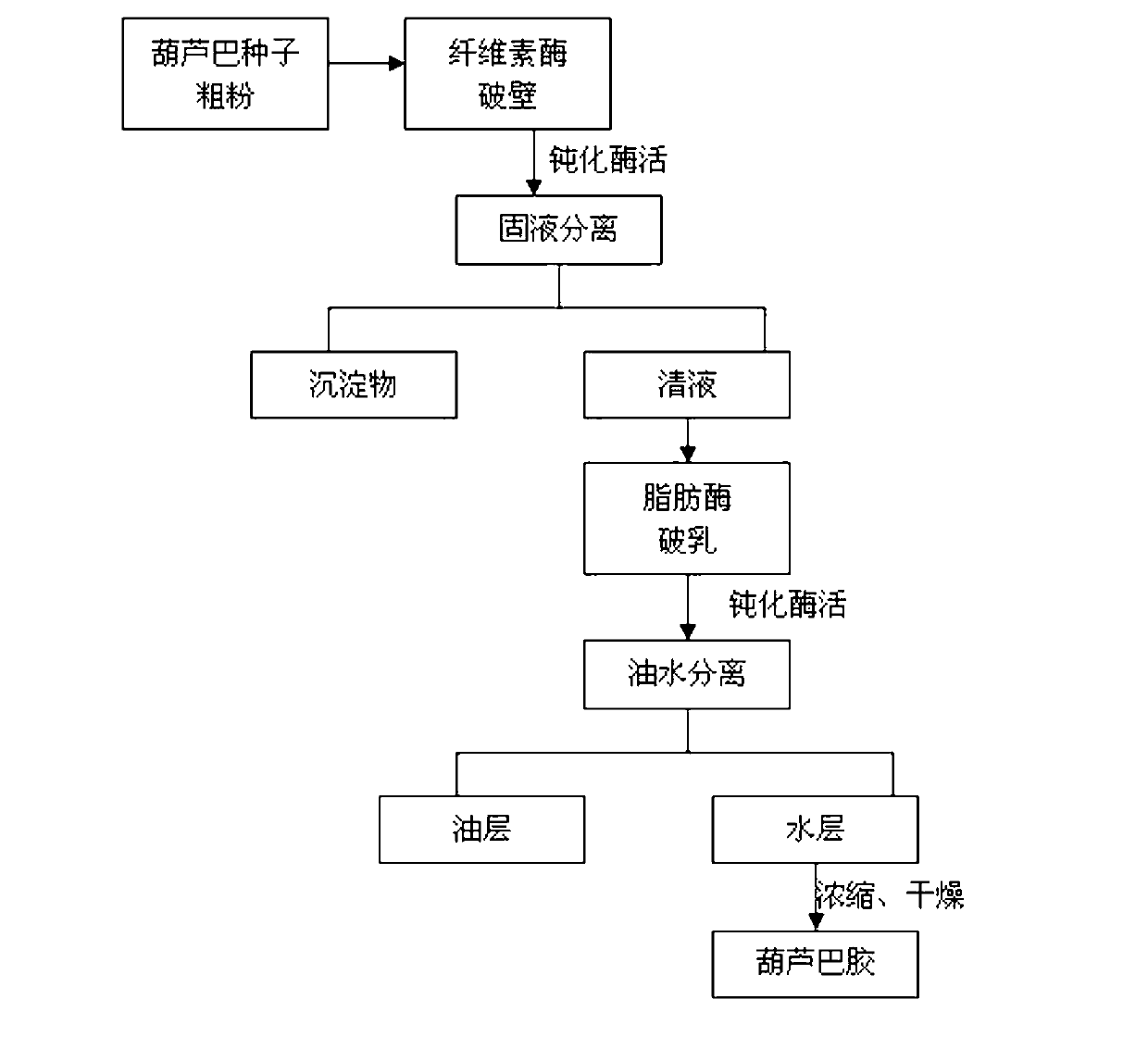

Method for extracting bottle gourd Pakistan rubber by dual-enzyme coupling

A technology of fenugreek gum and coupling method, which is applied in the field of double-enzyme coupling extraction of fenugreek gum, can solve the problems of changes in biological activity of natural products, time-consuming and labor-intensive extraction with hot water, and low extraction rate, so as to shorten the time , mild reaction conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Weigh 200g of dried fenugreek seeds, crush them in a pulverizer, pass through a 200-mesh sieve, add them into 10000mL of distilled water, stir to dissolve them fully; add 0.4g of cellulase, adjust the pH to 4.5, and control the extraction The temperature is 65°C, extract for 3 hours, then raise the temperature to 85°C to inactivate cellulase, collect the extract, cool to room temperature, centrifuge at 4000 rpm, collect the supernatant, and obtain substance A;

[0019] 2) Add 1.2g of lipase to substance A, adjust the pH=6.0, control the extraction temperature and extract at 30°C for 3.5h, then raise the temperature to 68°C to inactivate the lipase, collect the extract, cool to room temperature, and pass through the oil-water separator Separate and collect the water layer to obtain substance B;

[0020] 3) Substance B was concentrated under reduced pressure at 0.07Mpa to 1 / 6 of the original volume, and ethanol was added to the concentrated solution so that the content...

Embodiment 2

[0022] 1) Weigh 150g of dried fenugreek seeds, crush them in a pulverizer, pass through a 200-mesh sieve, and dissolve them fully with 10500mL of distilled water; add 0.6g of cellulase under stirring, adjust the pH to 3.0, and control the extraction temperature to 50 ℃, extract for 2 hours, then raise the temperature to 80 ℃ to inactivate cellulase, collect the extract, cool to room temperature, centrifuge at 4200 rpm, collect the supernatant, and obtain substance A;

[0023] 2) Add 1.05g of lipase to substance A, adjust the pH=5.0, control the extraction temperature to 60°C, and extract for 4 hours; then raise the temperature to 70°C to inactivate the lipase, collect the extract, cool to room temperature, and pass through the oil-water separator Separate and collect the water layer to obtain substance B;

[0024] 3) Substance B is concentrated under reduced pressure at 0.08Mpa to 1 / 5 of the original volume, and ethanol is added to the concentrated solution so that the ethanol...

Embodiment 3

[0026] 1) Weigh 100g of dried fenugreek seeds, crush them in a pulverizer, pass through a 200-mesh sieve, dissolve them fully with 10,000mL of distilled water, add 0.5g of cellulase under stirring, adjust the pH to 6, and control the extraction temperature to 30 ℃, extract for 5 hours; then raise the temperature to 82 ℃ to inactivate cellulase; collect the extract, cool to room temperature, centrifuge at 5000 rpm, collect the supernatant, and obtain substance A;

[0027] 2) Add 1.0 g of lipase to substance A, adjust the pH to 8.0, control the extraction temperature to 50°C, and extract for 3 hours; then raise the temperature to 65°C to inactivate the lipase, collect the extract, cool to room temperature, and separate through an oil-water separator , collect the water layer to obtain substance B;

[0028] 3) Substance B was concentrated under reduced pressure at 0.09Mpa to 1 / 7 of the original volume, and ethanol was added to the concentrated solution so that the ethanol content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com