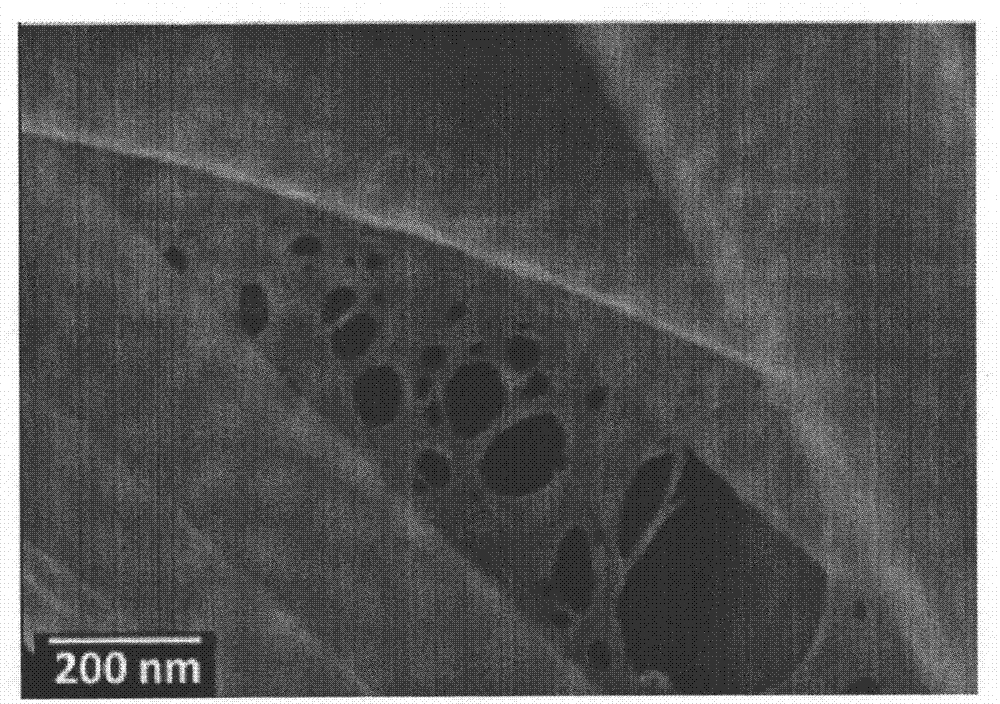

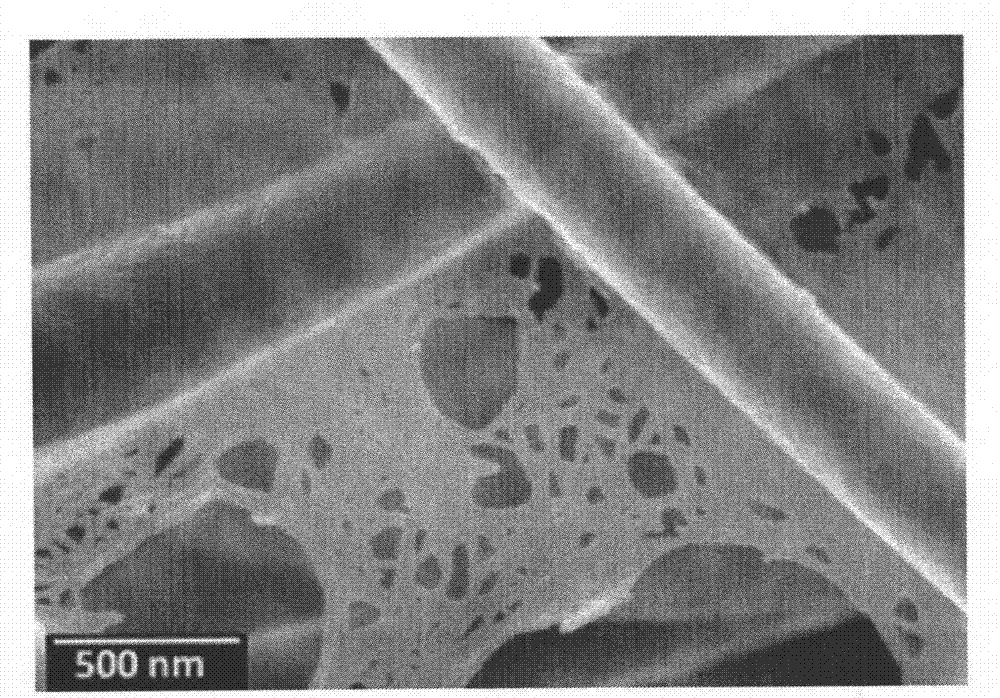

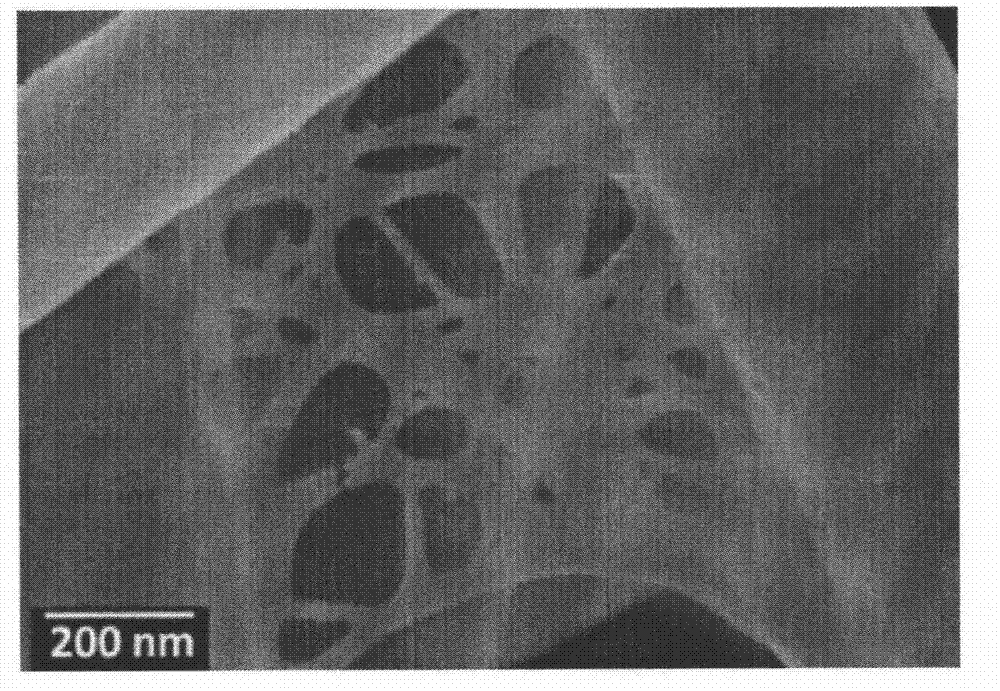

Preparation method of porous network structure fiber membrane of nano cellulose/silicon dioxide

A technology of nanocellulose and cellulose fibers, which is applied in textiles, papermaking, non-woven fabrics and other directions to achieve the effects of improving mechanical properties, good filtering effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Under the condition of 80℃ water bath temperature, soak 1g cotton linters in a stirred tank containing 50g of 10% sodium hydroxide solution, the stirring speed is 100rpm, the stirring time is 30min, and the water is washed until it is neutral. Drying in a vacuum oven with a drying temperature of 60°C and a drying time of 12 hours to obtain alkali-treated cotton fibers;

[0042] (2) Under the condition of a water bath temperature of 80℃, add the alkali-treated cotton fiber to the stirred tank containing dimethyl sulfoxide, the solid-liquid mass ratio of cotton fiber to dimethyl sulfoxide is 1:20, stir Rotation speed is 100rpm, stirring time is 6h, filtered, and the residual dimethyl sulfoxide is eluted with distilled water, and dried in a vacuum oven at a drying temperature of 80°C and a drying time of 12h to obtain pretreated cotton fibers;

[0043] (3) Under the condition of 4℃ water bath temperature, add 1g of pretreated cotton fiber to a stirred tank containing 0.001g...

Embodiment 2

[0054] (1) Under the condition of 60℃ water bath temperature, soak 3g of ramie fiber powder in a stirred tank containing 100g of 15% sodium hydroxide solution, the stirring speed is 200rpm, the stirring time is 100min, and the water is washed until it is neutral. Drying in a vacuum oven with a drying temperature of 60°C and a drying time of 8 hours to obtain alkali-treated ramie fiber powder;

[0055] (2) Add the alkali-treated ramie fiber powder to the stirred tank containing dimethyl sulfoxide under the condition of a water bath temperature of 50°C. The solid-liquid mass ratio of ramie fiber powder to dimethyl sulfoxide is 1:40 , The stirring speed is 500rpm, the stirring time is 5h, filtered, the residual dimethyl sulfoxide is eluted with distilled water, and dried in a vacuum oven at a drying temperature of 60℃ and a drying time of 12h to obtain pretreated ramie fiber powder ;

[0056] (3) Add 1g of pretreated ramie fiber powder to a stirred tank containing 0.001g TEMPO, 5g so...

Embodiment 3

[0067] (1) Under the condition of 40℃ water bath temperature, immerse 1g of wood pulp fiber powder in a stirred tank containing 200g of 10% sodium hydroxide solution, the stirring speed is 200rpm, the stirring time is 100min, and the water is washed until neutral. , Drying in a vacuum oven with a drying temperature of 70°C and a drying time of 10 hours to obtain alkali-treated wood pulp fiber powder;

[0068] (2) Under the condition of 50℃ water bath temperature, add the alkali-treated wood pulp fiber powder to the stirred tank containing dimethyl sulfoxide. The solid-liquid mass ratio of wood pulp fiber powder to dimethyl sulfoxide is 1 :30, stirring speed of 500rpm, stirring time of 6h, filtering, eluting the residual dimethyl sulfoxide with distilled water, and drying in a vacuum oven at a drying temperature of 65℃ and a drying time of 10h to obtain pretreated wood Pulp fiber powder;

[0069] (3) Add 1g of pretreated wood pulp fiber powder to a stirred tank containing 0.02g TEM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com