Soy protein isolate/hyaluronic acid/sodium carboxymethyl cellulose composite film and preparation method thereof

A technology of sodium carboxymethyl cellulose and soybean protein isolate, which can be applied in sustainable manufacturing/processing, flexible covering, biological packaging, etc., can solve the problems of non-degradable white pollution, shortage of raw material oil, human harm, etc. Achieve the effect of good application potential, good barrier ability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Configuration of film-forming material solution

[0028] Dissolve 4g soybean protein isolate in 100mL deionized water, stir and dissolve at 60°C for 15min, then raise the temperature to 85°C for modification for 30min, cool to room temperature for later use; dissolve 4g hyaluronic acid and 2g sodium carboxymethylcellulose in 100mL of deionized water was used to make a polymer solution for later use.

Embodiment 2

[0029] Configuration of embodiment 2 composite membrane

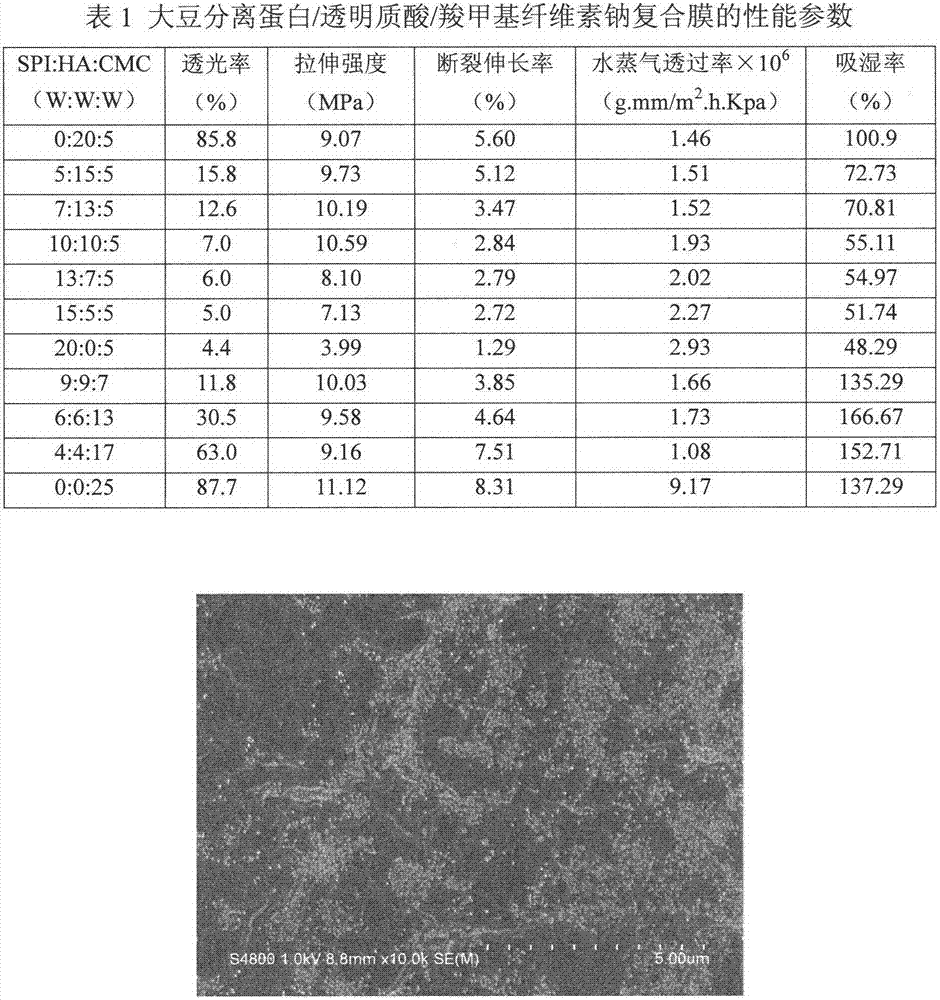

[0030] Mix the soybean protein isolate solution with the hyaluronic acid solution, then add the sodium carboxymethyl cellulose solution, and finally add the plasticizer glycerin with 10% of the total mass of the three film-forming materials, stir magnetically for 5 minutes to make the film-forming liquid mix evenly, and Add a small amount of absolute ethanol to defoam, drool on a glass plate to form a film, dry at 40°C for 24 hours, remove the film and place it in a 53% RH humidistat for more than 48 hours. See Table 1 for the changes in the ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com