Preparation method of graphene

A technology of graphene and graphite, which is applied in the field of two-dimensional nanomaterials and its preparation, can solve the problems of complex operation process, high toxicity and high production cost, and achieve the effect of wide application prospect, less impurity elements and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Dissolve 15 mL of concentrated H 2 SO 4 , 2.5g K 2 S 2 o 8 and 2.5g P 2 o 5 After mixing evenly, place in a beaker, heat to 80°C, add 5g of graphite powder into the beaker, react for 6h, wash, filter and dry.

[0027] Step 2: Add the graphite powder and sodium nitrate processed in step 1 to the concentrated 115mL H in an ice-water bath. 2 SO 4 Add potassium permanganate slowly under stirring, heat the oil bath to 35°C, react for 3 hours, then add deionized water, heat up to 98°C, keep warm for 0.5h, then dropwise add hydrogen peroxide with a mass fraction of 30% to reduce the unreacted Potassium permanganate, washed and centrifuged to obtain graphite oxide.

[0028] Step 3: Add the graphite oxide prepared in Step 2 into water, and then treat it under 300W ultrasonic power for 0.5h, centrifuge at 8000rpm for 5min, remove the precipitate, and obtain a 1mg / L graphite oxide dispersion.

[0029] Step 4: Add sodium diphenylamine sulfonate to the graphite oxid...

Embodiment 2

[0031] According to the preparation method of Example 1, only the reaction mass ratio of step 4 is changed to 30:0.407.

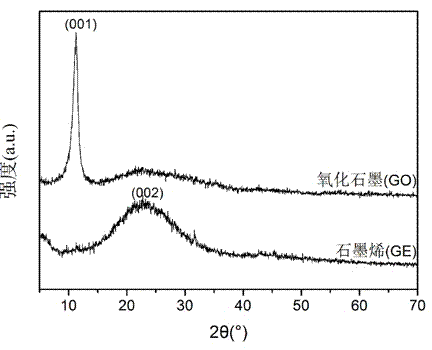

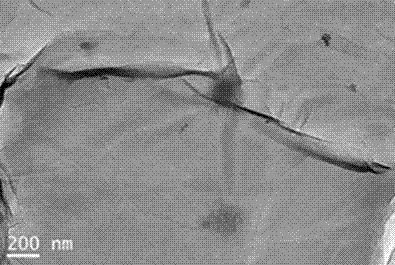

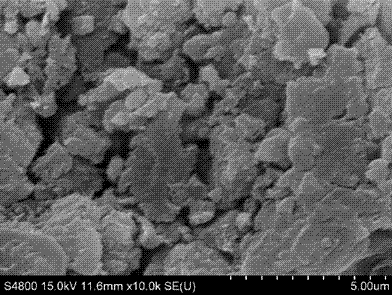

[0032] Figure 1 to Figure 4 The powder XRD diffraction spectrogram, the transmission electron microscope figure, the scanning electron microscope and the Raman spectrogram of the graphene that the present embodiment makes are provided respectively, find out from the powder XRD diffractogram, the (001) diffraction peak of graphite oxide is 11.28 ° , after the reduction reaction with sodium diphenylamine sulfonate, the (002) diffraction peak appeared at 23.14°; from the transmission electron microscope and scanning electron microscope, it can be seen that the graphene sheets have folds and stacked on each other; from the Raman spectrum, The D peak of graphene oxide appears at 1350 cm -1 and G peak at 1602 cm -1 , the D peak of graphene is at 1347cm -1 And the G peak is at 1598cm -1 , similar to related reports, the results show that graphene is prepared...

Embodiment 3

[0034] Press the preparation method of embodiment 1, just change the reaction mass ratio of step 4 into 30:0.542, Figure 5 It is the powder XRD diffraction spectrogram of the graphene of the present embodiment, and the results show that graphene is prepared by the method of the present invention, and the transmission electron microscope figure, scanning electron microscope and Raman spectrum figure are similar to embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com