Mesoporous zirconia nano material and method for preparing same

A technology of mesoporous zirconia and nanomaterials, applied in the direction of zirconia and nanotechnology, can solve the problems of poor thermal stability, irregular pore size distribution, and small specific surface area of mesoporous zirconia, and achieve suitable for large-scale production and low cost. Effect of low cost and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

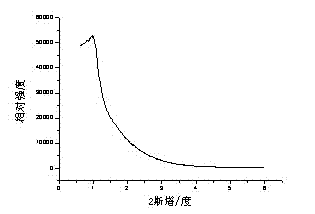

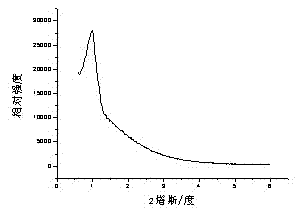

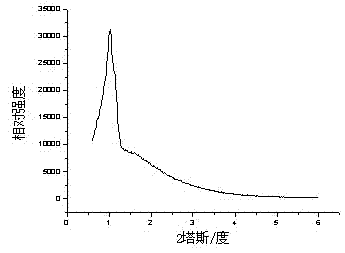

Image

Examples

Embodiment 1

[0047] A method for preparing a mesoporous zirconia nanomaterial, comprising the following steps:

[0048] (1), add 0.5g of EO 106 PO 70 EO 106 Disperse in 5g of ethanol and stir at room temperature for 5min, then add 0.05g of ZrOCl 2 , stirred at room temperature for 5min, then added 0.05g tetraethyl orthosilicate and 0.25g phenolic resin in turn, stirred at room temperature for 20min until a homogeneous transparent solution was formed,

[0049] Put the homogeneous transparent solution obtained above into a crystallization dish, put it in a fume hood overnight, then put it into a blast drying oven, control the temperature at 50°C, and take 24 hours to obtain the organic / inorganic zirconia composite. dry film;

[0050] (2) Put the dry film of the organic / inorganic zirconia composite obtained in step (1) in a tube furnace, heat up to 700°C at a rate of 1°C / min under a nitrogen atmosphere, and bake at this temperature After 20h, it was naturally cooled to room temperature t...

Embodiment 2

[0062] A method for preparing a mesoporous zirconia nanomaterial, comprising the following steps:

[0063] (1), add 0.5g of EO 20 PO 70 EO 20 Disperse in 25g of deionized water and stir for 5min at room temperature, then add 2.5g of zirconium tetrachloride, stir for 5min at room temperature, then add 5g of tetramethyl orthosilicate and 25g of sucrose in turn, and stir for 20min at room temperature until it becomes homogeneous and transparent solution;

[0064] Put the homogeneous transparent solution obtained above into a crystallization dish, put it in a fume hood overnight, and then put it into a blast drying oven to control the temperature at 150°C for 24 hours to obtain the dryness of the organic / inorganic zirconia composite. film;

[0065] (2) Put the dry film of the organic / inorganic zirconia composite obtained in step (1) in a tube furnace, heat up to 1100°C at a rate of 1°C / min under a nitrogen atmosphere, and bake at this temperature After 6h, naturally cool to r...

Embodiment 3

[0070] A method for preparing a mesoporous zirconia nanomaterial, comprising the following steps:

[0071] (1), add 0.5g of EO 132 PO 60 EO 132 Disperse in 6g of methanol, stir at room temperature for 5min, then add 0.2g of zirconium nitrate, stir at room temperature for 5min, then add 0.1g of tetrapropyl orthosilicate and 2.5g of furfuryl alcohol resin in turn, stir at room temperature for 30min until homogeneous clear solution;

[0072] Put the homogeneous transparent solution obtained above into a crystallization dish, put it in a fume hood overnight, then put it into a blast drying oven, control the temperature at 60°C, and keep the time for 24h to obtain an organic / inorganic zirconia composite dry film;

[0073] (2) Put the dry film of the organic / inorganic zirconia composite obtained in step (1) in a tube furnace, heat up to 800°C at a rate of 1°C / min in a nitrogen atmosphere, and bake at this temperature After 6h, it was naturally cooled to room temperature to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com