Method for preparing textural soya bean lecithin through molecular control technology

A technology of soybean lecithin and soybean lecithin, which is applied in the direction of fermentation and the like, can solve the problems of high reaction temperature, large energy consumption and high cost of industrialized production, and achieve the effects of mild reaction conditions, high conversion rate of raw materials and low solvent toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

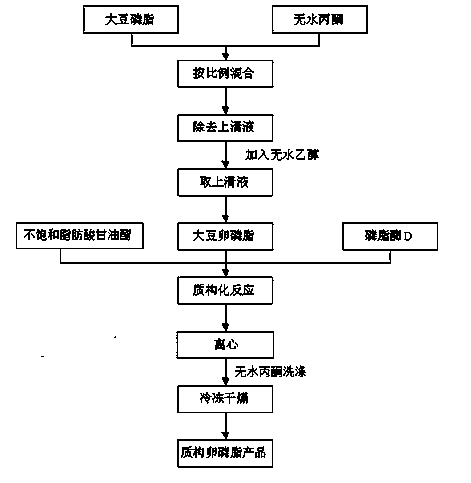

[0039] Process flow as attached figure 1 shown.

[0040] (1) In a thermostat at 60°C, stir and mix soybean lecithin (commercially available) with a mass ratio of 1:10 and anhydrous acetone. The stirring speed is 300 r / min, and the stirring time is 60 min. Centrifuge at high speed for 30 min, and remove the upper layer of acetone solution. Then add 5 times the mass of absolute ethanol, stir at 200 r / min for 30 min, let stand to separate layers, collect the ethanol solution, and repeat the operation 3 times. Concentrate under reduced pressure at 50°C and dry to obtain light yellow powdered soybean lecithin, and then use thin-layer chromatography to identify the obtained lecithin, and the results show that the lecithin has a purity of 58%.

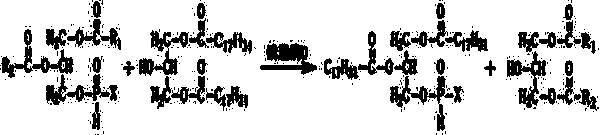

[0041] (2) In a thermostat at 60°C, stir and mix soybean lecithin and 1,3-linoleic acid diglyceride with a mass ratio of 1:9 at a stirring speed of 300 r / min for 90 min, then add Phospholipase D with 2% soybean lecithin mass was used to co...

Embodiment 2

[0048] (1) In a thermostat at 50°C, mix soybean crude phospholipids (commercially available) with a mass ratio of 1:6 and anhydrous acetone according to the specified conditions. The stirring speed is 200 r / min, and the stirring time is 45 min. Centrifuge at a speed of 1 / min for 20 min, and remove the upper acetone solution. Then add 4 times the mass of absolute ethanol, stir at a speed of 150 r / min for 20 min, let stand to separate layers, collect the ethanol liquid, and repeat the operation 3 times. Concentrate under reduced pressure at 50°C and dry to obtain light yellow powdered soybean lecithin, and then use thin-layer chromatography to identify the obtained lecithin, and the results show that the lecithin has a purity of 56%.

[0049] (2) In a thermostat at 50°C, fully stir and mix soybean lecithin and 1,3-eicosapentaenoic acid diglyceride at a mass ratio of 1:5, with a stirring speed of 200 r / min and a stirring time of 60 min , then add phospholipase D with 1.5% soybea...

Embodiment 3

[0055] (1) In a thermostat at 40°C, mix soybean crude phospholipids (commercially available) and anhydrous acetone at a mass ratio of 1:4, stir and mix thoroughly at a stirring speed of 100r / min for 30min, and then in 4000r / min Centrifuge at a rotational speed for 10 min, and remove the upper layer of acetone solution. Then add 3 times the mass of absolute ethanol, stir at 100 r / min for 10 min, let stand to separate layers, collect the ethanol solution, and repeat the operation twice. Concentrate under reduced pressure at 30°C and dry to obtain light yellow powdered soybean lecithin, and then use thin-layer chromatography to identify the obtained lecithin, and the results show that the lecithin has a purity of 52%.

[0056] (2) In a thermostat at 40°C, stir and mix soybean lecithin (prepared in step (1)) and 1,3-docosahexaenoic acid diglyceride with a mass ratio of 1:3. 100 r / min, stirring time 30 min, then adding phospholipase D with 1% soybean lecithin mass, controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com