Preparation method of CaWO4 hollow spheres

A hollow ball and air technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of affecting material properties, cumbersome operation process, inconvenient product cleaning, etc., and achieves low reaction temperature, simple raw materials, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

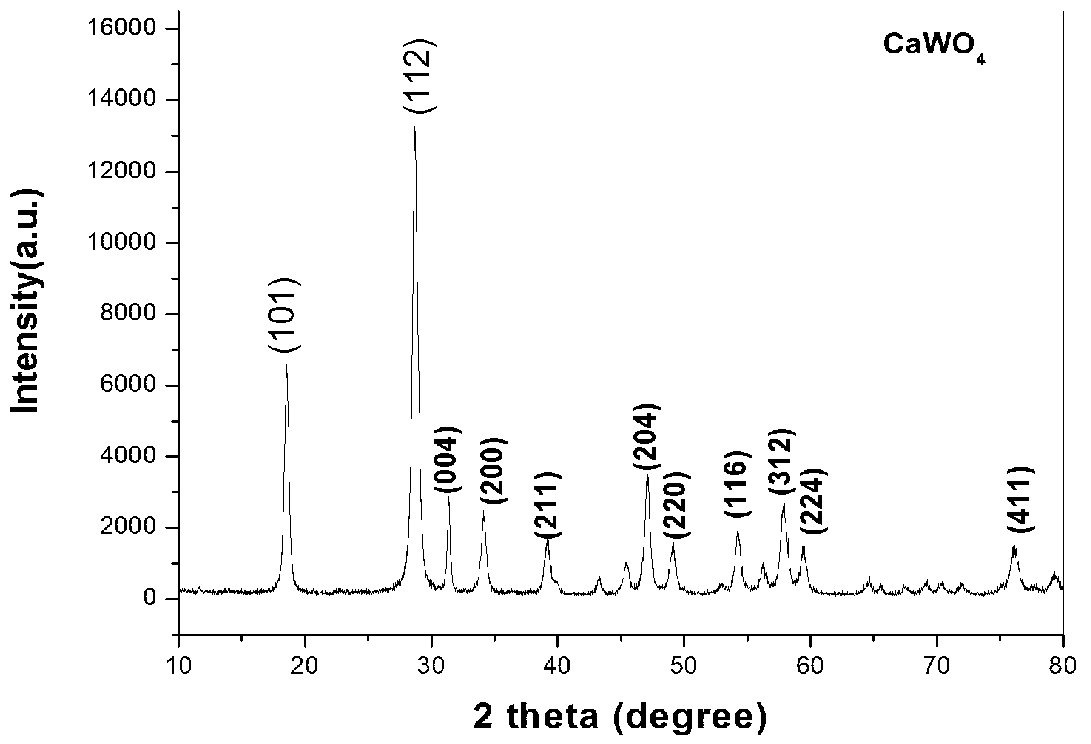

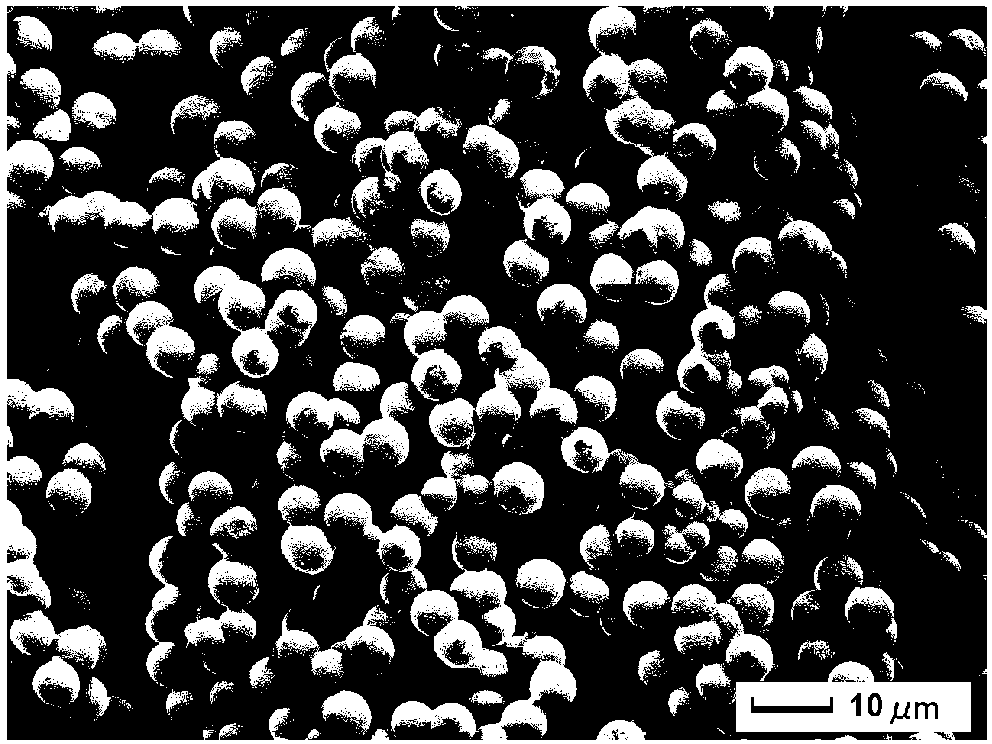

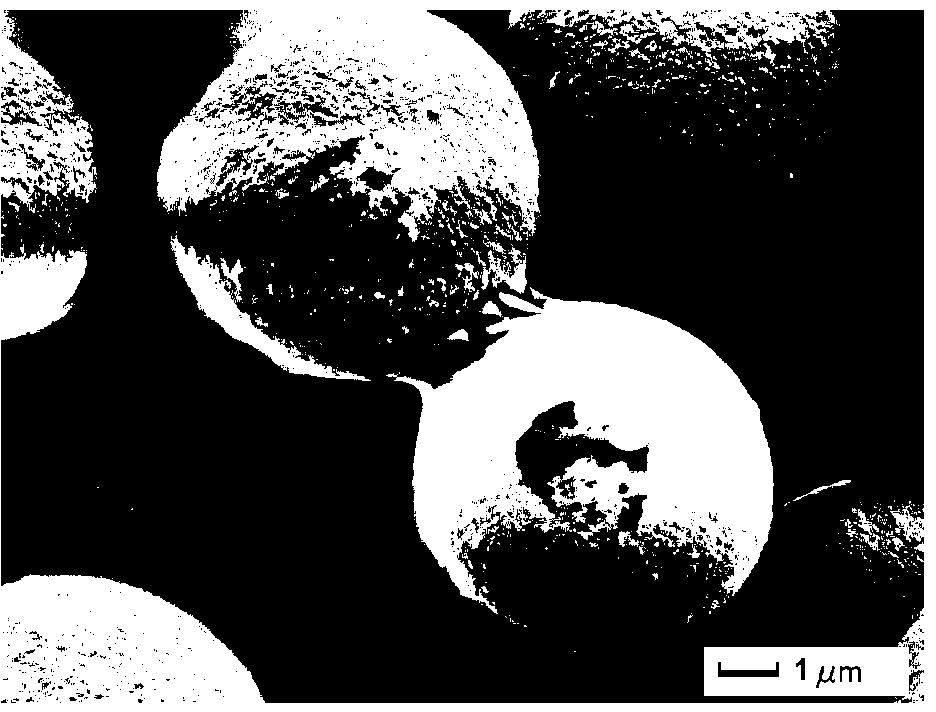

[0028] Under magnetic stirring, 0.2mol / L, 25ml Na 2 WO 4 and 0.2mol / L, 25mlCaCl 2 Mix, adjust the pH value of the mixed solution to 9 with the NaOH of 0.2mol / L and the HCl of 0.2mol / L, stir for 10min, after mixing evenly, transfer the mixed solution into an autoclave with a polytetrafluoroethylene liner. React in a constant temperature box at 160°C for 24 hours, cool down to room temperature with the furnace, open the reaction kettle, decant the upper layer, wash thoroughly with distilled water and absolute ethanol in turn, and filter under reduced pressure at room temperature to obtain a white solid product. Dry at 80°C for 4 hours to obtain dispersed micron CaWO 4 hollow ball. attached figure 1 It is the X-ray diffraction pattern of the product obtained in this example, as can be seen from the figure, no impurity peak appears, indicating that the product is pure CaWO 4 . attached figure 2 It is the low-magnification SEM figure of the product obtained in this embodime...

Embodiment 2

[0030] Under magnetic stirring, 0.2mol / L, 25ml Na 2 WO 4 and 0.2mol / L, 25mlCaCl 2 Mix, adjust the pH value of the mixed solution to 7 with the NaOH of 0.2mol / L and the HCl of 0.2mol / L, stir 10min, after mixing evenly, transfer the mixed solution into an autoclave with a polytetrafluoroethylene liner, React in a constant temperature box at 160°C for 24 hours, cool down to room temperature with the furnace, open the reaction kettle, decant the upper layer, wash thoroughly with distilled water and absolute ethanol in turn, and filter under reduced pressure at room temperature to obtain a white solid product. Dry at 80°C for 4 hours to obtain dispersed calcium tungstate microspheres. As can be seen from the X-ray diffraction pattern of this embodiment, the resulting product CaWO 4 High purity, no other impurities. As can be seen from the SEM image of this embodiment, the CaWO generated under the experimental conditions 4 , the particle dispersibility is better, but the obtain...

Embodiment 3

[0032] Under magnetic stirring, 0.2mol / L, 25ml Na 2 WO 4 and 0.2mol / L, 25mlCaCl 2Mix, adjust the pH value of the mixed solution to 11 with the NaOH of 0.2mol / L and the HCl of 0.2mol / L, stir for 10min, after mixing evenly, transfer the mixed solution into an autoclave with a polytetrafluoroethylene liner. React in a constant temperature box at 160°C for 24 hours, cool down to room temperature with the furnace, open the reaction kettle, decant the upper layer, wash thoroughly with distilled water and absolute ethanol in turn, and filter under reduced pressure at room temperature to obtain a white solid product. Dry at 80°C for 4 hours to obtain dispersed calcium tungstate microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com