New technology for producing acrylamide by using ceramic membrane bioreactor

A technology of bioreactor and acrylamide, applied in the separation/purification of carboxylic acid amide, organic chemistry, fermentation, etc., to achieve the effects of good corrosion resistance, reduced production cost, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

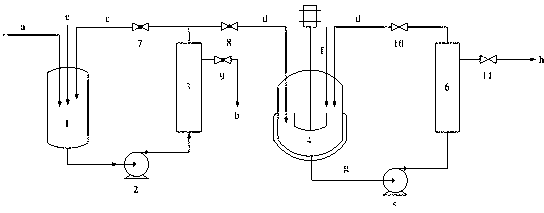

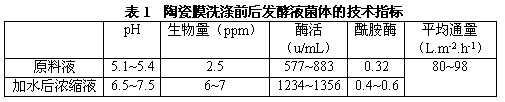

[0043] like figure 1 As shown, a process for treating acrylamide fermentation liquid cells includes the following steps: pour 150kg of bacterial cell fermentation liquid (pH=5.4, wet cell content 5.8%) nitrile hydratase cell fermentation liquid a into the fermentation liquid bacteria Body water washing tank 1, and the nitrile hydratase thalline fermentation liquid a after the booster pump 2 pressurization enters the ceramic microfiltration membrane filter 3, opens the spherical valve 7, closes the spherical valve 8, and controls the temperature below 10°C. The operating pressure is 0.15MPa and the membrane surface flow rate is 4.6m / s, and the concentrated liquid c flowing out of the ceramic microfiltration membrane filter 3 is output to the fermented liquid bacteria washing tank 1, and the permeate of the ceramic microfiltration membrane filter 3 b discharge. When the concentration multiple reaches 6, add dialysis water e in the ceramic microfiltration membrane filter 3 to ca...

Embodiment 2

[0047] like figure 1 As shown, a process for treating acrylamide fermentation liquid cells includes the following steps: pour 180kg of nitrile hydratase bacterial cell fermentation liquid a containing bacterial cell fermentation liquid (pH=5.1, wet cell content 6%) into the fermentation liquid In the bacterial cell washing tank 1, the nitrile hydratase bacterial cell fermentation liquid a pressurized by the booster pump 2 enters the ceramic microfiltration membrane filter 3, opens the spherical valve 7, closes the spherical valve 8, and controls the temperature below 10°C , the operating pressure is 0.2MPa and the membrane surface flow velocity is 4.8m / s, carry out circulation concentration filtration, the concentrate c that the ceramic microfiltration membrane filter 3 flows out outputs the fermented liquid bacterium washing tank 1, the infiltration of the ceramic microfiltration membrane filter 3 Liquid b is discharged. When the concentration ratio reaches 7, add dialysis w...

Embodiment 3

[0051] like figure 1 As shown, a process for treating acrylamide fermentation liquid cells includes the following steps: pour 220kg of nitrile hydratase bacterial cell fermentation liquid a containing bacterial cell fermentation liquid (pH=5.4, wet cell content 6%) into the fermentation liquid In the bacterial cell washing tank 1, the nitrile hydratase bacterial cell fermentation liquid a pressurized by the booster pump 2 enters the ceramic microfiltration membrane filter 3, opens the spherical valve 7, closes the spherical valve 8, and controls the temperature below 10°C , the operating pressure is 0.25MPa and the membrane surface flow velocity is 6m / s, and the concentrated liquid c that flows out from the ceramic microfiltration membrane filter 3 is output to the fermented liquid bacterium washing tank 1, and the permeate from the ceramic microfiltration membrane filter 3 is 6m / s. b discharge. When the concentration ratio reaches 8, add dialysis water e in the ceramic micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com