Heat conduction nylon composite material and preparation method thereof

A technology of thermally conductive composite material and nylon composite material, which is applied in the field of thermally conductive materials, can solve problems such as difficulty in meeting the use performance, limit the wide application of thermally conductive plastics, etc., and achieve the effects of being beneficial to stability, improving physical and mechanical properties, and having a simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of heat-conducting nylon composite material, the mass percentage composition comprising component and each component is as follows:

[0031]

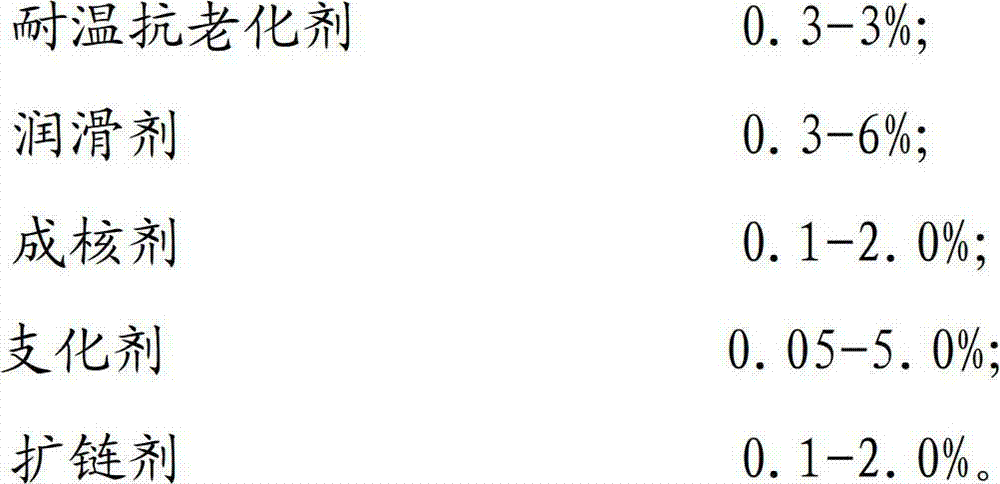

[0032] The nylon is selected from PA6; the compatibilizer is maleic anhydride grafted ethylene-1-octene copolymer (POE-g-MAH); the high thermal conductivity fiber is carbon fiber; the high thermal conductivity filler is graphene and a mixture of nano-alumina; the auxiliary agent includes a temperature-resistant anti-aging agent, a lubricant, a nucleating agent, a branching agent and a chain extender. The mass percent of each component of the auxiliary agent in the total amount of the heat-conducting nylon composite material is:

[0033]

[0034] The temperature-resistant anti-aging agent is a mixture of hindered phenolic antioxidant and copper chloride.

[0035] Described lubricant is calcium stearate.

[0036] The nucleating agent is talcum powder.

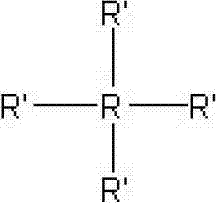

[0037] Described branching agent chemical structural formula is...

Embodiment 2

[0042] A kind of heat-conducting nylon composite material, the mass percentage composition comprising component and each component is as follows:

[0043]

[0044] The nylon is selected from the mixture of PA6 and PA66; the compatibilizer is a maleic anhydride grafted thermoplastic elastomer (TPE-g-MAH) and a maleic anhydride grafted ethylene-propylene-cyclopentadiene terpolymer (EPDM-g-MAH) mixture; the high thermal conductivity fiber is carbon nanotube; the high thermal conductivity filler is a mixture of aluminum nitride and silicon carbide; the additive contains temperature resistance Aging agent, lubricant, nucleating agent, branching agent and chain extender.

[0045] The mass percent of each component of the auxiliary agent in the total amount of the heat-conducting nylon composite material is:

[0046]

[0047] The temperature-resistant anti-aging agent is a phosphite antioxidant.

[0048] The lubricant is a mixture of ethylene bis stearic acid amide and silico...

Embodiment 3

[0053] A kind of heat-conducting nylon composite material, the mass percentage composition comprising component and each component is as follows:

[0054]

[0055] The nylon is selected from a mixture of PA612 and PA1010; the compatibilizer is maleic anhydride grafted ethylene-propylene-cyclopentadiene terpolymer (EPDM-g-MAH); The high thermal conductivity fiber is carbon fiber; the high thermal conductivity filler is a mixture of boron nitride and scaly high thermal conductivity carbon powder; agent.

[0056] The mass percent of each component of the auxiliary agent in the total amount of the heat-conducting nylon composite material is:

[0057]

[0058] The temperature-resistant anti-aging agent is an alkali metal halide.

[0059]Described lubricant is the mixture of calcium stearate and ethylene bis stearic acid amide.

[0060] The nucleating agent is selected from talcum powder.

[0061] The branching agent is trihydroxypropylene oxide.

[0062] The chain extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com