Double-pressure submerged arc furnace waste heat boiler with mechanical brush ash-removing device

An ash cleaning device and waste heat boiler technology, applied in the field of waste heat boilers, can solve the problems of uneven distribution of steel balls, reduced heat exchange effect, forming large heating surfaces, etc., achieving simple operation, saving operating costs, and improving ash cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

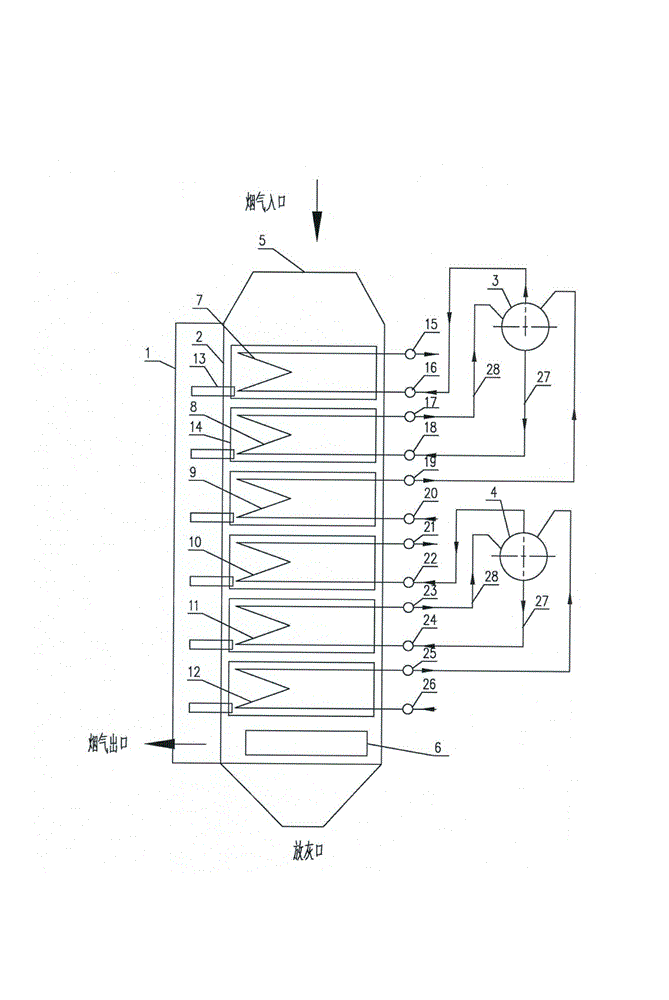

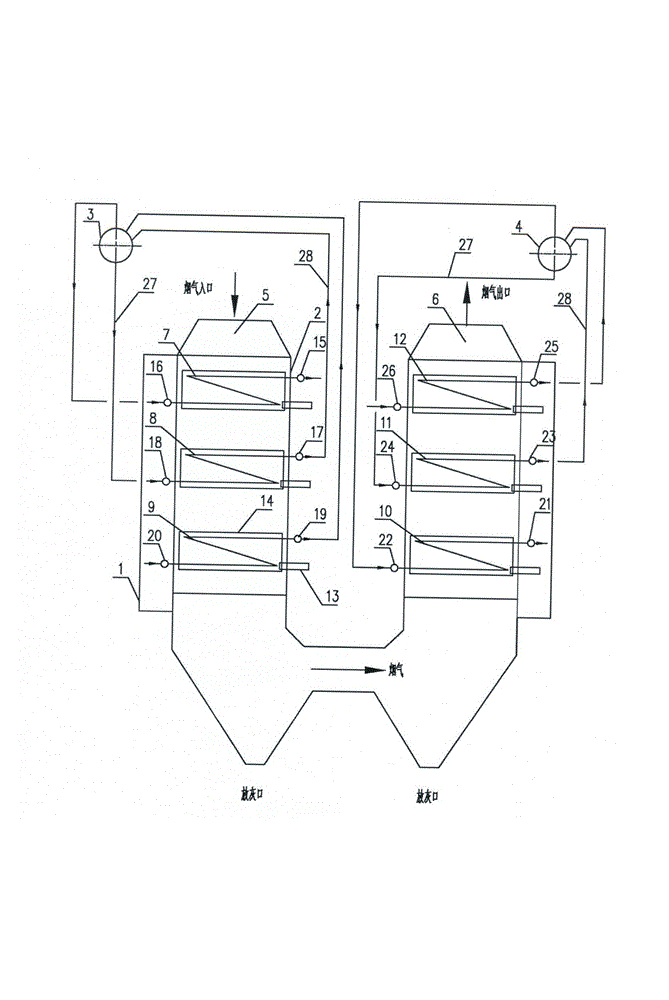

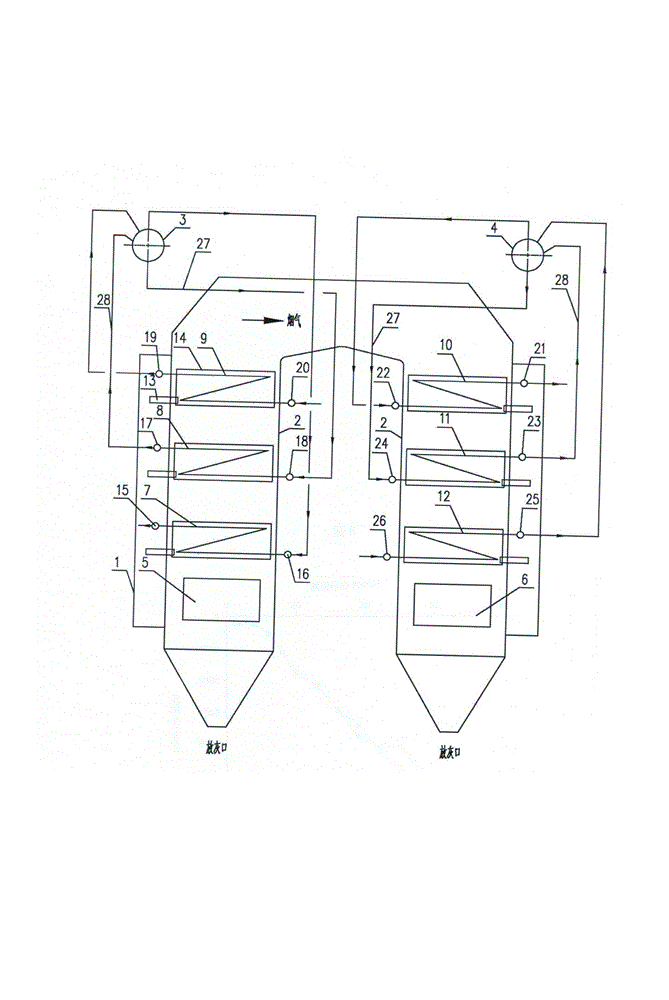

[0031] exist figure 1In the schematic diagram of the front view of a double-pressure "I" type submerged arc furnace waste heat boiler with a mechanical brush cleaning device shown, the support 1 is a frame composed of columns and beams, and a secondary medium pressure is installed on the support. The drum 3 and the low-pressure drum 4 are equipped with a convection shaft 2 inside the support, and the shell of the convection shaft is the furnace wall, that is, rock wool insulation material is placed between the inner and outer guard plates, and the inner guard plate faces the side of the well cavity. Refractory concrete. One end of the casing of the convection shaft is connected to the flue gas inlet 5 , and the other end of the casing is connected to the flue gas outlet 6 . In the convection shaft, from the flue gas inlet to the flue gas outlet, there are sub-medium pressure superheater 7, sub-medium pressure evaporator 8, sub-medium pressure economizer 9, low-pressure superh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com