Ultraviolet-cured transparent halogen-free flame-retardant unsaturated polyester and preparation method thereof

An unsaturated and ultraviolet light technology, applied in the field of halogen-free flame retardant unsaturated polyester resin, can solve the problems of volatilization and loss, and achieve the effect of enhanced oxidation resistance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

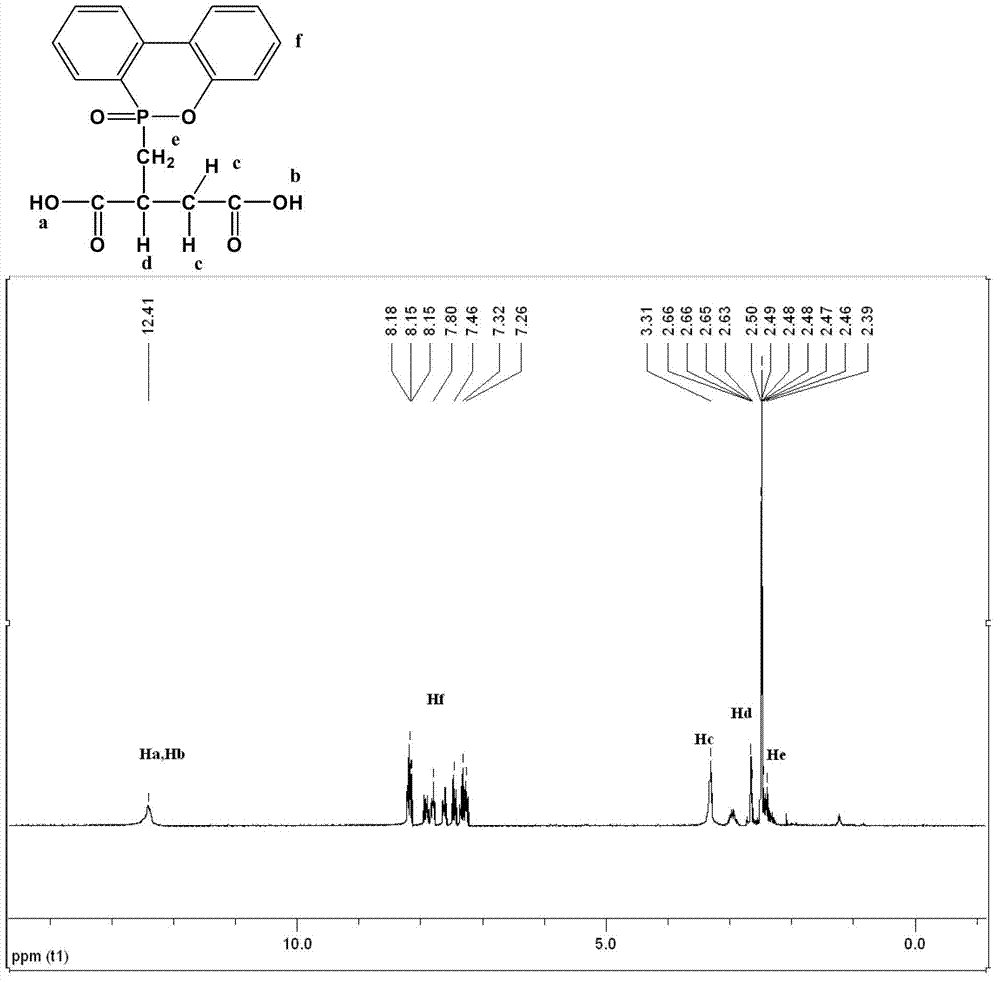

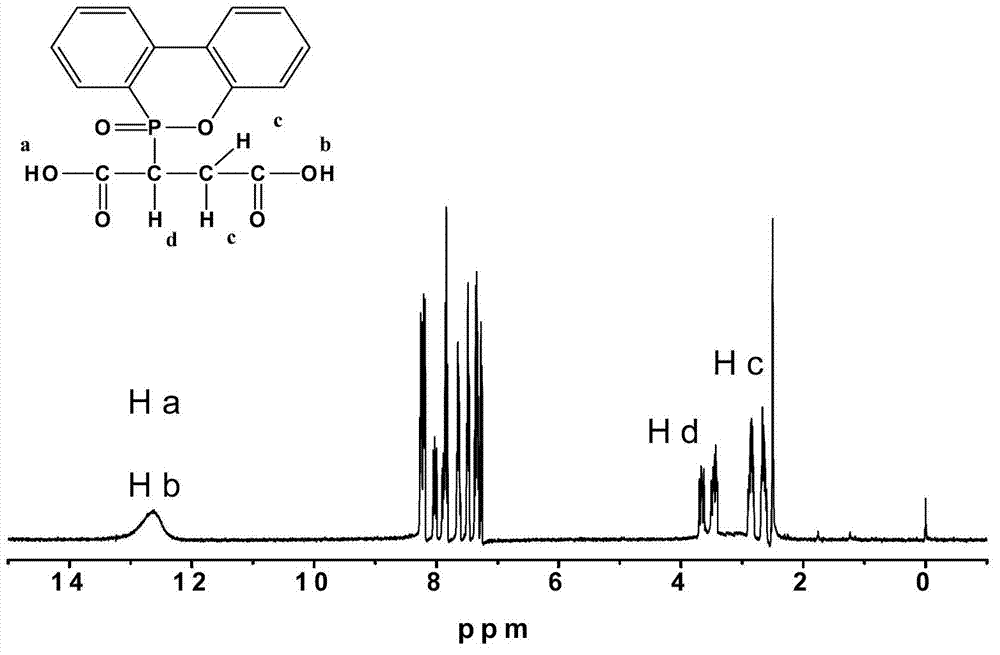

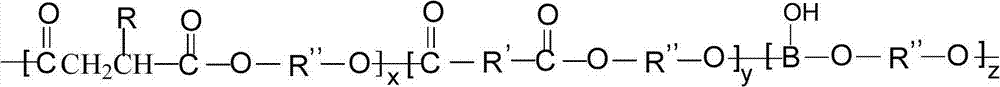

[0028] Add 1.2mol 1,3-propanediol, 0.55mol maleic anhydride, 0.2mol maleic anhydride and 9,10-dihydro-9-oxa-10- The addition product of phosphaphenanthrene-10-oxide (DOPO) and 0.25mol boric acid are heated up to 150-160°C, kept at a constant temperature for 2 hours, then heated up to 180-205°C for reaction, and the outlet temperature of the distillation is controlled to be lower than 100°C. Measure the acid value every 1 hour, stop heating when the acid value is lower than 40mg KOH / g, and cool to 100°C to obtain a phosphorus-boron flame-retardant unsaturated polyester prepolymer; add hydroxyethyl acrylate, cool to room temperature, and add After hydroquinone and benzoin butyl ether, stir at room temperature for 30 minutes to obtain UV-curable transparent halogen-free flame-retardant unsaturated polyester; 1 part of hydroxyethyl acrylate, 0.1 part of hydroquinone and 0.4 part of benzoin butyl ether. The general structural formula of the obtained phosphorus-boron flame-retardan...

Embodiment 2

[0032]Add 0.5mol ethylene glycol, 0.6mol 1,2-propanediol, 0.55mol maleic anhydride, 0.15mol maleic acid, 0.15mol itaconic anhydride and DOPO to a 500ml three-necked flask equipped with a thermometer, a stirrer, and a distillation branch pipe. Addition product and 0.15mol boric acid, heat up to 150-160°C, hold constant temperature for about 2 hours, then heat up to 180-205°C to react, control the distillation outlet temperature below 100°C, measure the acid value every 1 hour, when the acid value Stop heating when it is lower than 40mg KOH / g, cool to 120°C to obtain phosphorus boron flame retardant unsaturated polyester prepolymer; add hydroxyethyl acrylate and triethylene glycol diacrylate, cool to room temperature, add p-tert-butyl o- After hydroquinone and benzoin dimethyl ether (Irgacure 651), stir at room temperature for 60 minutes to obtain UV-curable transparent halogen-free flame-retardant unsaturated polyester; polymer, 32 parts hydroxyethyl acrylate, 13 parts triethyl...

Embodiment 3

[0036] Add 0.65 mol of diethylene glycol, 0.6 mol of 1,3-propanediol, 0.4 mol of maleic anhydride, 0.2 mol of fumaric anhydride, 0.2 mol of itaconic anhydride into a 500ml three-necked flask equipped with a thermometer, a stirrer, and a distillation branch pipe With the addition product of DOPO and 0.2mol boric acid, heat up to 150-160°C, keep the temperature for about 2 hours, then raise the temperature to 180-205°C to react, control the distillation outlet temperature to be lower than 100°C, and measure the acid value every 1 hour. Stop heating when the acid value is lower than 40mg KOH / g, and cool to 110°C to obtain a phosphorus-boron flame-retardant unsaturated polyester prepolymer; add hydroxyethyl acrylate, propoxylated neopentyl glycol diacrylate and three Methylol propane triacrylate, cooled to room temperature, after adding methyl hydroquinone and 4,4-dimethylaminobenzophenone (Michler's ketone), stirred at room temperature for 40 minutes to obtain UV-curable transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com