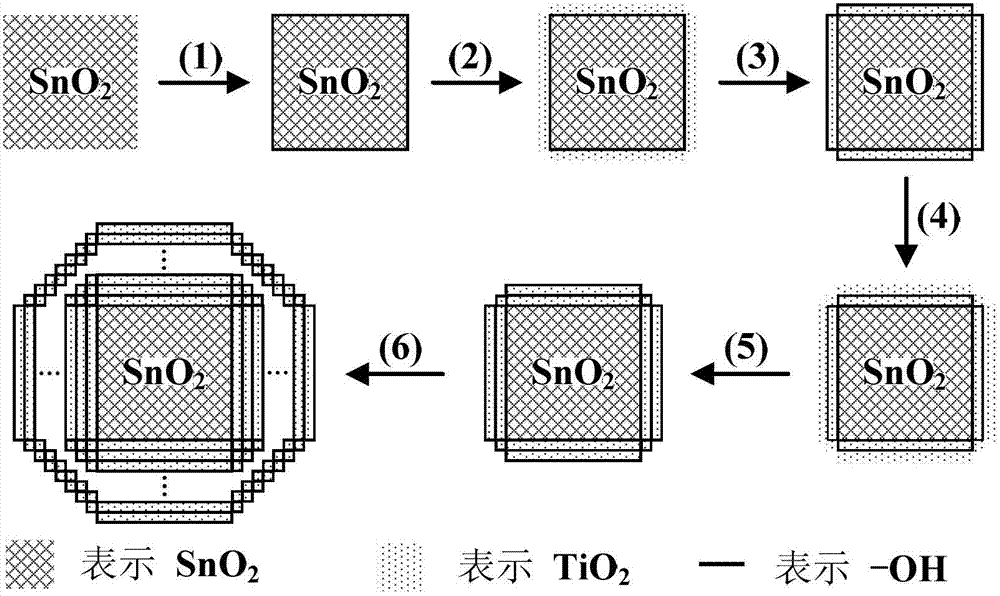

Preparation method of stannic oxide-titanium dioxide core-shell nano-structure

A technology of titanium dioxide and tin dioxide, which is applied in the field of preparation of tin dioxide-titanium dioxide core-shell structure nanocomposites, can solve the problems of low quantum efficiency, achieve simple process, uniform size distribution of core-shell structure, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

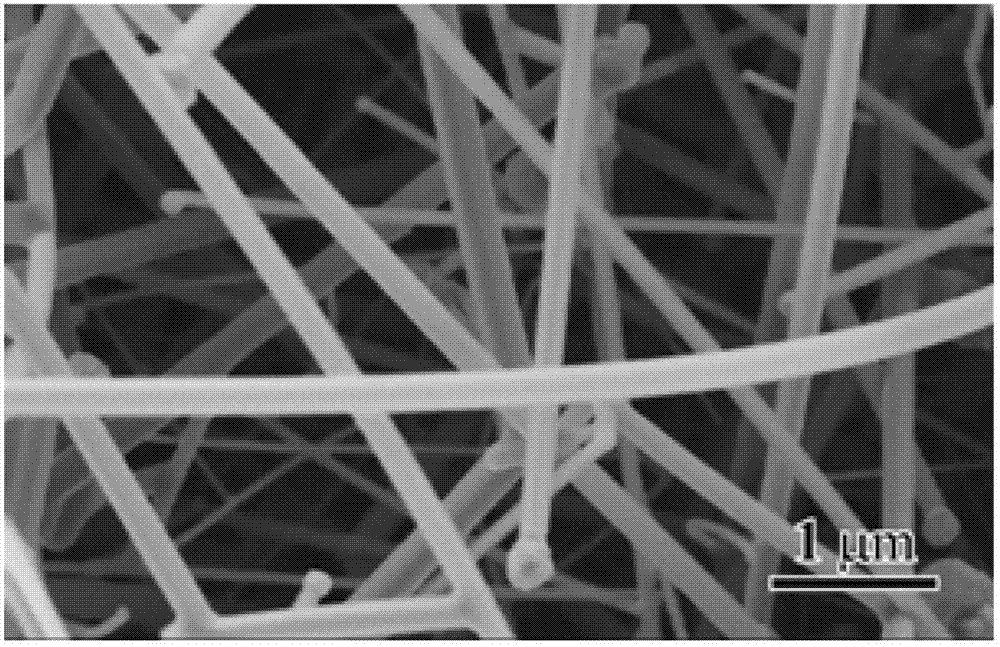

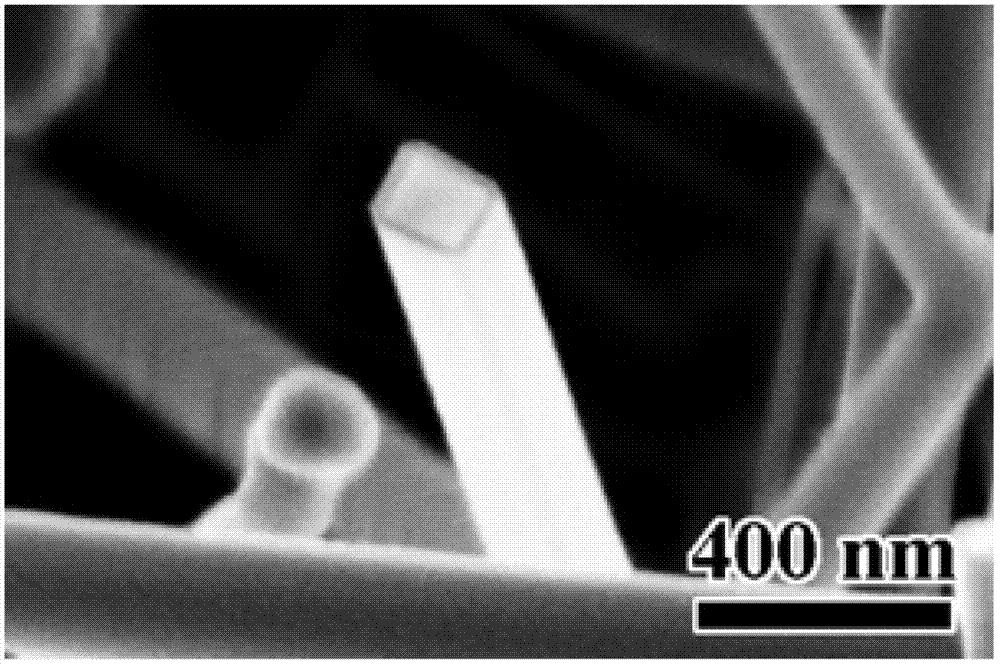

[0024] Example 1: Using silicon as a reaction substrate and gold as a catalyst to prepare a tin dioxide-titania core-shell structure.

[0025] First, the silicon substrate was ultrasonically cleaned in deionized water, acetone and ethanol for 30 minutes respectively, and the surface of the silicon substrate was blown dry with high-purity nitrogen; then the silicon substrate was placed in a vacuum sputtering apparatus, and about A nano-gold granular layer with a thickness of 90 nanometers; then place the porcelain boat filled with tin powder in the central high-temperature heating zone of the CVD device, place the silicon substrate at about 10 cm from the lower air outlet of the porcelain boat, and use a vacuum pump to reduce the vacuum degree of the CVD device. Adjust it below 5mTorr; moreover, raise the temperature of the high-temperature heating zone in the center of the CVD device to 800°C within 40 minutes, keep it at 800°C for 30 minutes and feed oxygen at a flow rate of 1...

Embodiment 2

[0026] Example 2: Using silicon dioxide as a reaction substrate and platinum as a catalyst to prepare a tin dioxide-titania core-shell structure.

[0027] First, the silicon dioxide substrate was ultrasonically cleaned in deionized water, acetone and ethanol for 30 minutes respectively, and the surface of the silicon dioxide substrate was blown dry with high-purity argon; then the silicon dioxide substrate was placed in a vacuum sputtering apparatus, and the The silicon dioxide surface is sputter-coated with a nano-platinum granular layer with a thickness of about 90 nanometers; then the porcelain boat filled with tin powder is placed in the central high-temperature heating area of the CVD device, and the silicon dioxide substrate is placed about 10 cm below the air outlet of the porcelain boat At the place, use a vacuum pump to adjust the vacuum degree of the CVD device below 5mTorr; moreover, raise the temperature of the high-temperature heating zone in the center of the CV...

Embodiment 3

[0028] Example 3: Using silicon nitride as a reaction substrate and platinum as a catalyst to prepare a tin dioxide-titania core-shell structure.

[0029] First, the silicon nitride substrate was ultrasonically cleaned in deionized water, acetone and ethanol for 30 minutes respectively, and the surface of the silicon nitride substrate was blown dry with high-purity nitrogen; The surface of SiO is sputter-coated with a nano-gold granular layer with a thickness of about 90 nanometers; then the porcelain boat filled with tin powder is placed in the central high-temperature heating zone of the CVD device, and the silicon nitride substrate is placed about 10 cm below the air outlet of the porcelain boat , use a vacuum pump to adjust the vacuum degree of the CVD device below 5mTorr; moreover, raise the temperature of the high-temperature heating zone in the center of the CVD device to 800°C within 40 minutes, keep it at a high temperature of 800°C for 30 minutes and feed in oxygen at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com