Composite material and preparation method thereof

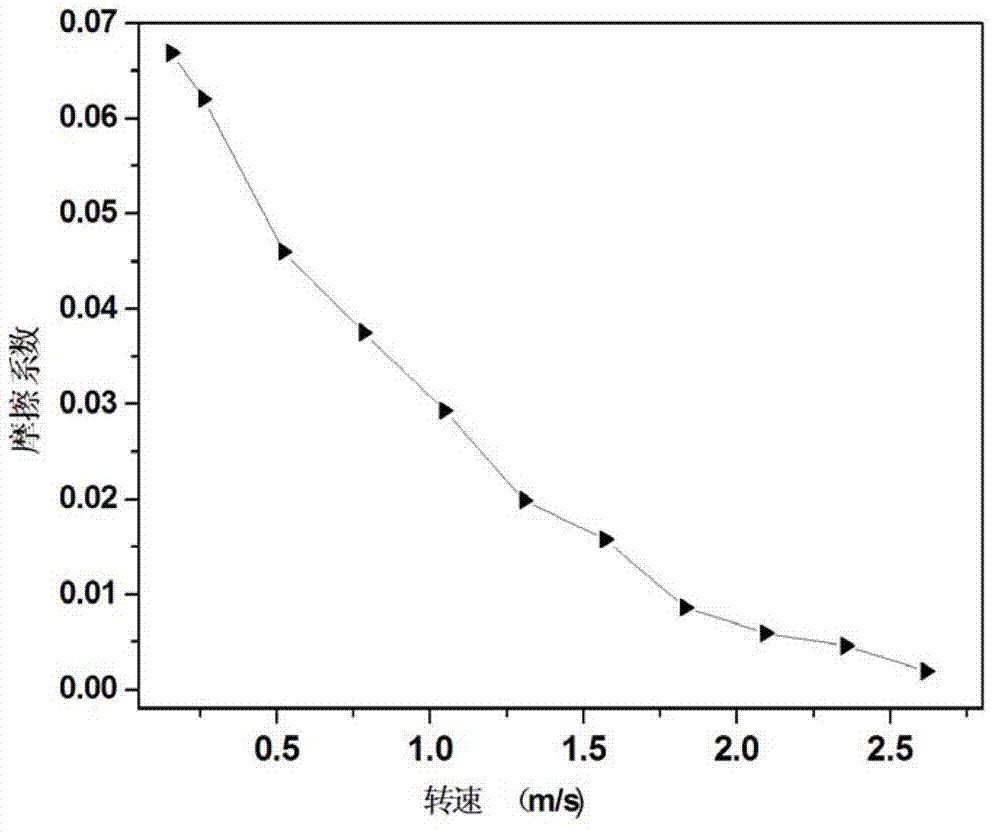

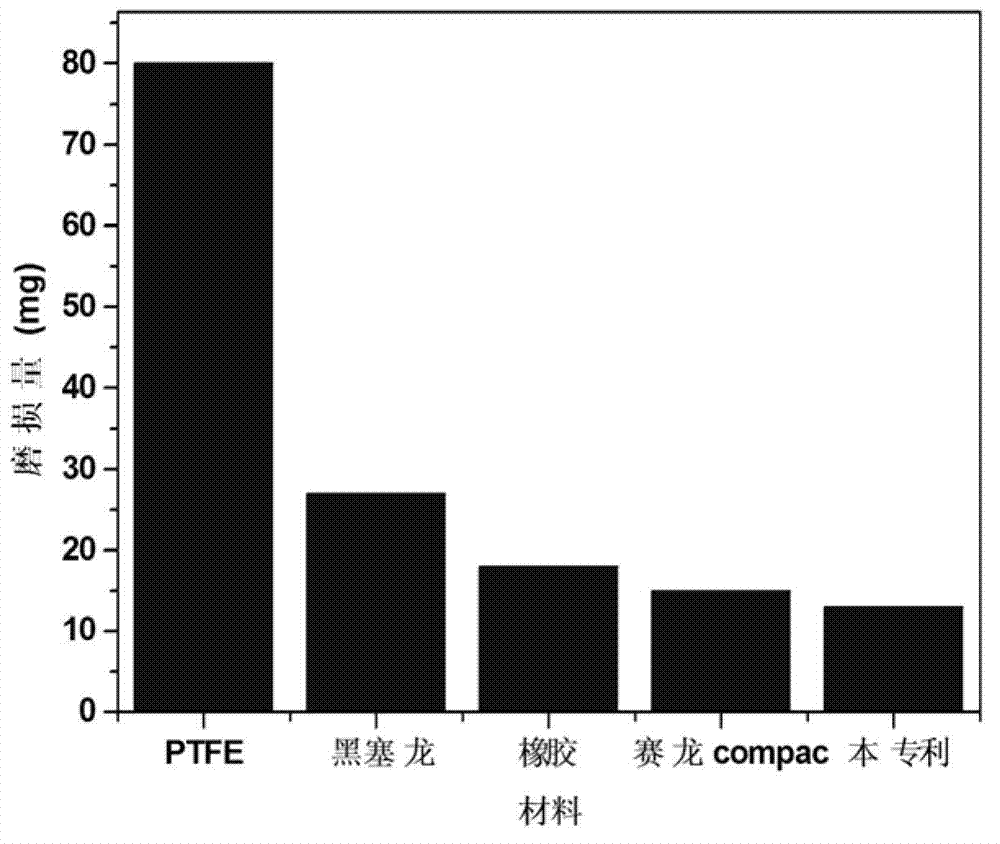

A composite material and rubber technology, which is applied in the field of composite materials and its preparation, can solve the problems of poor self-lubricating performance, achieve the effects of simplifying the process flow, excellent self-lubricating performance, and avoiding complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a kind of preparation method of composite material, comprises the following steps:

[0054] 90-110 parts by weight of rubber, 0.5-5 parts by weight of peroxide initiator, 4-30 parts by weight of crosslinking agent, 1-15 parts by weight of nano-titanium dioxide, 5-40 parts by weight of nano-silicon carbide, 5-30 parts by weight of ultra-high molecular weight polyethylene, 2-20 parts by weight of polytetrafluoroethylene, 2-20 parts by weight of glass fiber, 0-15 parts by weight of molybdenum disulfide, 0-15 parts by weight of graphite, 0-10 parts by weight of zinc oxide and 0-10 parts by weight of potassium hexatitanate are mixed in an internal mixer to obtain a rubber compound;

[0055] The mixed rubber is placed in a mould, and after press vulcanization, a composite material is obtained.

[0056] According to the present invention, as a preferred solution, the cavity temperature of the internal mixer is 20-100° C., and the spindle sp...

Embodiment 1

[0065] Heat the chamber of the internal mixer to 105°C, control the spindle speed at 25-30rpm, add 100 parts by weight of nitrile rubber raw rubber to the internal mixer, and add 0.5 parts by weight of stearic acid and 40 parts by weight of charcoal Black N220, 5 parts by weight of dicumyl peroxide (DCP), 5 parts by weight of trimethylolpropane trimethacrylate, 5 parts by weight of ultra-high molecular weight polyethylene powder, 1 part by weight of allyl Triethoxysilane, molybdenum disulfide of 10 parts by weight, polytetrafluoroethylene powder of 25 parts by weight, nano titanium dioxide of 15 parts by weight, nanometer silicon carbide of 30 parts by weight, glass fiber of 5 parts by weight, after the torque is constant, Control the spindle speed at 30-60rpm, continue mixing for 10 minutes, and then take out the mixed rubber. Transfer the mixed rubber to the double-roller mill for mixing. After mixing evenly, adjust the distance between the double-rollers of the mill to obta...

Embodiment 2

[0071] Heat the chamber of the internal mixer to 55°C, control the spindle speed at 25-30rpm, add 100 parts by weight of polyether polyurethane raw rubber to the internal mixer, add 0.5 parts by weight of stearic acid, 35 parts by weight of Silica, 14 parts by weight of ACTIGRAN 50 / 70, 2 parts by weight of dicumyl peroxide (DCP), 10 parts by weight of glyceryl methacrylate, 4 parts by weight of hydroquinone Two (2-hydroxyethyl) ether (HQEE), 10 parts by weight of ultra-high molecular weight polyethylene powder, 5 parts by weight of polytetrafluoroethylene powder, 10 parts by weight of nano-titanium dioxide, 8 parts by weight of nano-silicon carbide, 4 parts by weight 1010 parts by weight of ultraviolet absorber, 5 parts by weight of glass fiber, after the torque is constant, the spindle speed is controlled at 25-30 rpm, and the mixed rubber is taken out after continuing to knead for 10 minutes. Transfer the mixed rubber to a double-roller mill for mixing. During the mixing pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com