Green and environmental protection paper and its manufacturing method

A technology of green environmental protection and manufacturing method, applied in the field of mixed environmentally friendly paper, can solve the problems of inconvenient use, high cost of mechanical equipment, too soft, etc., to enhance adhesion and stiffness, reduce production costs, and increase ductility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

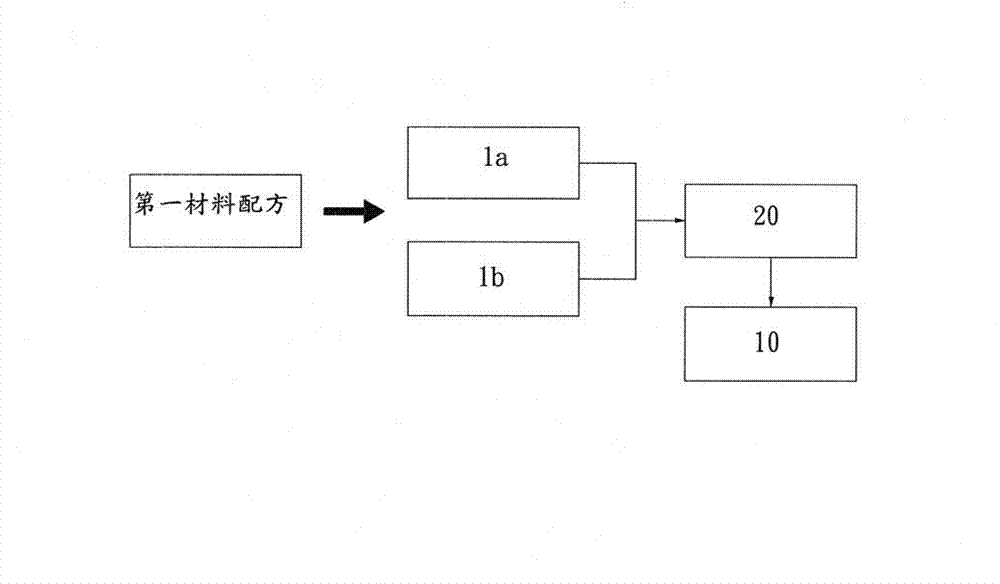

[0061] Please see figure 1 and Figure 7 As shown, the present invention is a specific embodiment to achieve the aforementioned first purpose. The environmentally friendly paper 10 is produced by mixing the first material formula and using calendering molding technology. The paper thickness of the finished environmentally friendly paper 10 is between 50 and 700 μm between. The first material formula includes a polymer material 1a and an inorganic material 1b, wherein the polymer material 1a accounts for 15-25% by weight, the inorganic material 1b accounts for 75-85% by weight, and the average particle size of the inorganic material 1b is between 1 μm ~5μm, and the finished product of environmentally friendly paper 10 with a smooth surface can be obtained. As for the specific example of the polymer material 1a, it can be at least one plastic material in polypropylene (PP), polyethylene (PE) or poly lactic acid (Poly Lactic Acid, PLA), which is non-toxic and decomposable. The...

Embodiment 2

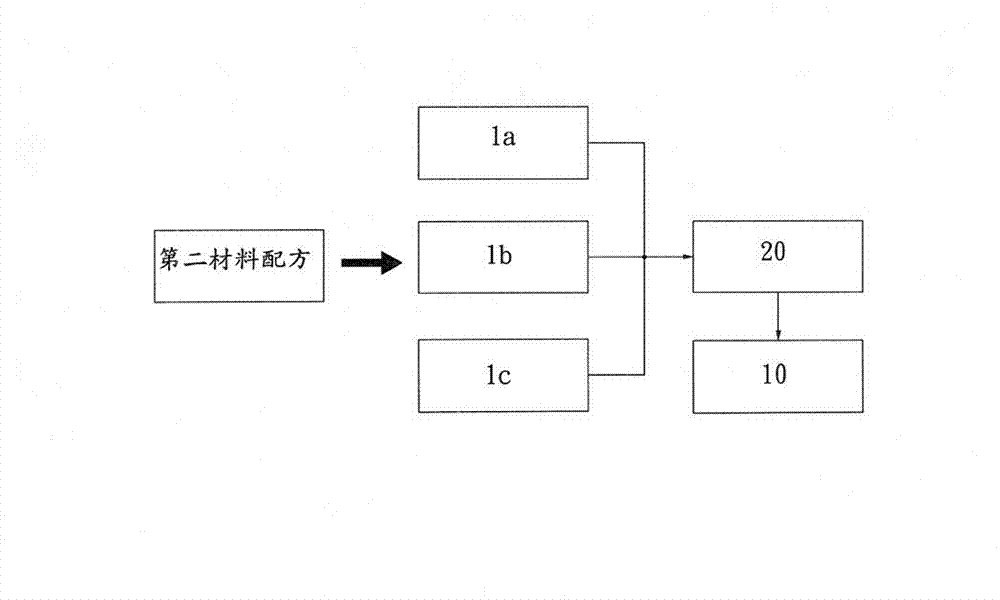

[0064] Please see figure 2 and Figure 7 As shown, the present invention is a specific embodiment to achieve the aforementioned second purpose. The environmentally friendly paper 10 is produced by kneading the second material formula and using calendering molding technology, mainly adding organic materials to replace part of the polymer materials. , so as to reduce the production cost and increase the stiffness of the paper, so that the produced environmentally friendly paper is closer to the texture of wood pulp paper. The paper thickness of the environmentally friendly paper 10 produced in this embodiment of the present invention is about 50 μm, so as to meet more popular demands. Moreover, the environmentally friendly paper 10 of the present invention can be decomposed naturally by water or sunlight due to the addition of organic materials, or the decomposition speed of the environmentally friendly paper 10 can be accelerated by organisms (such as bacteria).

[0065] The...

Embodiment 3

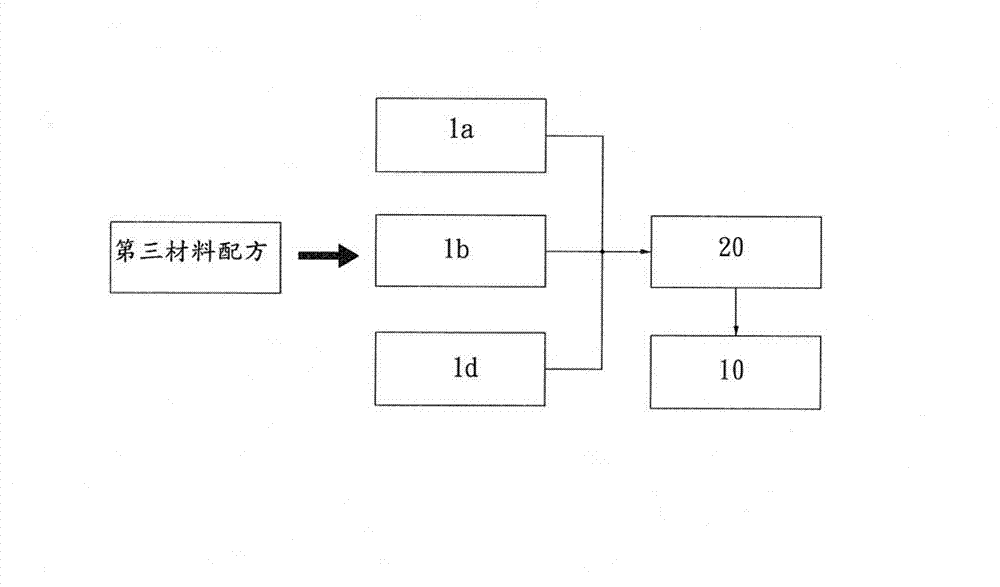

[0068] Please see image 3 and Figure 7 As shown, the present invention is a specific embodiment for achieving the aforementioned third purpose. Its environmentally friendly paper 10 is manufactured by mixing the third material formula and utilizing calendering molding technology. The third material formula mainly includes polymer material 1a, inorganic Material 1b and foaming agent 1d are used as packaging cushioning materials by molding, thereby replacing traditional packaging paper, cartons, shipping filling paper or corrugated paper, and can reduce weight and reduce production costs, and environmentally friendly paper 10 finished paper The thickness is about 700 μm. In the experimental example of the present invention, the third material formula includes a polymer material, an inorganic material, an organic material and a foaming agent, wherein the weight percentage of the polymer material is 5-25%, and the weight percentage of the inorganic material 1b is 35-84%, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com