Biodegradable zinc (or zinc alloy) and porous biphase calcium phosphate composite material and preparation method thereof

A technology of biphasic calcium phosphate and porous calcium phosphate, applied in medical science, prostheses, etc., can solve the problems of limitation, sudden mass release, low toughness, etc., to maintain connectivity, improve biocompatibility, and good mechanical stability The effect of sex and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

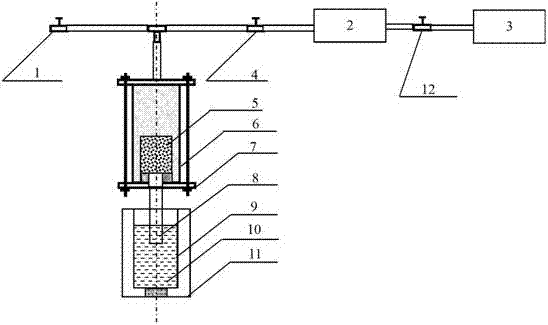

Method used

Image

Examples

Embodiment 1

[0025] Preparation of biodegradable zinc and biphasic calcium phosphate composites with 95% porosity and 10% HA, the steps are as follows:

[0026] (1) Preparation of porous biphasic calcium phosphate (β-TCP / HA) preform containing 10% HA;

[0027] ① Preparation of HA, β-TCP powder. a 250g calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and 100g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) were dissolved in deionized water to form 0.4mol / l and 0.3mol / l aqueous solutions; b. 0.4mol / l calcium nitrate aqueous solution was heated to 40°C in a constant temperature magnetic stirrer, and then 0.3mol / l phosphoric acid Diammonium hydrogen aqueous solution is dripped at a rate of (2-3) ml / min, and the pH value of the reaction solution is adjusted by ammonia water (HA: pH is about 10; β-TCP: pH is about 5.5-6); c according to Ca / P=1.48 After the titration, continue to stir at 40°C for half an hour, let it stand still, and settle naturally for 24h; c. Wash and centrifuge the precipitate, ...

Embodiment 2

[0039] Preparation of biodegradable Zn-Mg alloy and biphasic calcium phosphate composite with 95% porosity and 35% HA. The steps are as follows:

[0040] (1) Prepare a porous biphasic calcium phosphate preform containing 35% HA in the same manner as in Example 1. The difference is that when preparing HA and β-TCP slurry, the amount of HA powder added is 17.5 g, and the amount of β-TCP powder added is 32.5 g.

[0041] (2) Suction-cast Zn-3Mg alloy according to the same method as in Example 1, the difference is that the molten alloy is a Zn-3Mg alloy (that is, the weight percentage of Mg is 3%, and the rest is Zn), and at 650°C Keep warm and set aside.

[0042] From the observation of the structure of the composite material, it can be seen that the interface between the dual-phase calcium phosphate and the Zn-3Mg alloy is well combined, and the structure of the composite material is compact, while maintaining the respective connectivity of the dual-phase calcium phosphate and ...

Embodiment 3

[0044] Biphasic calcium phosphate composites with biodegradable zinc-yttrium alloy and 90% porosity and 50% HA were prepared. The steps are as follows:

[0045] (1) Prepare a porous biphasic calcium phosphate preform containing 50% HA in the same manner as in Example 1. The difference is that when preparing HA and β-TCP slurry, the addition amount of HA powder is 25g, and the addition amount of β-TCP powder is 25g. When preparing the porous biphasic calcium phosphate preform, the polyurethane foam was dipped and extruded four times in HA and β-TCP slurry.

[0046] (2) Suction-cast Zn-2Y alloy according to the same method as in Example 1, the difference is that the molten alloy is a Zn-2Y alloy (that is, the weight percentage of Y is 2%, and the rest is Zn), and at 600 ° C Keep warm and set aside.

[0047] From the observation of the structure of the composite material, it can be seen that the interface of the biphasic calcium phosphate and the Zn-2Y alloy is well combined, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com