Preparation method and application of indole acetic acid (IAA) molecularly imprinted polymer (MIP)

A molecular imprinting, indole acetic acid technology, applied in the field of analytical chemistry, can solve the problems of limited specificity and high price, and achieve the effects of enhanced selectivity, low cost and simple fiber processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

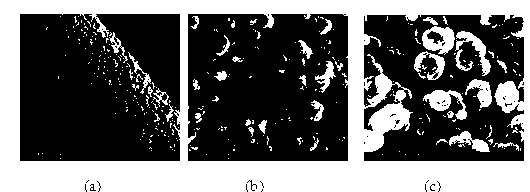

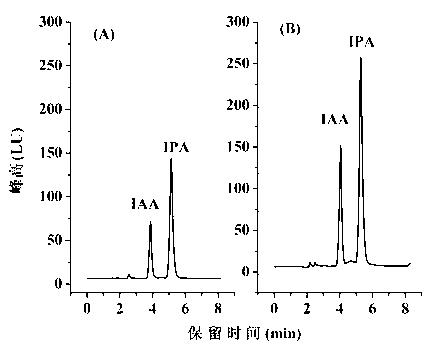

Image

Examples

Embodiment Construction

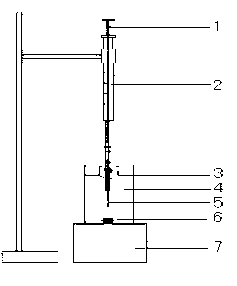

[0035] Prepare IAA-MISPME coating by content of the present invention:

[0036] a) Quartz fiber pretreatment: Take a quartz fiber about 20 cm long, soak one end in acetone for 5 minutes, peel off the polyimide coating on the outer layer, and wash with secondary water, 1.0 mol / L NaOH, and secondary water successively. , soaked in 1 mol / L HCl, washed, dried, put the quartz fiber into 10% (v / v) γ-MAPS acetone solution for silanization treatment for 2 h, rinsed with methanol after taking it out, blown dry with nitrogen, and set aside .

[0037] b) Preparation of pre-polymerization solution: use IAA as a template molecule, add an appropriate amount of 4-vinylpyridine (functional monomer) and acetonitrile (porogen) and mix well, leave at room temperature for 12 h, then add trimethylolpropane trimethacrylic acid Esters (crosslinking agent) and azobisisobutyronitrile (initiator), ultrasonically mixed, nitrogen and oxygen removed to obtain a pre-polymerization solution.

[0038] c) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com