Polysilicon active layer-containing thin film transistor, manufacturing method thereof and array substrate

A technology of thin film transistors and array substrates, which is applied in the field of thin film transistors containing polysilicon active layers, can solve the problems of large leakage current and high nickel content of TFT, and achieve the effect of reducing leakage current and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

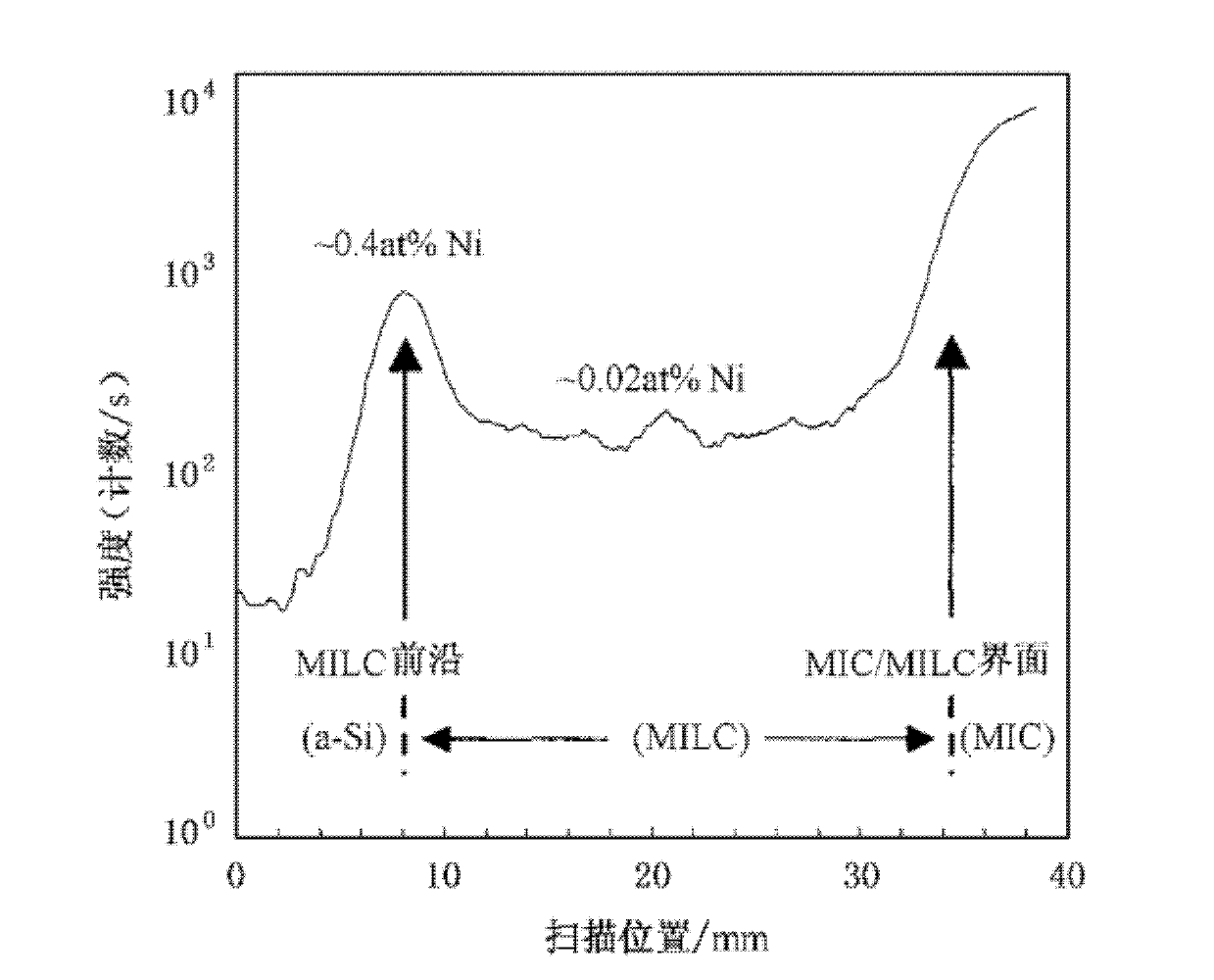

[0023] image 3 It is a flowchart of a method for manufacturing a thin film transistor containing a polysilicon active layer according to an embodiment of the present invention, referring to image 3 , including the following steps:

[0024] Step 301: depositing a buffer layer on the substrate;

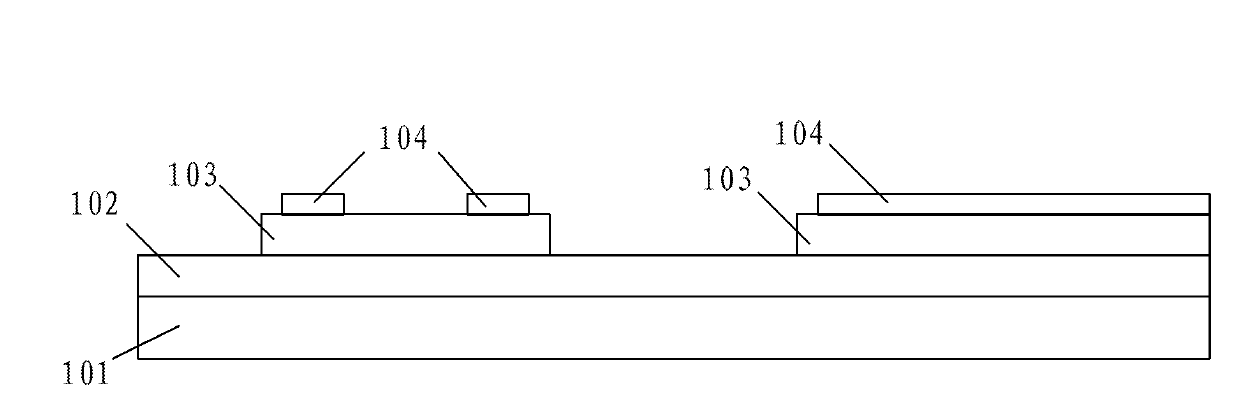

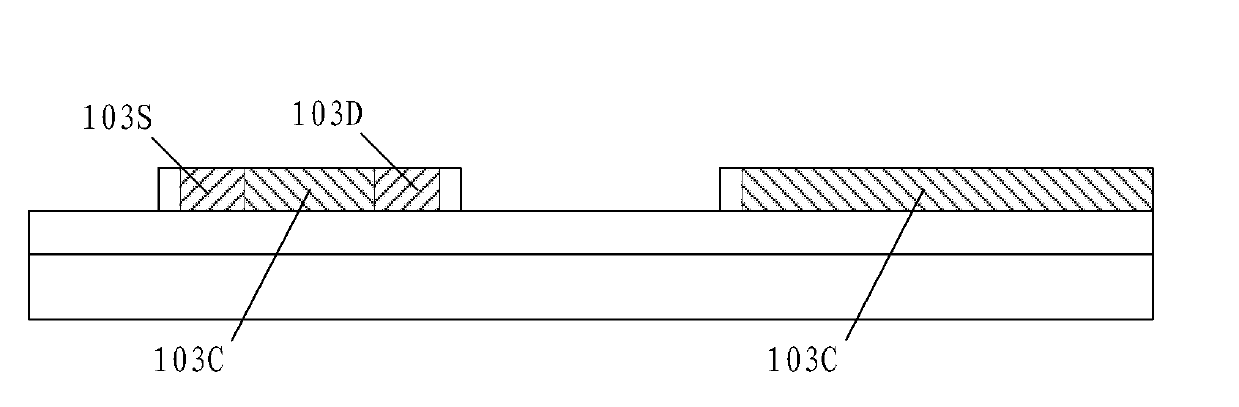

[0025] refer to Figure 4A , on a transparent substrate 401 such as pre-cleaned glass, PECVD (plasma enhanced chemical vapor deposition), LPCVD (low pressure chemical vapor deposition), APCVD (atmospheric pressure chemical vapor deposition), ECR-CVD (electron cyclotron resonance chemical vapor deposition) ) or sputtering to form the buffer layer 402 to prevent the impurities contained in the glass from diffusing into the active layer and prevent the infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com