Preparation method of lanthanum phosphate nano-wires

A technology of lanthanum phosphate nano and salt solution, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., which can solve the problems of water pollution, low output, and damage to the ecological environment, and achieve the effects of reducing production costs and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing lanthanum phosphate nanowires according to an embodiment of the present invention comprises the following steps:

[0052] S01: Prepare La separately 3+ Saline solution and PO 4 3- saline solution;

[0053] S02: To the La 3+ Add the PO to the saline solution4 3- Salt solution, to get mixed solution I;

[0054] S03: stirring the mixed solution I, adjusting the pH value of the mixed solution I to 0.8-9.0 to obtain the mixed solution II;

[0055] S04: aging the mixed solution II at 4° C. to 95° C. for more than 1 hour under ambient pressure to obtain the lanthanum phosphate nanowires.

[0056] In step S01, the La 3+ Saline solution and PO 4 3- The saline solution was prepared with soluble La commonly used in this field. 3+ Salt and soluble orthophosphate PO 4 3- Salt is the solute and water is the solvent. For example, the soluble La 3+ The salt can be lanthanum nitrate, lanthanum chloride, etc., also including 2 o 3 Soluble La produce...

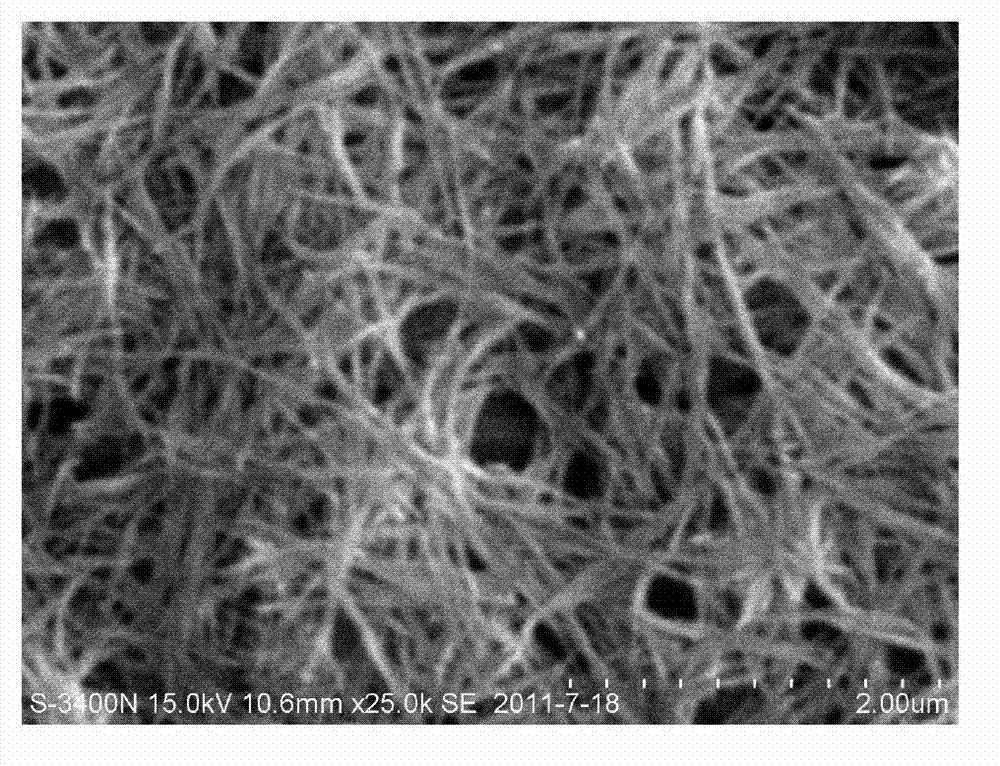

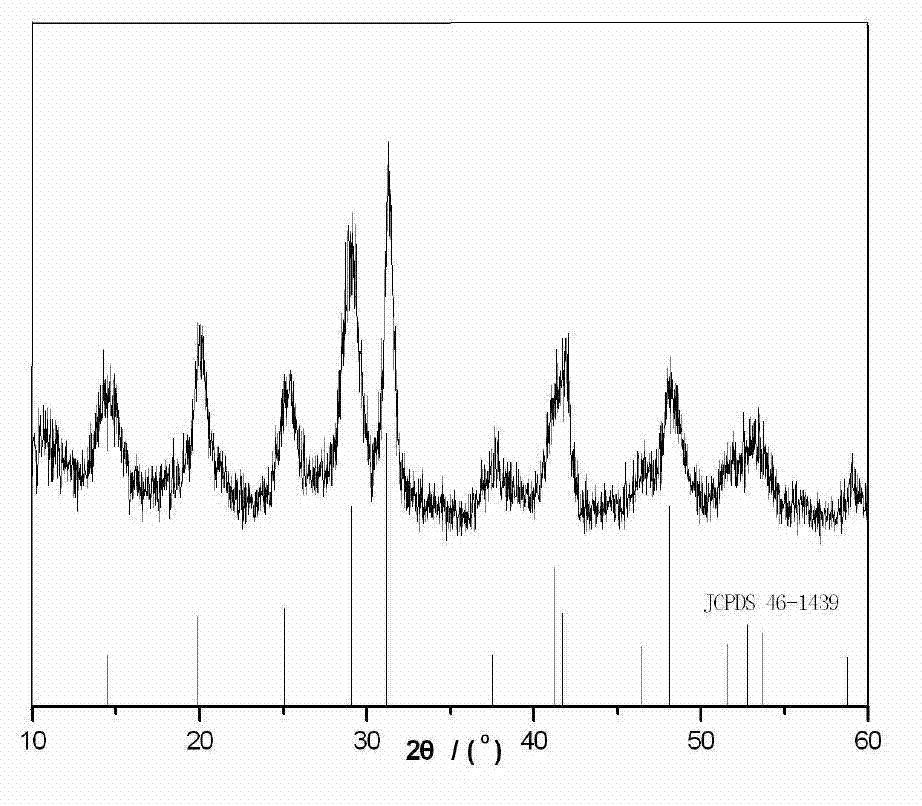

Embodiment 1

[0067] Weigh a certain mass of lanthanum nitrate [La(NO 3 ) 3 ·6H 2 O] and disodium phosphate [Na 2 HPO 4 12H 2 [0], be prepared with deionized water to be respectively 25 milliliters of lanthanum nitrate aqueous solution and disodium hydrogen phosphate aqueous solution that concentration is 0.1 mol / liter. The lanthanum nitrate solution was placed in a conical flask, stirred with a magnetic stirrer at a speed of 400 rpm, and the disodium hydrogen phosphate solution was dropped into the lanthanum nitrate solution while stirring. Stirring was continued for 1 hour, during which the pH value of the mixed solution was adjusted with 0.3 mol / L dilute phosphoric acid, and a certain amount of deionized water was added to make the pH value of the mixed solution 1.75, and the total volume was 80 ml. After stopping stirring, place the Erlenmeyer flask containing the mixed solution in a constant temperature water bath at 90°C, and age it under ambient pressure for 12 hours, then take ...

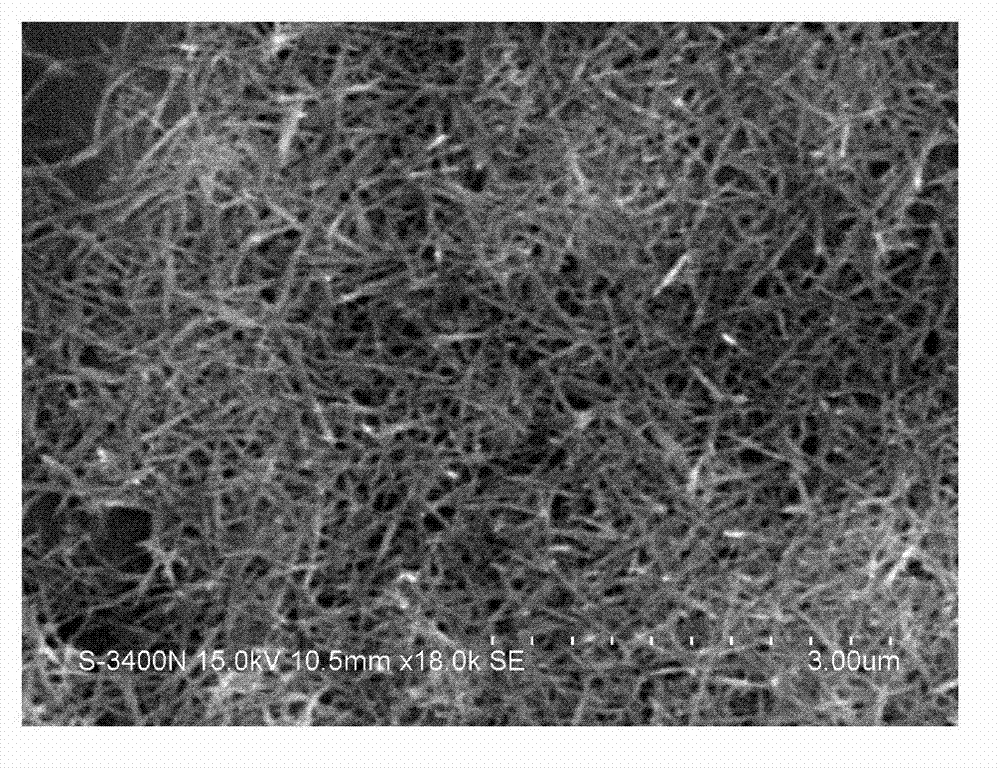

Embodiment 2

[0069] Weigh a certain mass of lanthanum nitrate [La(NO 3 ) 3 ·6H 2 O] and diammonium phosphate [(NH 4 ) 2 HPO 4], and deionized water was used to prepare respectively 25 milliliters of lanthanum nitrate aqueous solution and diammonium phosphate aqueous solution with a concentration of 0.1 mol / liter. The lanthanum nitrate solution was placed in a conical flask, stirred with a magnetic stirrer at a speed of 400 rpm, and the diammonium phosphate solution was dropped into the lanthanum nitrate solution while stirring. Stirring was continued for 1 hour, and 1 milliliter of orthophosphoric acid aqueous solution diluted to 10% was added during the period, and the pH value of this mixed solution was 1.64 (La in the mixed solution 3+ and PO 4 3- The molar concentration ratio is 0.6), and then add a certain amount of deionized water, so that the total volume of the mixed solution is 80 ml. After stopping the stirring, place the Erlenmeyer flask containing the mixed solution in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com