Composite type coal tar hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, coal tar technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. The problems of high catalytic activity and high cost of ore or iron sulfide ore can achieve excellent hydrogenation activity, improve catalyst activity, and high light oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

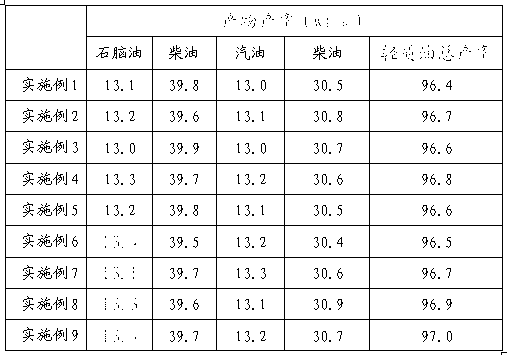

Examples

Embodiment 1

[0030] 131g of coal gangue was crushed into particles with a particle size of 300μm, and 2L of ammonium molybdate solution with a concentration of 0.5mol / L was evenly sprayed on the coal gangue particles. The coal gangue particles sprayed with ammonium molybdate solution were freeze-dried for 10 hours;

[0031] The coal gangue particles treated above are taken out from the negative pressure environment, and aged at normal temperature and pressure for 3 hours to obtain the coal tar hydrogenation catalyst of the present invention.

[0032] In the above catalyst, the content of the active component is 60wt%, and the content of the gangue carrier is 40wt%.

Embodiment 2

[0034] Crush 20g of coal gangue into particles with a particle size of 200μm, spray 2L of nickel nitrate solution with a concentration of 0.5mol / L evenly on the coal gangue particles, and spray them against each other at 0°C and a pressure of -0.3MPa Coal gangue particles drenched with nickel nitrate solution were freeze-dried for 8 hours;

[0035] The coal gangue particles treated above are taken out from the negative pressure environment, aged at normal temperature and pressure for 1.5 hours, and the coal tar hydrogenation catalyst of the present invention is obtained.

[0036] In the above catalyst, the content of the active component is 90wt%, and the content of the gangue carrier is 10wt%.

Embodiment 3

[0038] 63g of coal gangue was crushed into particles with a particle size of 150 μm, and 2 L of cobalt oxalate solution with a concentration of 0.5 mol / L was evenly sprayed on the coal gangue particles. Coal gangue particles sprayed with cobalt oxalate solution were freeze-dried for 5 hours;

[0039] The coal gangue particles treated above are taken out from the negative pressure environment, aged at normal temperature and pressure for 1 hour, and the coal tar hydrogenation catalyst of the present invention is obtained.

[0040] In the above catalyst, the content of the active component is 70wt%, and the content of the gangue carrier is 30wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com