Preparation method of lithium iron phosphate monocrystalline nanorods

A lithium iron phosphate, single crystal nanotechnology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem that the dynamic change of the crystal structure of the positive electrode material is difficult to achieve, and is not conducive to improving the energy density of lithium ion batteries, lithium iron phosphate The micro-morphology is difficult to control and other problems, so as to achieve the effect of facilitating the diffusion of lithium ions, improving the high-current charging and discharging performance, and facilitating large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

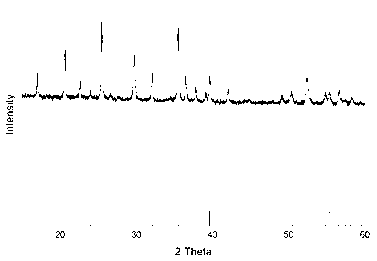

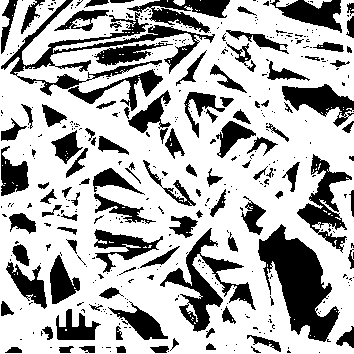

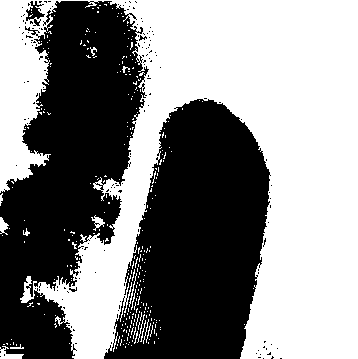

Image

Examples

example 1

[0022] The preparation method comprises the following steps:

[0023] 1) Measure 20ml of ethylene glycol and 20ml of deionized water, and mix them to prepare a mixed solvent of ethylene glycol and water.

[0024] 2) Measure and weigh 0.1 g of ascorbic acid and dissolve it in the mixed solvent of ethylene glycol and water prepared in step 1), and stir for 30 minutes to fully dissolve it.

[0025] 3) According to the mol ratio of P and Fe being 1:1, measure and weigh 0.4612g of phosphoric acid and 1.1121g of ferrous sulfate hexahydrate, and dissolve them in the ascorbic acid solution prepared in step 2), stir for 10 minutes, and obtain For the solution of iron and ascorbic acid, ascorbic acid accounts for 15.8% of the target lithium iron phosphate mass, the concentration of phosphoric acid is 0.1mol / L, and the concentration of ferrous sulfate hexahydrate is 0.1mol / L.

[0026] 4) According to step 3) the amount of phosphoric acid taken by weighing, the molar ratio of Li and P is...

example 2

[0034] 1) Measure 40ml of ethylene glycol and 40ml of deionized water, and mix them to prepare a mixed solvent of ethylene glycol and water.

[0035] 2) Measure and weigh 0.063g of ascorbic acid and dissolve it in the mixed solvent of ethylene glycol and water prepared in step 1), and stir for 30 minutes to fully dissolve it.

[0036]3) According to the mol ratio of P and Fe being 1:1, measure and weigh 0.4612g of phosphoric acid and 1.1121g of ferrous sulfate hexahydrate, and dissolve them in the ascorbic acid solution prepared in step 2), stir for 10 minutes, and obtain For the solution of iron and ascorbic acid, ascorbic acid accounts for 10% of the target lithium iron phosphate mass, the concentration of phosphoric acid is 0.05mol / L, and the concentration of hexahydrate ferrous sulfate is 0.05mol / L.

[0037] 4) According to step 3) the amount of phosphoric acid taken by weighing, the molar ratio of Li and P is 3:1, measure and take lithium hydroxide 0.5035g, be dissolved i...

example 3

[0041] 1) Measure 20ml of ethylene glycol and 20ml of deionized water, and mix them to prepare a mixed solvent of ethylene glycol and water.

[0042] 2) Measure and weigh 0.189g of ascorbic acid and dissolve it in the mixed solvent of ethylene glycol and water prepared in step 1), and stir for 30 minutes to fully dissolve it.

[0043] 3) According to the mol ratio of P and Fe being 1:1, measure and weigh 0.4612g of phosphoric acid and 1.1121g of ferrous sulfate hexahydrate, and dissolve them in the ascorbic acid solution prepared in step 2), stir for 10 minutes, and obtain A solution of iron and ascorbic acid, ascorbic acid accounts for 30% of the target lithium iron phosphate mass, the concentration of phosphoric acid is 0.1mol / L, and the concentration of hexahydrate ferrous sulfate is 0.1mol / L.

[0044] 4) According to step 3) the amount of phosphoric acid taken by weighing, the molar ratio of Li and P is 3:1, measure and take lithium hydroxide 0.5035g, be dissolved in the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com