A kind of preparation method of diatomite loaded nitrogen-doped nano-tio2 photocatalytic material

A technology of photocatalytic material and diatomaceous earth, applied in the direction of protection device against harmful chemical agents, etc., can solve the problem of low utilization rate of natural light of photocatalyst, and achieve the effect of improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

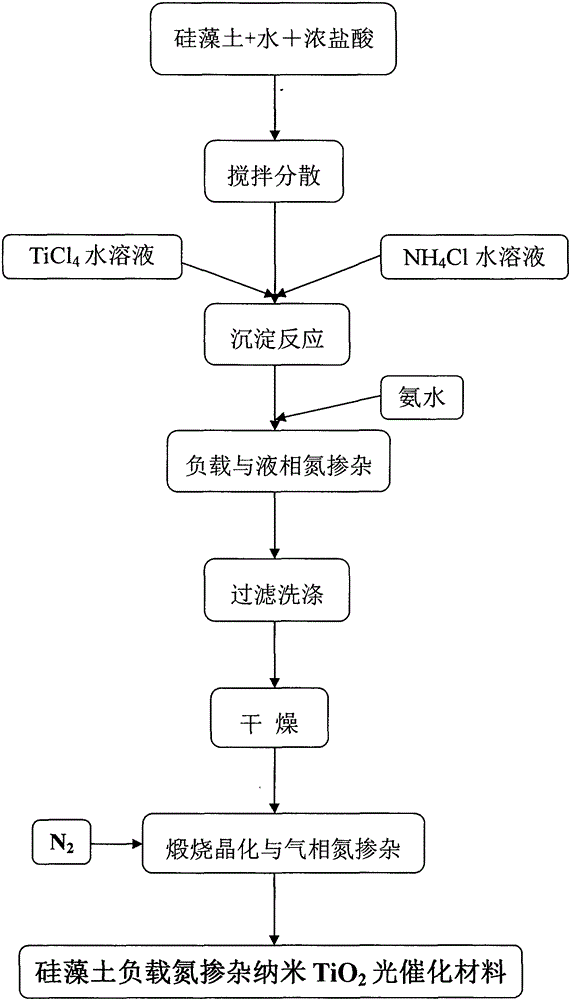

Method used

Image

Examples

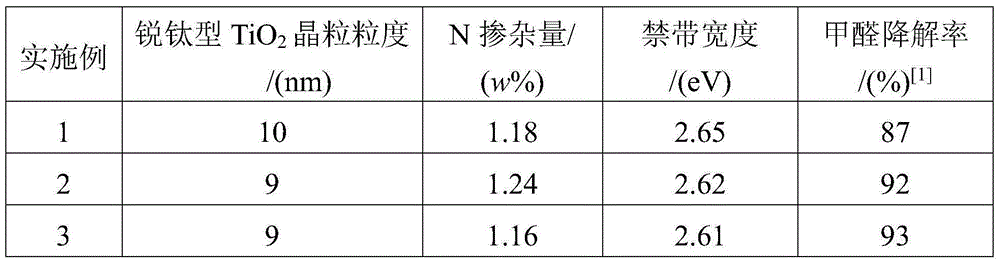

Embodiment 1

[0022] Take 100g of dry diatomite with a diatom content of 84.68% and 3000ml of deionized water to remove the 325-mesh sieve residue and add 100g of deionized water to the laboratory reactor to stir and make slurry, add hydrochloric acid to adjust the pH value of the slurry to 2; 200ml of titanium tetrachloride aqueous solution with a mass concentration of 50% and 150ml of ammonium chloride aqueous solution with a concentration of 200g / L; make 30% concentrated ammonia water and deionized water into an ammonia solution with a volume ratio of 1:2.0 and add dropwise into the slurry at a rate of 2.4ml / min; stop the dropwise addition when the pH value of the system is 9.0; react at a temperature of 70°C for 2.0h and then filter and wash with water; the washed filter cake is dried at 105°C and beaten After dispersing, heat-preserve and calcinate at 600°C for 2 hours in a laboratory rotary tube furnace under the condition of nitrogen gas.

Embodiment 2

[0024] Take 100g of beneficiation diatom concentrate with a diatom content of 88.39%, add 3000ml of deionized water into a laboratory reactor and stir to make slurry, add hydrochloric acid to adjust the pH value of the slurry to 2; 200ml of titanium tetrachloride aqueous solution and 150ml of ammonium chloride aqueous solution with a concentration of 200g / L; make 30% concentrated ammonia water and deionized water into an ammonia solution with a volume ratio of 1:2.0 and add it dropwise to the slurry at a rate of 2.4 ml / min; stop dropping when the pH value of the system is 9.0; react at a temperature of 70°C for 2.0h and then filter and wash with water; the washed filter cake is dried and dispersed at 105°C and then rotated in the laboratory Calcination at 600°C for 2 hours under the condition of nitrogen in the furnace.

Embodiment 3

[0026] Take 100g of calcined diatomite with a diatom content of 90.79%, add 3000ml of deionized water into a laboratory reactor and stir to make slurry, add hydrochloric acid to adjust the pH value of the slurry to 2; 200ml of titanium chloride aqueous solution and 150ml of ammonium chloride aqueous solution with a concentration of 200g / L; make 30% concentrated ammonia water and deionized water into an ammonia solution with a volume ratio of 1:2.0 and add it dropwise to the slurry at a rate of 2.4ml / min; when the pH value of the system is 9.0, stop the dropwise addition; react at a temperature of 70°C for 2.0h and then filter and wash with water; the washed filter cake is dried at 105°C and dispersed in a laboratory rotary tube furnace Calcination at 600°C for 2 hours under the condition of medium nitrogen flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com