Method for removing carbon, nitrogen and sulfur in waste water

A waste water, carbon and nitrogen technology, applied in the direction of chemical instruments and methods, waste fuel, oxidized water/sewage treatment, etc., can solve the problems of high cost of waste water treatment, secondary pollution, a large number of chemical agents, etc., to improve biodegradability, The effluent water quality meets the standard and the treatment effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

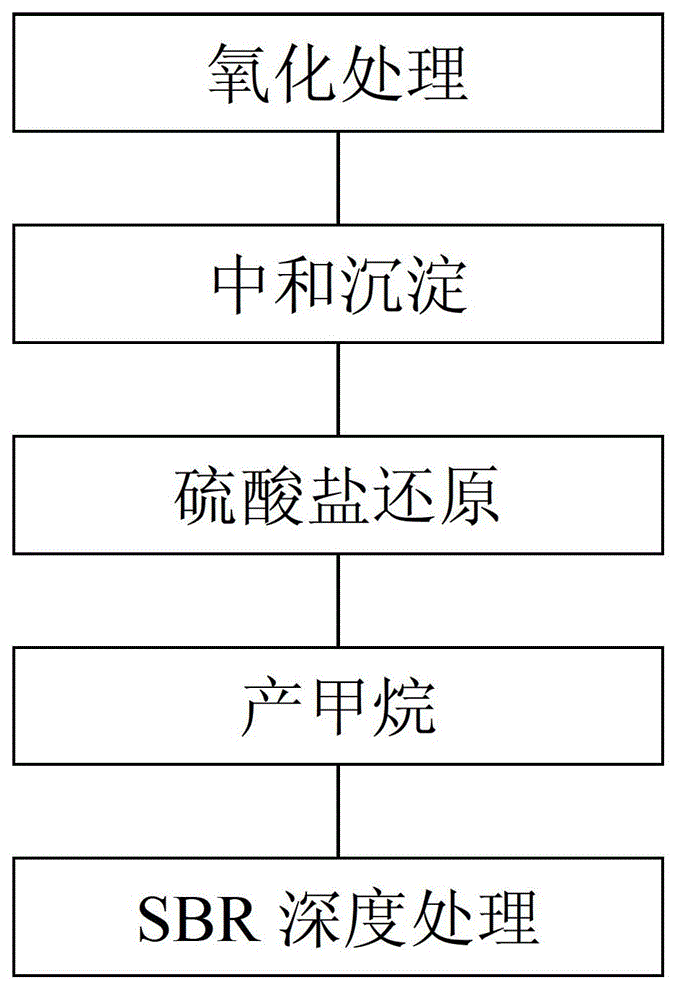

Method used

Image

Examples

Embodiment 1

[0020] The water quality parameters of the chemical fiber wastewater in this example are shown in Table 1.

[0021] project

scope

average

Chemical oxygen demand COD / (mg / L mg / L)

4316-4910

4636

Biochemical Oxygen Demand (BOD) 5 / (mg / L mg / L)

316-431

366

Biochemical Oxygen Demand / Chemical Oxygen Demand BOD 5 / COD

0.06-0.10

0.08

Ammonia nitrogen / (mg / L mg / L)

81-97

91

Sulphate / (mg / L mg / L)

3961-4366

4187

Nitrate nitrogen / (mg / L mg / L)

2.8-4.7

4.1

Total Nitrogen / (mg / L mg / L)

118-219

179

pH

2.8-3.5

3.1

[0022](1) Add 500 mg / L of ferrous sulfate and 800 mg / L of hydrogen peroxide (concentration: 30%) to the waste water, and control the speed of the mixer at 150 rpm to ensure that the waste water and the reaction reagent are mixed evenly. After 25 minutes of hydraulic retention time, the primary effluent was obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com