Pinpoint enhanced dark-field microscope, electrochemical testing device and leveling system

A dark-field microscope and electrochemical technology, which is applied in measuring devices, scanning probe microscopy, scanning probe technology, etc., can solve the problems of unstable test results, difficulty in approaching, and affecting the accuracy of results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method for producing near-field enhanced incident optical fiber probes, that is, the method for modifying the metal nanoparticles to the tip of the hollow optical fiber probe, includes: negative pressure suction method; electrodeposition method; sol method ; laser stretching method; seed crystal growth method.

[0055] The negative pressure inhalation method for preparing the incident optical fiber probe includes: dropping a solution medium dispersed with noble metal nanoparticles on the surface of a glass slide; sealing the outer port of the drawn optical fiber probe; , the probe nozzle is aimed at the nanoparticles in the solution medium; negative pressure is applied to the fiber port; the noble metal nanoparticles are sucked into the nozzle.

[0056] The electrodeposition method for preparing the incident optical fiber probe includes: using a laser drawing method to obtain an optical fiber probe with a tip aperture; electroless silver plating on the i...

Embodiment 1

[0085] Preparation of LSPR-coupled probes

[0086] (1) Preparation of seed crystal solution:

[0087] The preparation method of the seed crystal solution under the protection of cetyltrimethylammonium bromide (CTAB): sequentially transfer 7.5mL CTAB (0.1M), 0.25mL chloroauric acid (10mM) and 2.5mL ultrapure water into a 10mL round bottom In a flask, mix evenly, place until clear, the color is bright yellow, and store in a constant temperature water bath at 28-30°C for later use. Place the ultrapure water (washing bottle) in ice water to cool for more than 15 minutes, rinse the volumetric flask for preparing sodium borohydride several times with cooled ultrapure water, then prepare 50mL of 10mM sodium borohydride solution with ice water, place in Set aside in ice water. The cooling time of ultra-pure water is better to put one or several drops of ultra-pure water on the fingers to feel freezing. Under stirring conditions, quickly inject 0.6 mL of sodium borohydride aqueous sol...

Embodiment 2

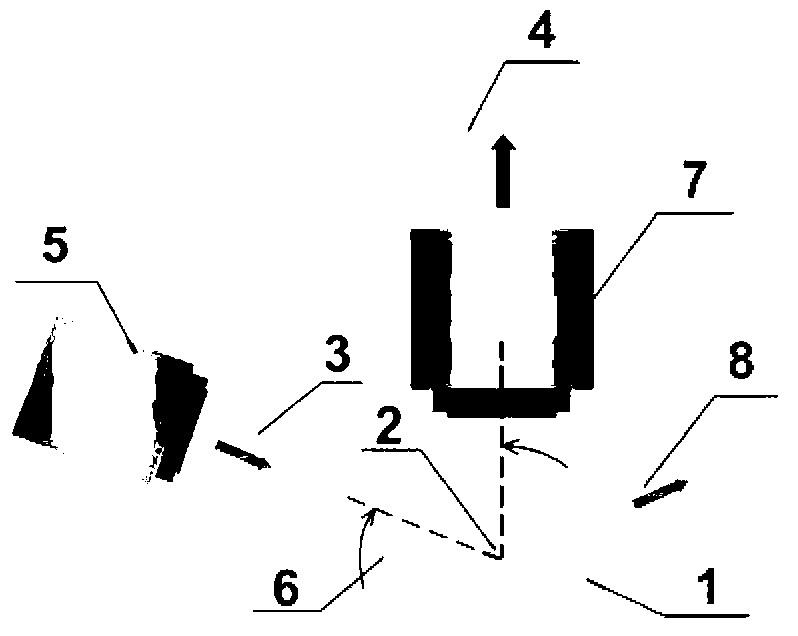

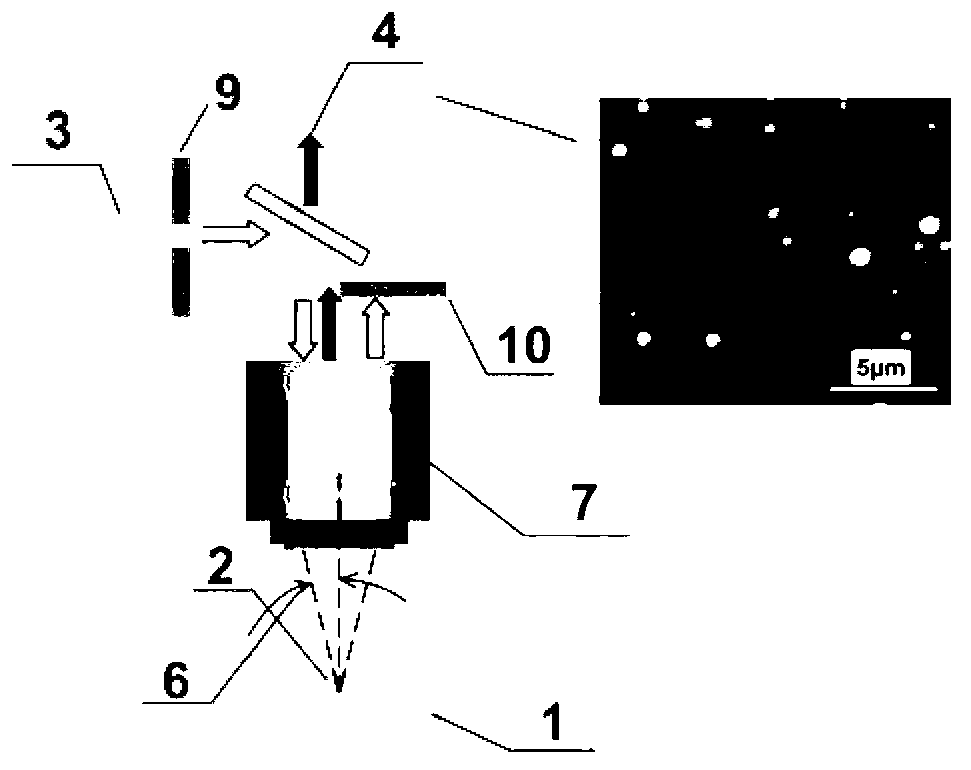

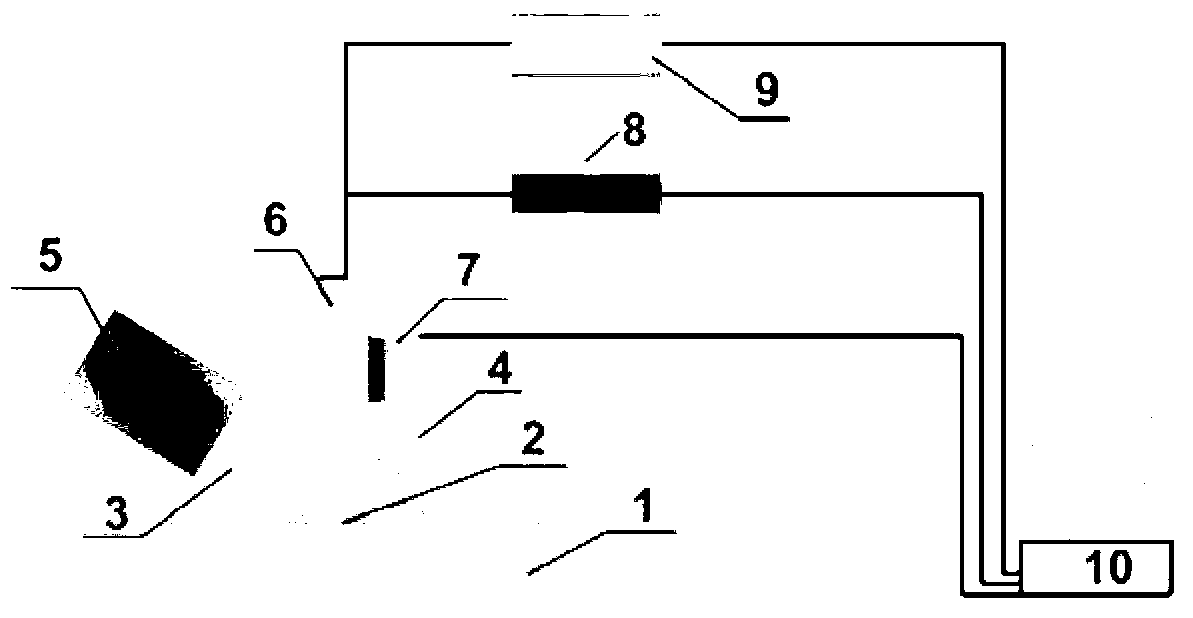

[0092] Build the inventive tip-enhanced dark-field microscope device shown in Figure 4(a). In the example shown in Figure 6, the prepared spherical gold nanoparticles with a particle size of about 150 nm were filled into the tip of the laser-drawn hollow fiber by negative pressure suction (Figure 6(b)). The particle sizes of the nanoparticles are approximately equal, and the prepared optical fiber probe is shown in Figure 6(c). The white area in the middle is confirmed to be gold nanoparticles by elemental analysis, which is used for near-field coupling with the substrate 5 . The fiber optic probe shown in Fig. 6(c) was installed on the inventive tip-enhanced dark-field microscope device shown in Fig. 4(a) as the incident fiber. As shown in Figure 4(a), six solid optical fibers 3 are placed outside the incident fiber to form a fiber bundle 4. The fiber bundle is wrapped by rubber light-proof material, and visible light passes through the incident fiber 2, and gold nanoparticle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com