfactant solution

[0058] Add 50mg of graphene oxide powder into 25mL of deionized water, and disperse it by ball milling for 12h to obtain a graphene oxide dispersion; add 50mg of perfluorooctyl quaternary ammonium salt into 100mL of deionized water, and disperse with ultrasonic waves at a frequency of 100kHz for 6h, Obtain perfluorooctyl quaternary ammonium salt solution;

[0059] 2. Surface modification of graphene oxide

[0060] Add the perfluorooctyl quaternary ammonium salt solution prepared in step 1 into the graphene oxide dispersion, stir at 100°C and 2000rpm for 6h, filter with suction, keep the filter cake, and vacuum dry at 170°C for 12h to obtain perfluorooctyl quaternary ammonium Salt-modified graphene oxide powder;

[0061] 3. Reduction of surface-modified graphene oxide

[0062] Wrap the perfluorooctyl quaternary ammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com