Foam concrete block produced with waste ash and manufacturing method thereof

A technology of foamed concrete and a manufacturing method, which is applied in the field of manufacturing foamed concrete blocks and foamed concrete blocks with garbage ash, and can solve problems such as water resource pollution, human health hazards, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Garbage ash, which is the daily domestic garbage of residents and all kinds of garbage cleaned by the office space, large shopping malls, farmers' markets, landscaping, and sanitation systems on roads, streets, squares, parks, and other public places, is discharged after incineration and power generation After sorting, crushing, and magnetic separation to remove waste metal, and then crushing, drying, grinding, and sieving, the waste residue is made into powder with a particle size of less than 0.045mm for use;

[0047] The discarded polystyrene foam is used by the manufacturer to ensure the safety of high-end industrial products, household appliances and other valuable and fragile commodities during transportation. The padded packaging materials and disposable tableware produced by polystyrene, these commodities arrive The packaging is discarded in the hands of consumers, resulting in a large amount of discarded foamed plastics, referred to as white garbage, which is ma...

Embodiment 2

[0051] Take 0.8kg of sodium dodecylbenzenesulfonate foaming agent, 0.4kg of polyacrylamide foam stabilizer and 24kg of water and mix evenly to make a diluted foaming liquid. After filtering, store it in the storage tank and seal it for later use. It is automatically pumped into the foaming machine, and foamed by a high-pressure air foaming machine to make foam;

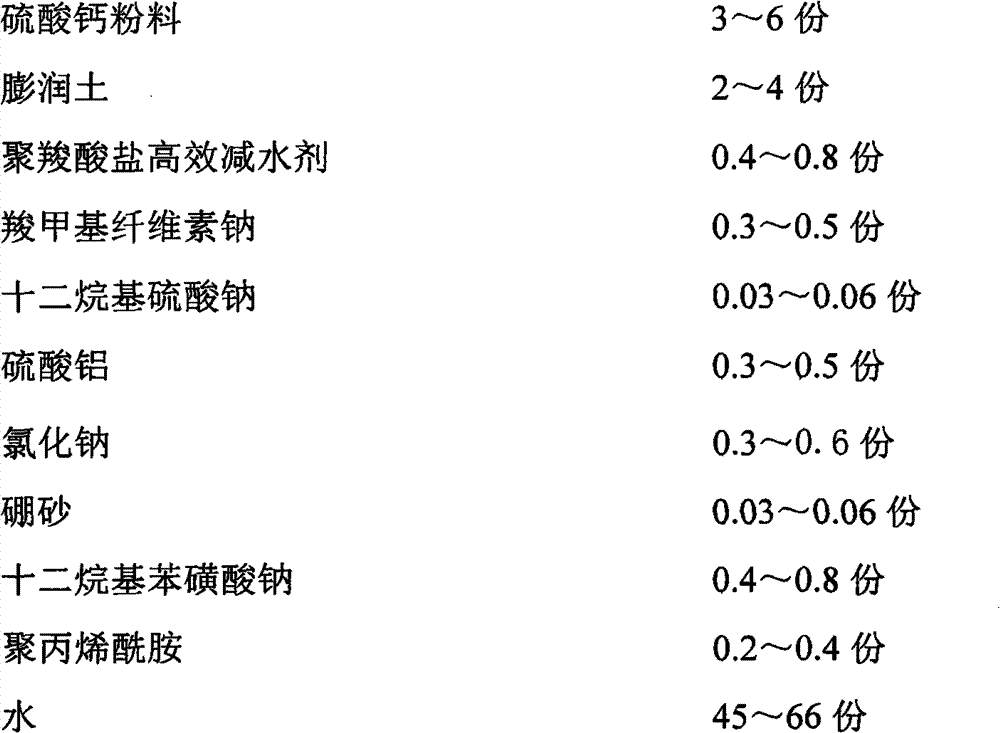

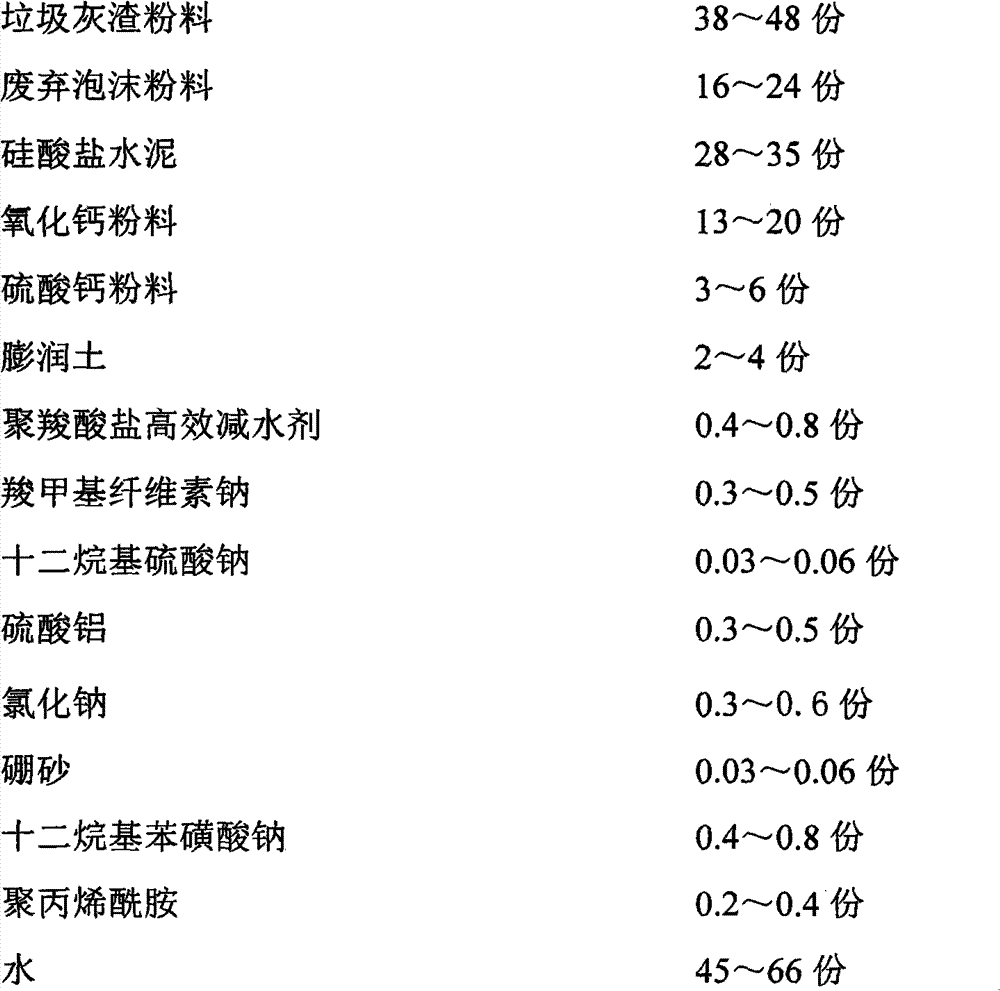

[0052] Get the rubbish ash powder material 48kg that embodiment 1 prepares, waste polystyrene foam powder material 24kg, Portland cement 35kg, calcium oxide powder material 20kg, calcium sulfate powder material 6kg, bentonite 4kg, polycarboxylate high-efficiency water-reducing 0.8kg of sodium carboxymethylcellulose, 0.5kg of sodium carboxymethyl cellulose, 0.06kg of sodium lauryl sulfate, 0.5kg of aluminum sulfate, 0.6kg of sodium chloride, 0.06kg of borax and 42kg of water, and the above raw materials were stirred evenly The mixture is made, and it is fully controlled by a microcomputer. The spiral tube conveyor is u...

Embodiment 3

[0054] Take 0.5kg of sodium dodecylbenzenesulfonate foaming agent, 0.3kg of polyacrylamide foam stabilizer and 15kg of water and mix evenly to make a diluted foaming liquid. After filtering, store it in the storage tank and seal it for later use. It is automatically pumped into the foaming machine, and foamed by a high-pressure air foaming machine to make foam;

[0055] Get the rubbish ash powder material 38kg that embodiment 1 prepares, waste polystyrene foam powder material 18kg, Portland cement 30kg, calcium oxide powder material 15kg, calcium sulfate powder material 4kg, bentonite 2kg, polycarboxylate efficient water-reducing 0.5kg of sodium carboxymethyl cellulose, 0.04kg of sodium lauryl sulfate, 0.3kg of aluminum sulfate, 0.4kg of sodium chloride, 0.04kg of borax and 36kg of water, and the above raw materials were stirred evenly with a biaxial mixer The mixture is made, and it is fully controlled by a microcomputer. The spiral tube conveyor is used to send the mixture t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com