Base oil for cooling of device, device-cooling oil containing the base oil, device to be cooled by the cooling oil, and device cooling method using the cooling oil

A base oil and machine technology, applied in the base material, petroleum industry, lubricating composition, etc., can solve the problems of enlarged cooling device, inability to directly cool the motor coil, difficulty in ensuring large cooling capacity, etc., and achieve electrical insulation and Excellent thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

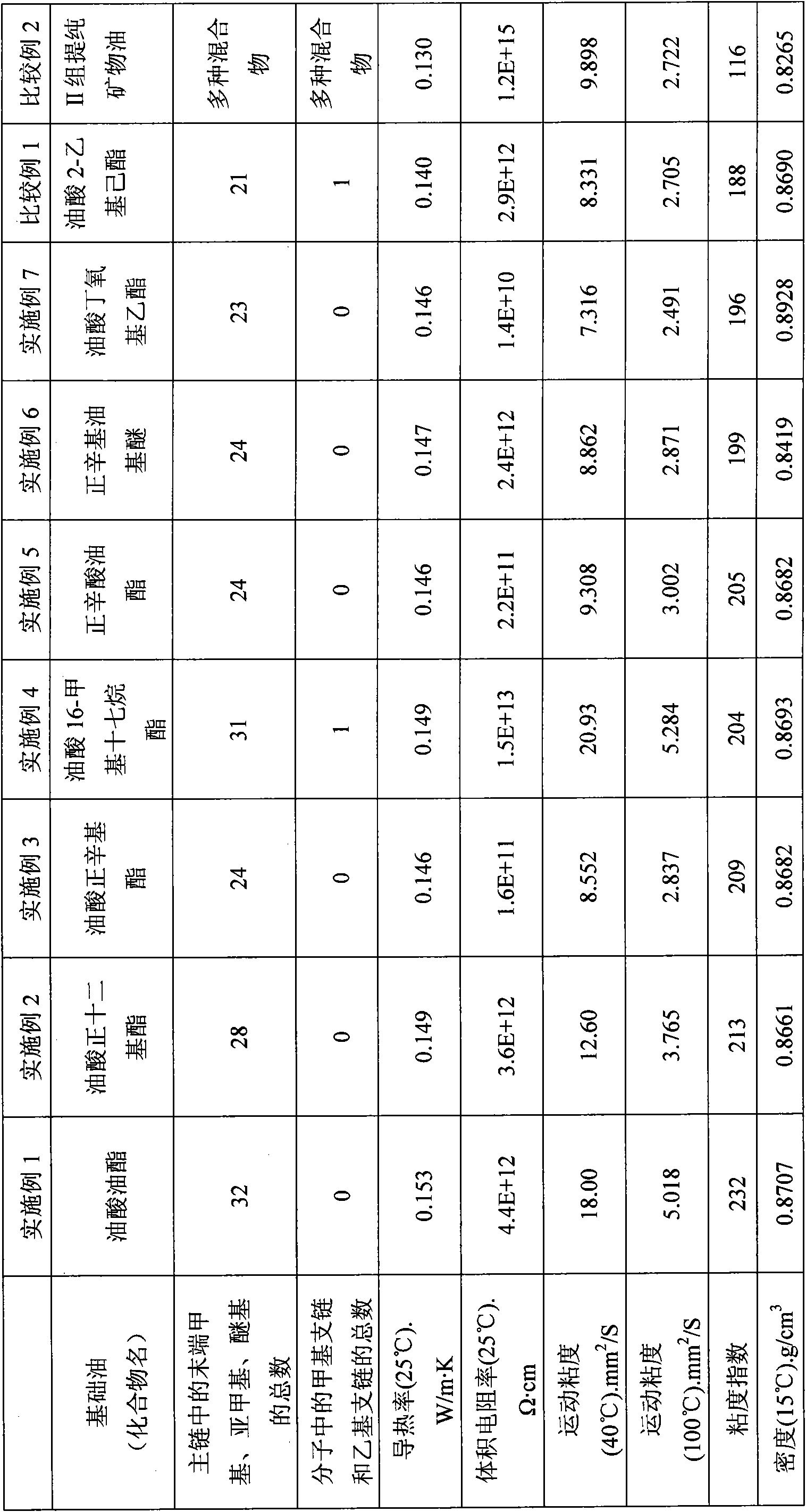

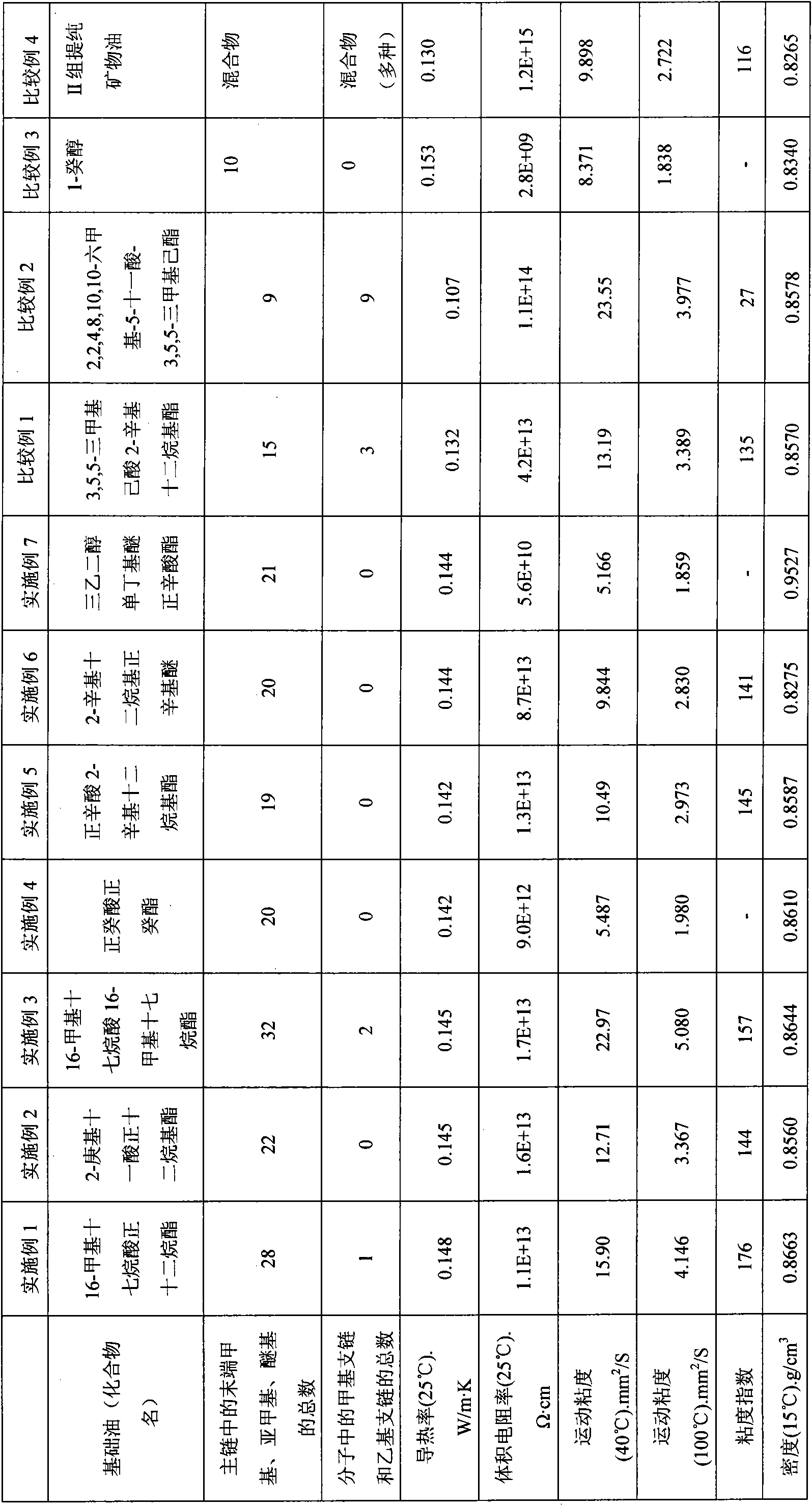

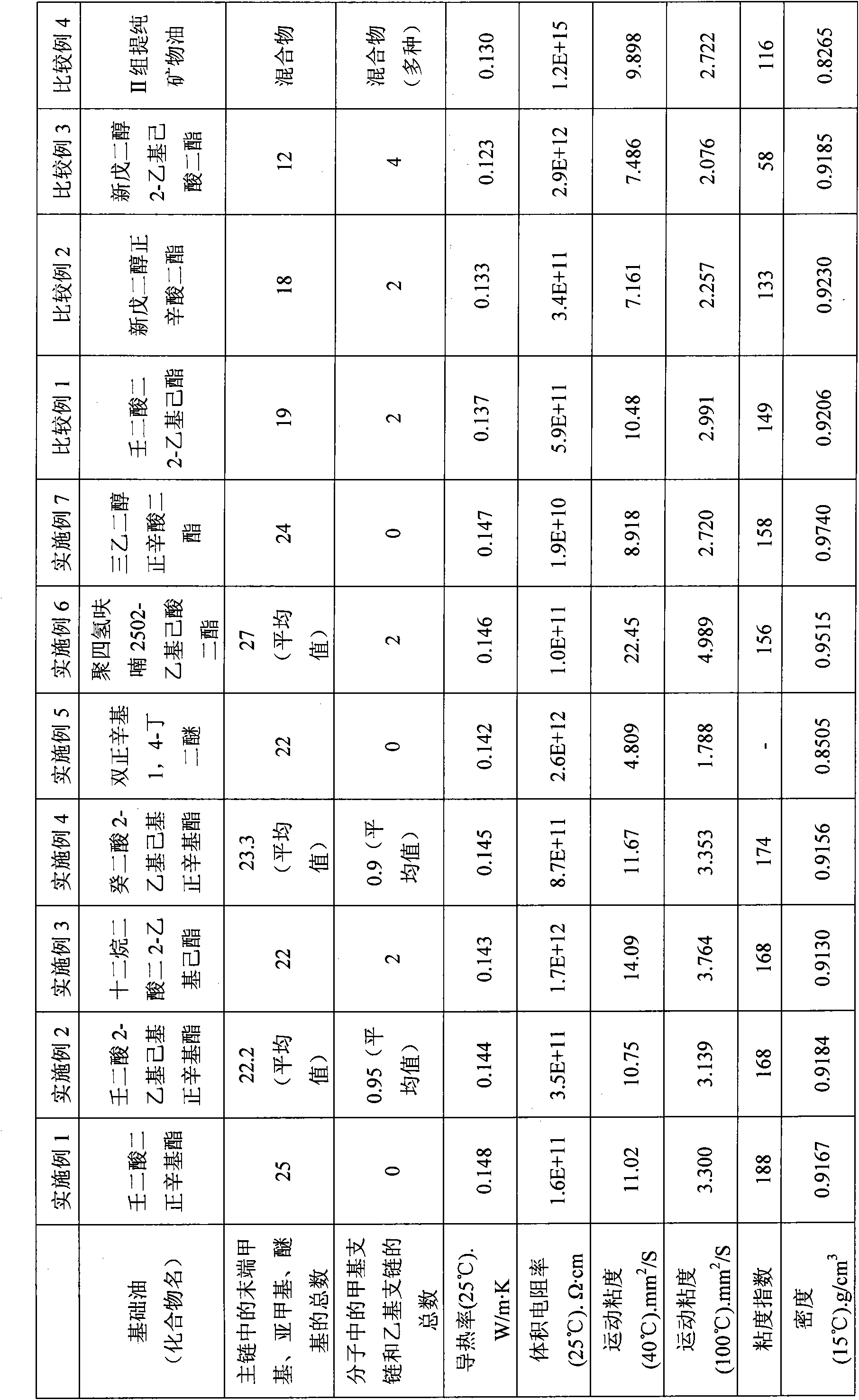

[0034] The basic component of the base oil for machine cooling (hereinafter simply referred to as "base oil") according to the first embodiment of the present invention is at least one of oleyl ester (oleic acid ester, oleyl alcohol ester) and oleyl ether.

[0035]In addition, the total number of terminal methyl groups, methylene groups, and ether groups in the main chain of the oleyl ester and the oleyl ether is 23 or more, and the total number of methyl branches and ethyl branches in the molecule is 1 the following. Here, the main chain refers to the longest chain-like structural part of the molecule.

[0036] Hereinafter, the first embodiment of the present invention will be described in detail.

[0037] In order to improve the thermal conductivity from liquid molecules, it is important to optimize the transfer of thermal vibration energy due to intermolecular conflicts, and to design the molecules so that the vibration energy does not diffuse in the molecules. Also, to i...

Embodiment 1

[0067] 127 g of oleic acid (a reagent produced by Tokyo Chemical Industry Co., Ltd.), 145 g of oleyl alcohol (a reagent produced by Tokyo Chemical Industry Co., Ltd.), and 100 mL of mixed xylene (a reagent produced by Tokyo Chemical Industry Co., Ltd.) were added to a 500 mL four-necked flask with a Dean-Stark device Reagent) and 0.1 g of titanium tetraisopropoxide (reagent manufactured by Tokyo Chemical Industry Co., Ltd.) were reacted at 140° C. for 2 hours while stirring in a nitrogen stream while distilling off water. Then, washing with saturated saline and washing with a 0.1-prescribed sodium hydroxide aqueous solution was performed three times each, and dried over anhydrous magnesium sulfate (a reagent manufactured by Tokyo Chemical Industry Co., Ltd.). After filtering magnesium sulfate, excess raw material alcohol was distilled off, and 215 g of oleic acid oleyl esters were obtained. Various physical properties (thermal conductivity, volume resistivity, kinematic viscos...

Embodiment 2

[0069] Except having used 101 g of n-dodecyl alcohols (Tokyo Chemical Industry Co., Ltd. reagent) instead of 145 g of oleyl alcohols, it carried out similarly to Example 1, and obtained 184 g of n-dodecyl oleates. Various physical properties (thermal conductivity, volume resistivity, kinematic viscosity, viscosity index, density) were measured for this compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com