Method for producing vitriol and calcium oxide by decomposing gypsum

A technology of calcium oxide and calcium sulfate, which is applied in chemical instruments and methods, sulfur compounds, calcium/strontium/barium oxides/hydroxides, etc., can solve the problem of various production raw materials, large fluctuations in kiln gas concentration, and uneven cement clinker. Stability and other issues, to achieve the effect of large-scale industrial production, easy control of the reaction atmosphere, and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

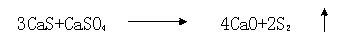

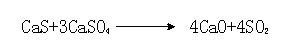

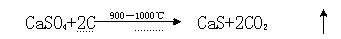

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] (1) After drying and dehydrating the desulfurized gypsum from a coal power plant with an external moisture content of 10wt%, the moisture content is 6wt%, and the dehydrated desulfurized gypsum and coke powder are mixed according to the mass ratio of 100:5, and then sent to FRMS vertical mill mixed and ground, the fineness is 0.08mm standard sieve, and the sieve residue is 20wt%;

[0033] (2) Send the raw material prepared in step (1) into the suspension preheater, and exchange heat with the 750°C kiln gas from the tail of the rotary kiln, so that the raw material is preheated to 600°C, and the kiln gas leaves the suspension preheater The temperature is 300-350°C;

[0034] (3) Send the preheated raw materials in step (2) into the rotary kiln for calcination and decomposition. At 900-1250°C, control the weak oxidation atmosphere in the kiln, and the air excess coefficient of pulverized coal combustion is 1.04, and c...

Embodiment 2

[0038] The calcium sulfate in this example is derived from phosphogypsum produced in the production of wet-process phosphoric acid, and its external moisture is 15wt%. After drying and dehydration, the mass ratio of phosphogypsum and coke powder is 100:6. Other steps and embodiments 1 is the same.

Embodiment 3

[0040] The raw material used in this embodiment is crushed natural anhydrite, whose lumpiness is less than or equal to 25mm, the natural anhydrite powder is directly compounded, and the crushed natural anhydrite and coke powder are batched according to the mass ratio of 100:8, and coke powder is mixed with coke powder Carry out grinding together, other is with embodiment 1.

[0041] When natural anhydrite is used as raw material, in step (3), the obtained kiln gas has a higher concentration and contains SO 2 10-12wt%, which is beneficial to the preparation of sulfuric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com