Ultrafast laser pulse method for forming nanopores with diameters of 2 nanometers

A metal nano and ultrafast laser technology, applied in the field of nanomaterials, can solve the problems of inability to prepare metal nanopore structures and nanostructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

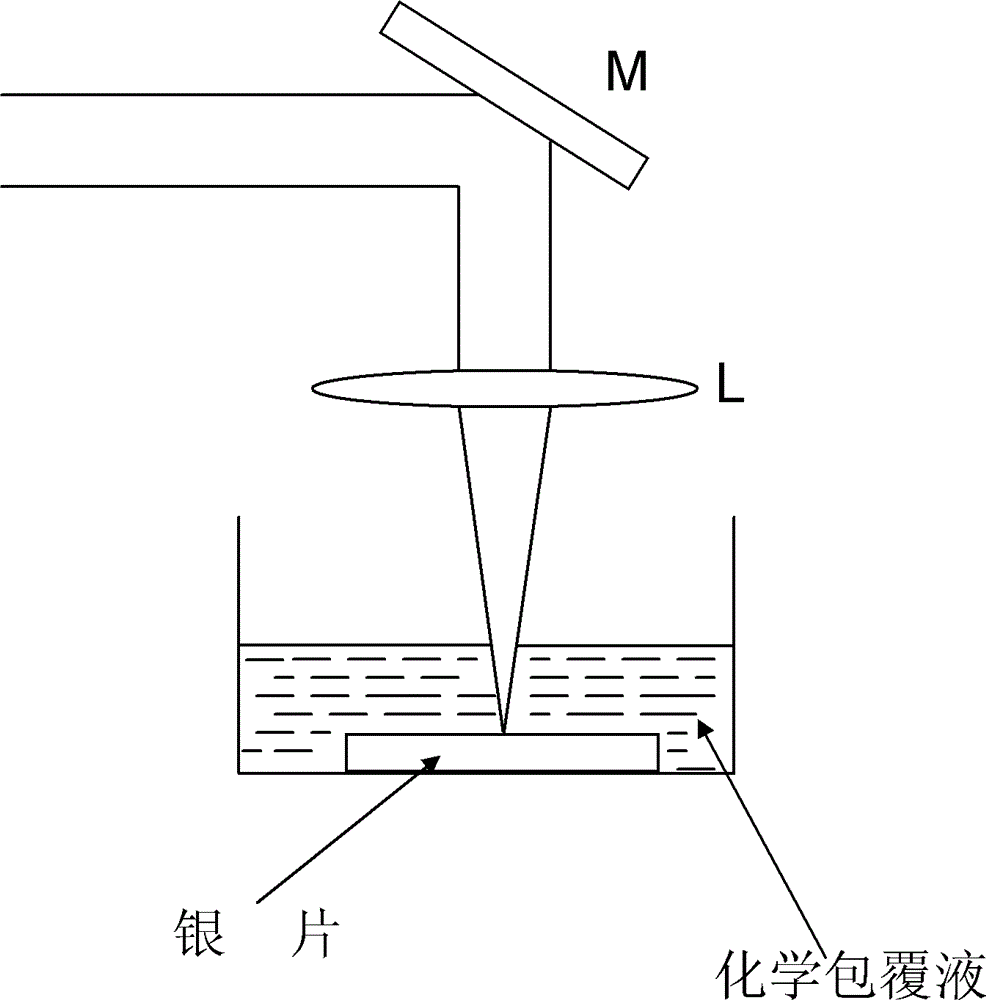

Method used

Image

Examples

Embodiment 1

[0041]First accurately weigh the PVP powder equivalent to the sodium citrate crystal of the corresponding quality of 0.3mmol and the PVP powder of the corresponding quality of 0.1mmol with an electronic balance, and the deionized water of 11.03mL is used to dissolve the two kinds of medicaments in a beaker to form a uniform mixed solution ( The volume of the mixed solution can be more, but to ensure that the concentration of the two reagents is constant), that is, the chemical coating solution.

[0042] In order to ensure the consistency of the silver sheet target used in the ablation experiment, before each experiment, it was washed three times with deionized water, then rinsed with absolute ethanol, and finally dried for use. In order to ensure the cleanliness of the petri dish, before the experiment, the surface dish was ultrasonically cleaned for 30 minutes, then rinsed with deionized water three times, and finally dried in a drying oven for use in the experiment.

[0043]...

Embodiment 2

[0049] First accurately weigh the PVP powder equivalent to the sodium citrate crystal of the corresponding quality of 0.3mmol and the PVP powder of the corresponding quality of 0.1mmol with an electronic balance, and the deionized water of 11.03mL is used to dissolve the two kinds of medicaments in a beaker to form a uniform mixed solution ( The volume of the mixed solution can be more, but to ensure that the concentration of the two reagents is constant), that is, the chemical coating solution.

[0050] In order to ensure the consistency of the gold sheet target used in the ablation experiment, before each experiment, the size 10×10×0.5mm 3 The gold flakes with a purity of 99.99% were mechanically polished (using 1000# sandpaper), washed three times with deionized water, rinsed with absolute ethanol, and finally dried for use. In order to ensure the cleanliness of the petri dish, before the experiment, the surface dish was ultrasonically cleaned for 30 minutes, then rinsed wi...

Embodiment 3

[0055] First accurately weigh the PVP powder equivalent to the sodium citrate crystal of the corresponding quality of 0.3mmol and the PVP powder of the corresponding quality of 0.1mmol with an electronic balance, and the deionized water of 11.03mL is used to dissolve the two kinds of medicaments in a beaker to form a uniform mixed solution ( The volume of the mixed solution can be more, but to ensure that the concentration of the two reagents is constant), that is, the chemical coating solution.

[0056] In order to ensure the consistency of the platinum sheet target used in the ablation experiment, before each experiment, the size 10×10×0.5mm 3 , a platinum sheet with a purity of 99.99% was mechanically polished (using 1000# sandpaper), then washed three times with deionized water, then rinsed with absolute ethanol, and finally dried for use. In order to ensure the cleanliness of the petri dish, before the experiment, the surface dish was ultrasonically cleaned for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com